Electrical – FloAire Modular Packaged Unit User Manual

Page 7

7

Plumbing Connections

There is one field plumbing connection required for proper DX coil operation. This is the drain pan

located under the DX coil. Depending on the size of the unit, the coil can generate 5 gallons of water per

hour. It is imperative that the plumbing be sized accordingly. Also, it’s recommended that all plumbing

connections be sealed with Teflon tape or pipe dope.

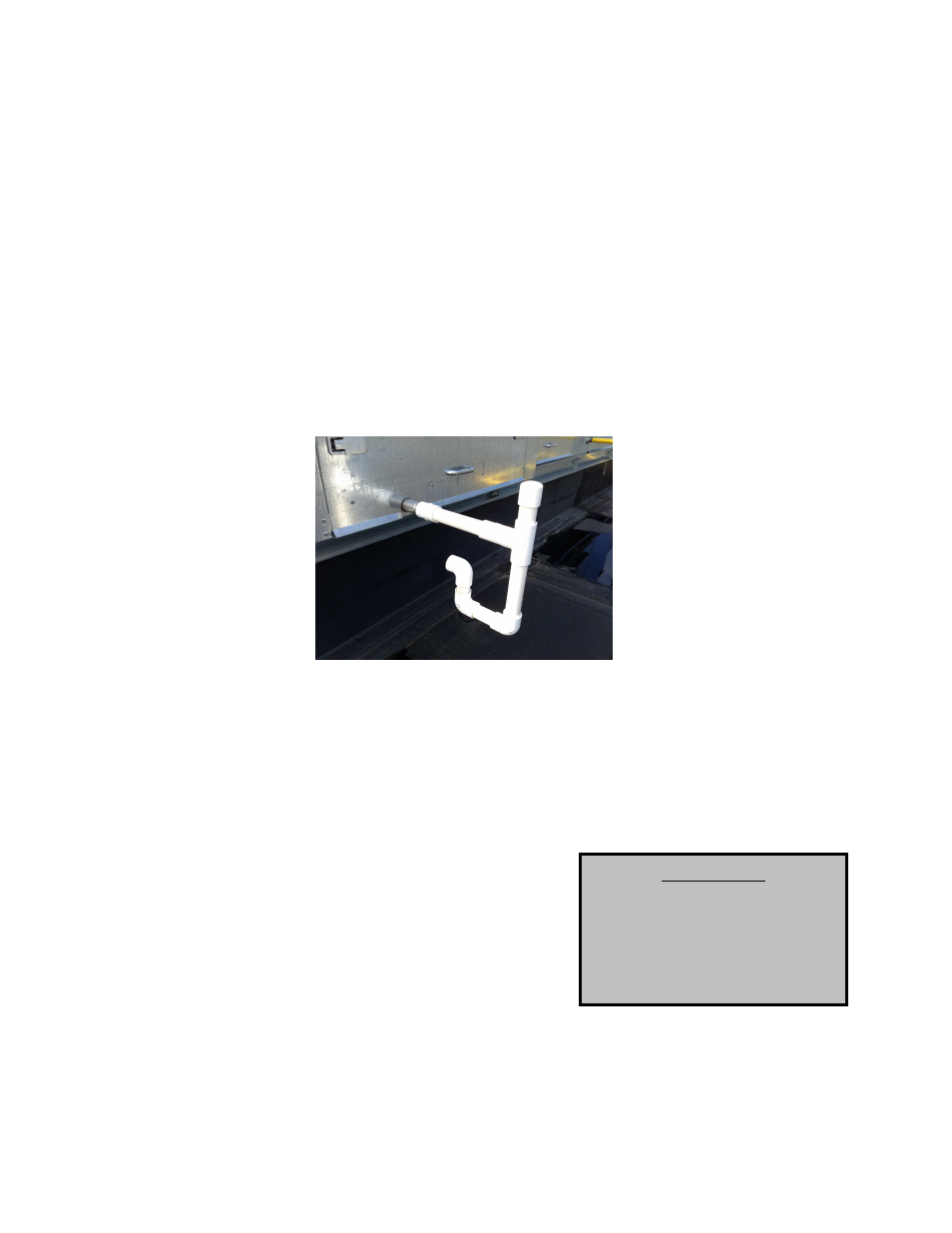

Only 1” diameter PVC Pipe and low profile couplings should be used. Additionally, the top horizontal

length on the P-Trap should be a minimum of 12”. No unions should be used. Add a clean out as shown

in the picture below.

The P-Trap drain should be attached to the end of the drain pipe on the side of the unit. The trap is

important for two reasons. First, it can be piped to drain in the most convenient area. Second, it keeps

air from being drawn through the drain hole in the side of the pan, impeding drainage.

Typical Cooling Coil Drain Trap

Gas

Refer to the Make-up air (MUA) manual that shipped with this unit for gas installation details.

Electrical

Before connecting power to this unit, read and understand the

entire section of this document. As-built wiring diagrams are

furnished with each fan by the factory and are attached to the

door of the unit.

Electrical wiring and connections should be done in accordance

with local ordinances and the National Electric Code,

ANSI/NFPA70. Be sure the voltage and phase of the power

supply and the wire amperage capacity is in accordance with the

motor nameplate. For additional safety information refer to AMCA publication 410-96, Recommended

Safety Practices for Users and Installers of Industrial and Commercial Fans.

WARNING!!

Disconnect

power

before

installing or servicing fan. High

voltage

electrical

input

is

needed for this equipment. This

work should be performed by a

qualified electrician.