0 technical tips, Which water should you use in your bath, How to prevent rust in water baths – Grant Instruments SBB Aqua Plus User Manual

Page 16

29825 Ver. 2 - July 2010 71W

SUB, JB & SBB Aqua Plus

Page 15

Operating Manual

www.grant.co.uk

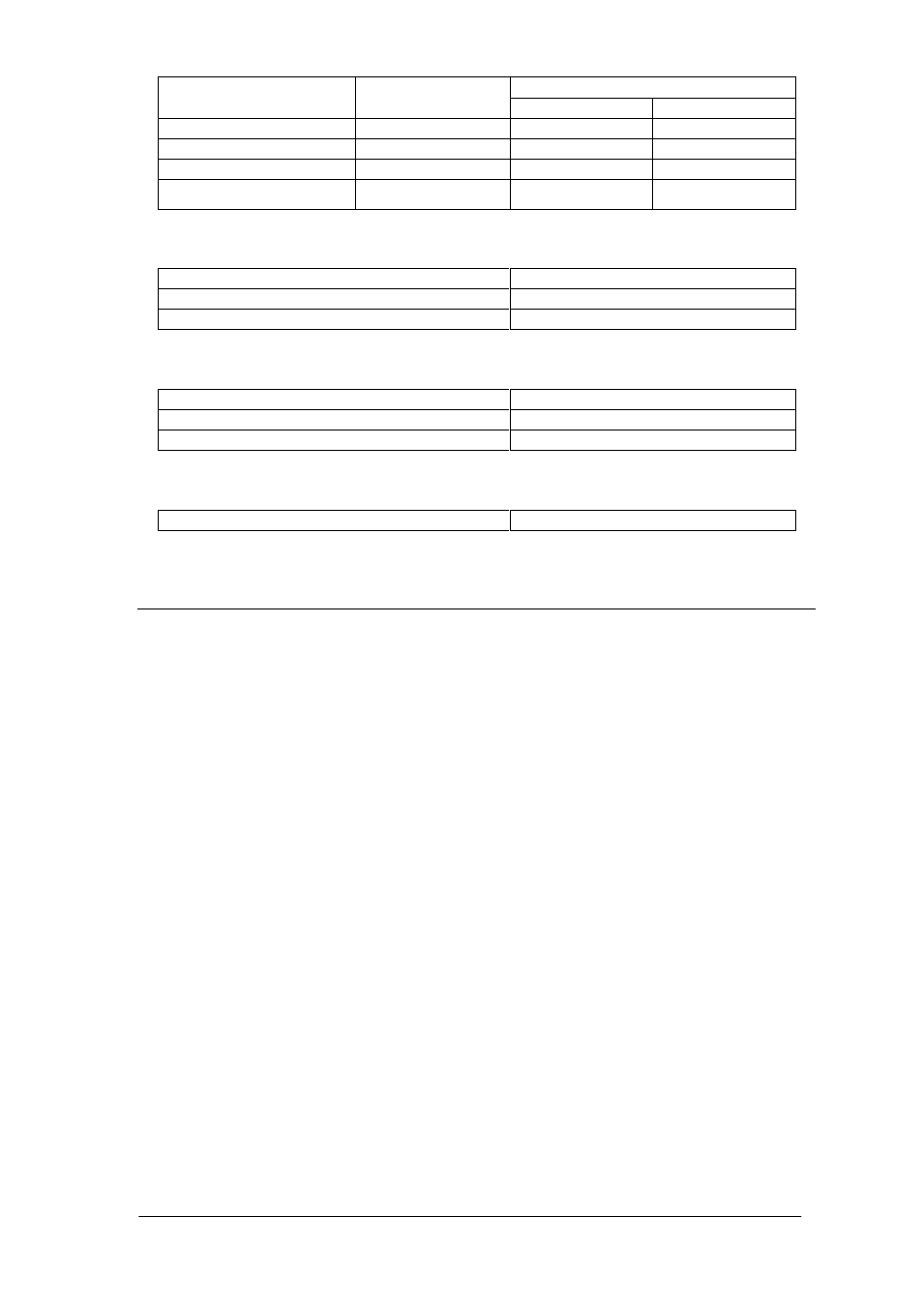

Models

Capacity (L)

Current Rating (A)

120V

230V

SBB Aqua 5 Plus

5

6

11

SBB Aqua 12 Plus

12

7

11

SBB Aqua 18 Plus

18

9

11

SBB Aqua 26 Plus

26

9

11

SUB Aqua Plus bath performance

Temperature range

5°C above ambient to 99°C

Display (also used for setting)

10.0 to 99.0°C in steps of 0.1°C

Temperature stability at 37°C

± 0.2°C

JB Aqua Plus bath performance

Temperature range

5°C above ambient to 98°C

Setting scale

10 to 98°C in 2°C graduations

Temperature stability at 37°C

± 1.0°C

SBB Aqua Plus bath performance

Temperature range

100°C only

7.0 Technical Tips

7.1

Which water should you use in your bath?

For the long-term reliability of water baths it is important to use oxygenated water that is

free from ions and minerals that can cause corrosion of stainless steel. We recommend

the use of distilled water and de-ionised water from modern ion exchange systems that

do not use salt back flushing to regenerate the ion-exchange cartridges.

Stainless steel is protected from corrosion by a layer of chromium oxide. If the layer is

damaged, oxygen present in water can reform the oxide layer. If the water is still or de-

oxygenated, and the oxide layer is damaged, ions can corrode the stainless steel tank. If

a water bath has been unused for some time, or water boiled, we recommend changing

to fresh distilled water or correct de-ionised water.

Water normally contains calcium or magnesium ions. De-ionised water has most ions

removed as indicated by its conductivity level; the purer the water the lower the

conductivity. It is important to use only de-ionised water from an ion exchange system

with replaceable cartridges. Do not use de-ionised water generated from an ion-

exchange system that incorporates a salt back-flush system to regenerate the ion-

exchange resin as this can leave sodium ions that are very corrosive to stainless steel.

7.2

How to prevent rust in water baths

Most Grant tanks, as well as immersed parts, are made from type 304 stainless steel, an

extremely versatile general purpose grade of stainless steel. It is the excellent forming

characteristic that has made this grade dominant in the manufacture of laboratory and

industrial water baths, as well as domestic sinks and saucepans. Type 304 stainless

steel is highly suitable for applications where hygiene is important; it exhibits good heat

resistance and excellent resistance to corrosion.