Operation, Start up – FloAire Modular Packaged Unit User Manual

Page 10

10

OPERATION

Prior to starting up or operating this unit, check all fasteners for tightness. In particular, check the set

screw in the wheel hub, bearings and the fan sheaves (pulleys). With power and/or gas OFF or prior to

connecting ventilator to power, turn the fan wheel by hand to be sure it is not striking the inlet or any

obstacles. Re-center if necessary.

WARNING: GLOVES AND SAFTEY GLASSES MUST BE WORN WHEN SERVICING

REFRIGERATION EQUIPMENT.

Start Up

Special Tools Required

•

AC Voltage Meter

•

Tachometer

•

Standard Hand Tools

•

Refrigeration Gauge Set

•

Amperage Meter

•

Manometer

•

Differential Pressure Gauge

•

Thermometer

Start Up Procedure

1. Check all electrical connections for tightness and continuity.

2. Check pulley alignment and belt tension as described below.

3. Inspect the condition of the intake damper and damper linkage, if

provided.

4. Inspect the air-stream for obstructions and install intake filters if

missing.

5. Compare the supplied motor voltage with the fan’s nameplate

motor voltage. If this does not match, correct the problem.

6. Start the fan up, by turning the external MUA disconnect to the ON

position, and shut it OFF immediately to check rotation of the

wheel with the directional arrow on the blower scroll. Reversed

rotation will result in poor air performance, motor overloading and

possible burnout. For units equipped with a single-phase motor,

check the motor wiring diagram to change rotation. For 3-phase

motors, any two power leads can be interchanged to reverse motor

direction.

7. When the fan is started up, observe the operation and check for

any unusual noises.

8. Once the fan is operating properly, turn the condenser disconnect

to the ON position. If the outside air temperature is below 55°F,

the condensers should not operate for an extended period of time.

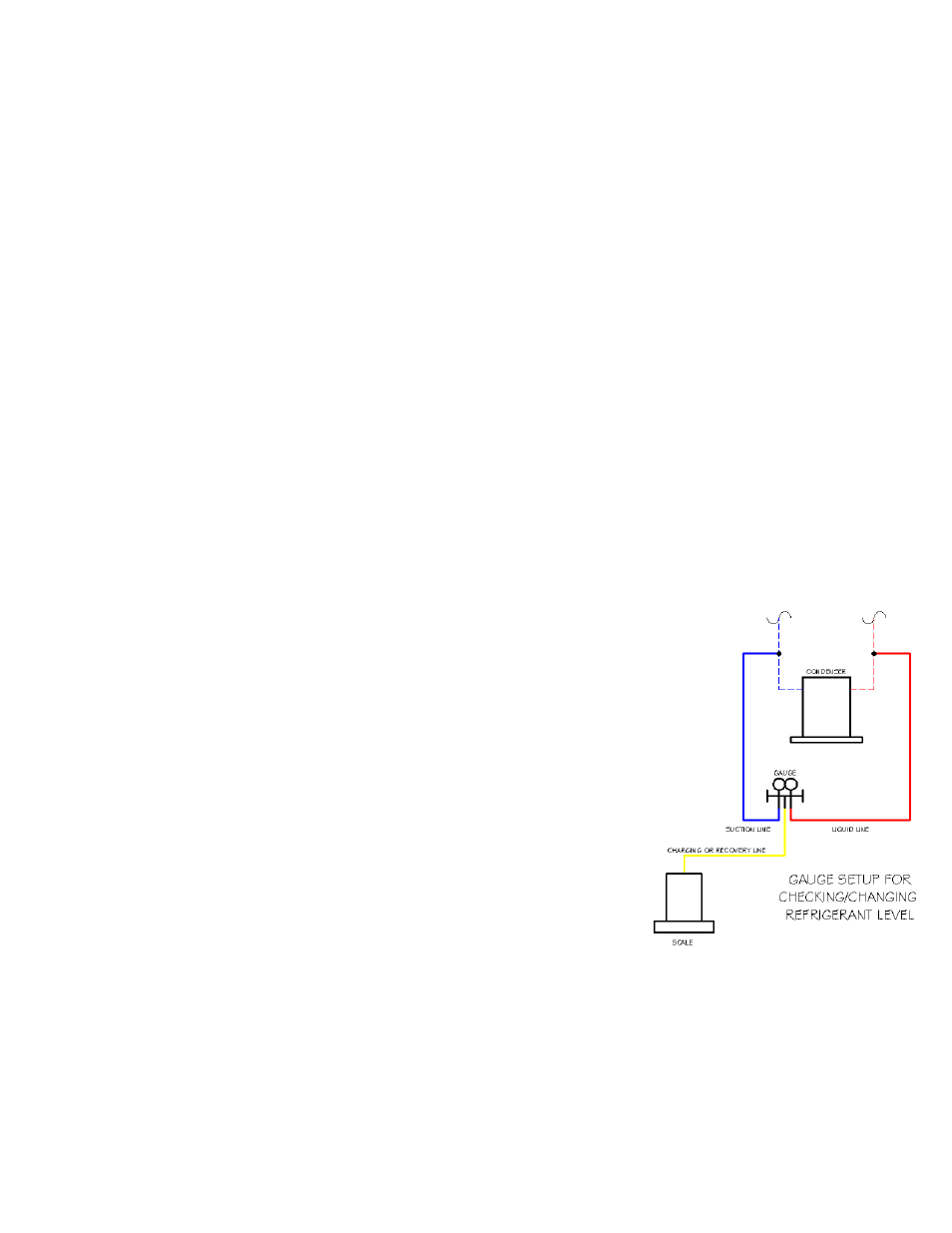

9. Connect a refrigerant gauge set as shown below to the right.

10. Turn the cooling thermostat down to energize the first condenser.

11. Let the condenser operate for about 15 minutes and check refrigerant operating temperature and

pressure. For R410-A refrigerant, the proper suction temperature is approximately 45°F and the

proper liquid temperature is approximately 100°F. Set the refrigerant level to the proper

subcooling as indicated on the condenser label. Also, adjust the TXV to 10 degrees of superheat.

12. Disconnect the gauge set and repeat these steps on the other condensers if needed. The cooling

thermostat will need to be turned down further to energize the second or third condenser.