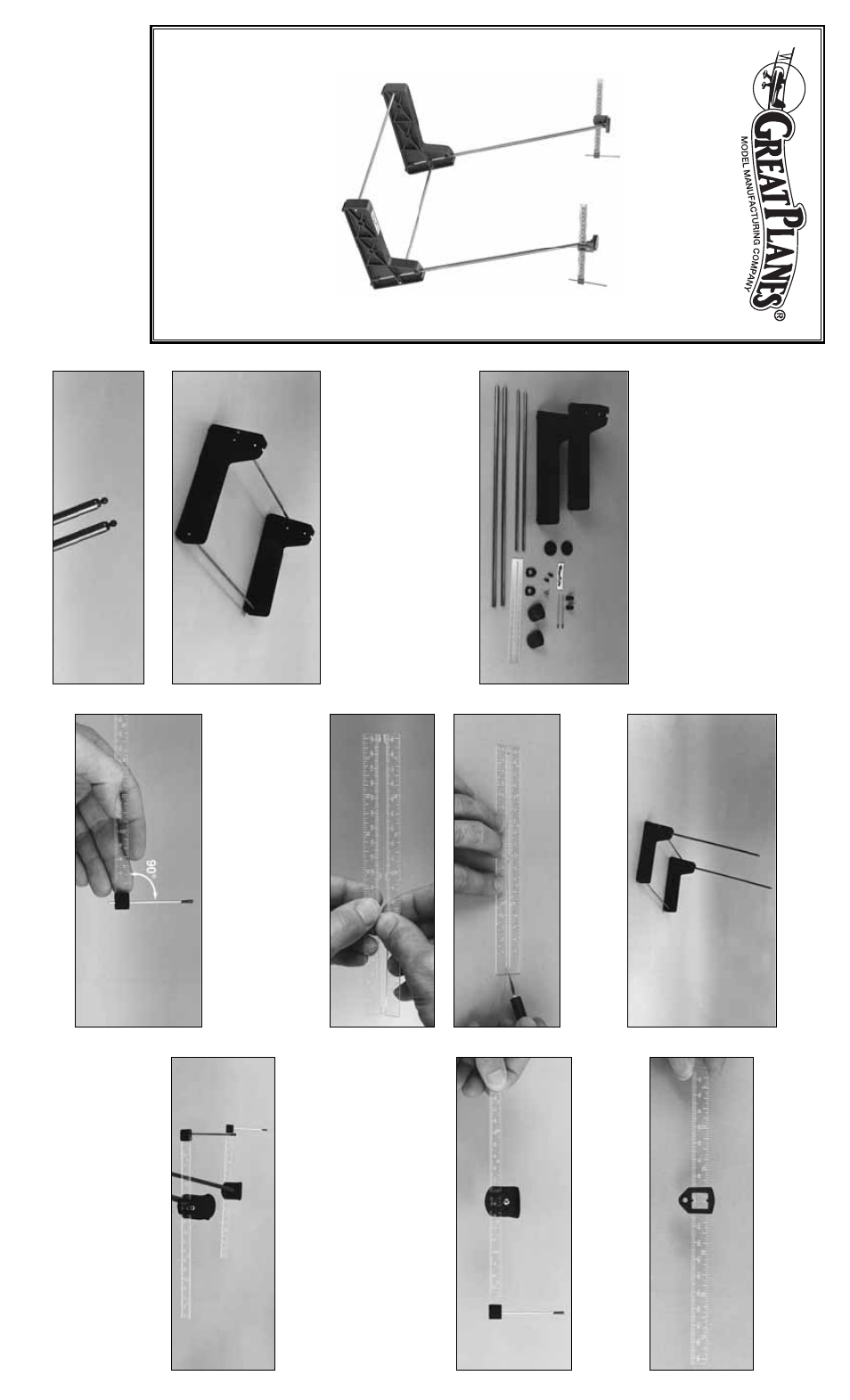

Great Planes CG Machine - GPMR2400 User Manual

C.g. ma chine, Assembl y instr uctions

Undoubtedly

, y

ou ha

v

e

an air

plane on which y

ou are anxious to test

y

our C

.G.

Machine

, so let’

s get star

ted!

T

OOLS AND SUPPLIES REQ

UIRED FOR ASSEMBL

Y

:

Thic

k or medium CA

Hob

b

y

knif

e

Phillips scre

wdr

iv

er

Small metal file

Thread loc

king compound

600 & 220-g

rit sandpaper

Small 90° tr

iangle

Tissue or paper to

w

e

l

Rub

bing alcohol or glass cleaner

C.G.

MA

CHINE P

A

R

T

S

❏

1.

Examine all molded plastic par

ts

, and tr

im off an

y mold flashing

with a shar

p hob

b

y

knif

e

.

Examine the ends of the metal rods f

o

r

b

urrs

, and carefully remo

v

e

them with a metal file or emer

y cloth.

ASSEMBL

Y SEQ

UENCE

❏

2.

Inser

t the tw

o 3/16" x 12" steel

base joiner r

ods

into the holes

in one of the molded plastic

bases

.

Both of the bases are the same

so there is not a

right

or a

left

.

The joiner rods should fit sn

ug, b

ut if

the

y are too tight, lightly lubr

icate them with bar soap

.

If the rods are

still too tight, carefully enlarge the holes in the base with a 3/16" dr

ill

bit or a round file

.

❏

3.

Join the other base to the joiner rods the same w

a

y.

❏

4.

Thread the tw

o 2-56 threaded steel

piv

ot balls

into the ends of

the 1/4" steel

upright r

ods

with a drop of thread loc

king compound.

Carefully remo

v

e

an

y b

urrs on the piv

ot balls with a small file

.

Clean

the piv

ot balls with a tissue

.

❏

5.

Push the 1/4" steel upr

ight rods

all the wa

y

into the bases

.

If

there is m

uch resistance

, carefully enlarge the holes with a 1/4" dr

ill

bit or a round file

.

❏

6.

The plastic r

uler set consists of tw

o

ruler

s

, connected

b

y

three

tabs

.

Use a hob

b

y

knif

e to cut par

t-w

a

y

through each tab on

both

sides

of the r

ulers

, then carefully fle

x and snap the r

ulers apar

t.

T

rim

the remaining tabs flush with the edge of the r

ulers

,

then finish with a

flat sanding b

loc

k and 220-g

rit or finer sandpaper

.

❏

7.

Inser

t the .074" x 2-1/2" wire

pointer

s

into the plastic

ruler end

caps

.

This should be a secure fr

iction fit.

❏

8.

Slide the r

uler end caps onto the r

ulers

.W

hen the r

uler end caps

are fully seated, the pointers should be per

pendicular to the r

u

ler – y

o

u

can use a small 90° tr

iangle to chec

k.

If it is necessar

y to adjust the

fit, sand the end of the r

uler slightly or tr

im the slot in the r

u

ler end cap

.

❏

9.

Apply a drop of thic

k or medium CA to both sides of the r

uler

at

the “z

er

o”

end,

inser

t the r

uler fully into the slot in the end cap

, then

immediately confir

m that the pointer wire is v

e

rtical.

Attach a r

uler end

cap to each of the r

ulers

.

❏

10.

Chec

k the fit of the r

ulers in the molded plastic

ruler holder

s

.

The r

ulers should slide freely in the r

uler holders

.

If the

y do not,

carefully sand the edges of the r

ulers with a sanding b

loc

k and fine

sandpaper until the r

ulers slide freely

.

❏

11.

Loosely attach the r

uler holder to the molded plastic

soc

ket cap

with a #4 x 3/8" scre

w

.

❏

12.

Inser

t the r

uler through the r

uler holder

, then tighten the scre

w

only enough to pro

vide fr

iction.

Do not o

v

er

tighten the scre

w

, as this

ma

y def

or

m the plastic.

❏

13.

Clean the top of the soc

k

et caps with a tissue or paper to

w

e

l

dampened with r

u

b

bing alcohol or glass cleaner

.

P

eel off the bac

king

from the f

oam r

u

b

ber

pads

, then apply the pads to the tops of the

soc

k

et caps

.

❏

14.

Snap the soc

k

et caps onto the steel balls on the upr

ight rods

.

There is not a front or a rear to the C

.G.

Machine so at this time it does

not matter onto which upr

ight rod y

ou install the soc

k

et caps

.

❏

15.

Piv

ot the soc

k

et caps throughout their r

ange of motion to chec

k

for free mo

v

ement.

If there is a significant amount of fr

iction betw

een

the cap and the ball, remo

v

e

the cap and snap it on again, mo

ving

and spinning it around.

If there is still too m

uch fr

iction, polish the steel

ball with 600-g

rit sandpaper and coat it with a thin film of bar soap

.

❏

16.

Apply the peel-and-stic

k decal to the top edge of one of

the bases

.

C.G.

MA

CHINE

™

ASSEMBL

Y INSTR

UCTIONS

Thank y

ou f

or purchasing the Great Planes

®

C.G.

Mac

hine

.

W

e are

glad y

ou realiz

e the impor

tance of proper

ly balancing y

our model

and the eff

ects the C

.G.

location has on the w

a

y it flies

.

Although

chec

king the C

.G.

is often one of those last min

ute

“oh, I’

d better do

that bef

ore I get to the flying field”

procedures

, the C

.G.

location can

ha

v

e

a prof

ound eff

ect on the w

a

y all models handle and respond to

control inputs

.Theref

ore

, deter

mining and shifting y

our model’

s

C

.G.

is an oper

ation that y

ou should perf

or

m with care and accur

acy

.

That’

s

where the Great Planes C

.G.

Machine comes into pla

y.

With

the Great Planes C

.G.

Machine

, y

ou can accur

ately and easily

balance y

our model according to the man

uf

acturer’

s

recommendations

,

and then mak

e incremental changes to the C

.G.

location to alter y

our

model’

s flight char

acter

istics according to y

our flight skills

and pref

erences

.

Great Planes Model Man

ufacturing

P

.O

.

Bo

x 788

Urbana, Illinois 61801

(217) 398-8970

Entire Contents © Cop

yr

ight 2004

BALP01 v1.1

Not designed f

o

r

use with planes

under 2 lbs

fl

ying weight.