Flintec, Troubleshooting, 7 errors – Flintec FAD-4 User Manual

Page 18

FLINTEC

Document

Date

Code

Rev.

Page

FAD - 4 DIGITAL LOADCELL JUNCTION BOX

02.05.00

FAD4_2RM

2

18 of 20

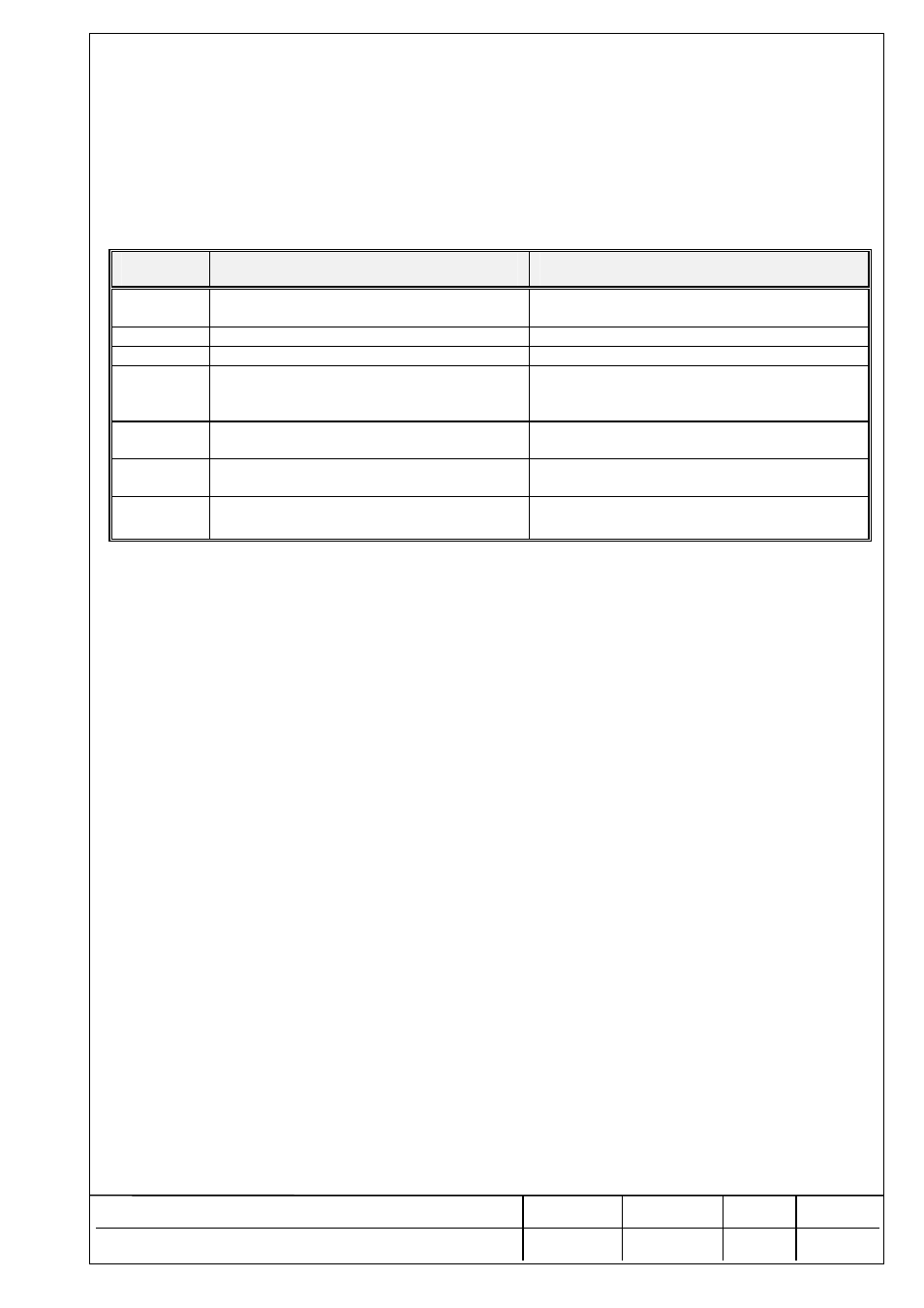

7 ERRORS

This chapter provides information on error messages and troubleshooting instuctions.

Errors may be hardware or software related. They are output in the form Error xx, where xx is the error

code. The Master computer must send ACK block to acknowledge the error.

Following is a list of errors with indication of possible causes and probable remedy.

ERROR

POSSIBLE CAUSE

ACTION TO BE TAKEN

ERR 01

System ROM. Faulty IC 2

Check solder connections or contact manufacturer

ERR 02

System RAM. Faulty IC 2

Check solder connections or contact manufacturer

ERR 04

Calibration loss or faulty EEPROM IC 1

Recalibrate or contact manufacturer

ERR 05

Mechanical failure or loadcell or A/D converter

IC 13

Check scale, loadcell cables, reset DJB, power off-

wait 5sec-power on, contact manufacturer.

ERR 15

System has been initialised due to power failure

or soft reset

Empty scale and set to Zero .

ERR 90

Not enough weight for span calibration

Recalibrate.

ERR 91

Calibration lock jumper is inserted, or software

lock is activated.

Remove calibration lock jumper, or unlock

calibration.

TROUBLESHOOTING

SYMPTOMS

ACTION TO BE TAKEN

* LED D10 does not light.

*Check the ac/dc supply. If the power is present but there are no 5VDC check fuse F13.

Replace if necessary with same type fuse only.

*FAD-4 does not

*Check communication setup (baud rate, data bits, parity, FAD address).

communicate with HOST.

Check communication cable.

Check polarity of RS485 (Refer to drawing ‘FAD-4/703.2/088’).

*Weight output from

*Decrease number of DJB (s) to be scanned at HOST.

FAD-4 is too slow.

Increase Baud Rate.

Increase number of conversions per second.

*Corner calibration

*Check number of load cells connected and setup parameters of FAD.

does not proceed.

(e.g for a weigh system with 2 load cells, set number of load cells=2

Place a test weight on each corner in turn and verify (using internal resolution corner

reading) that there is a positive change in resolution.

Use calibration weight equal to 10-30% of each load cell capacity.

Check loadcells and connector screw terminals (if not tight push with a tool from the

opposite side of the screw).

*Weight output from

*Check calibration data. Reduce external divisions or lower conversion rate

FAD-4 is not stable.

or increase digital filter, check number of load cells. Check power supply

Check load cell connection(s) and cable(s). Check input and output resistance and

resistance between any terminal and shield.

*Weight Output is not the same

*Check that the scale is mechanically OK and it is free on all sides.

on each corner.

Check load cell connection(s) and cable(s). Check input and output resistance

and resistance between any terminal and shield.

Check calibration data. Recalibrate corners with sufficient stabilization time.