Procedure for adjusting or replacing drive belt, Procedure for attaching a vacuum – EDCO 2GC-NG-11H User Manual

Page 12

E-2ECGCNG-I-0513

Printed in USA

©2013

Page 12

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com • Email: [email protected]

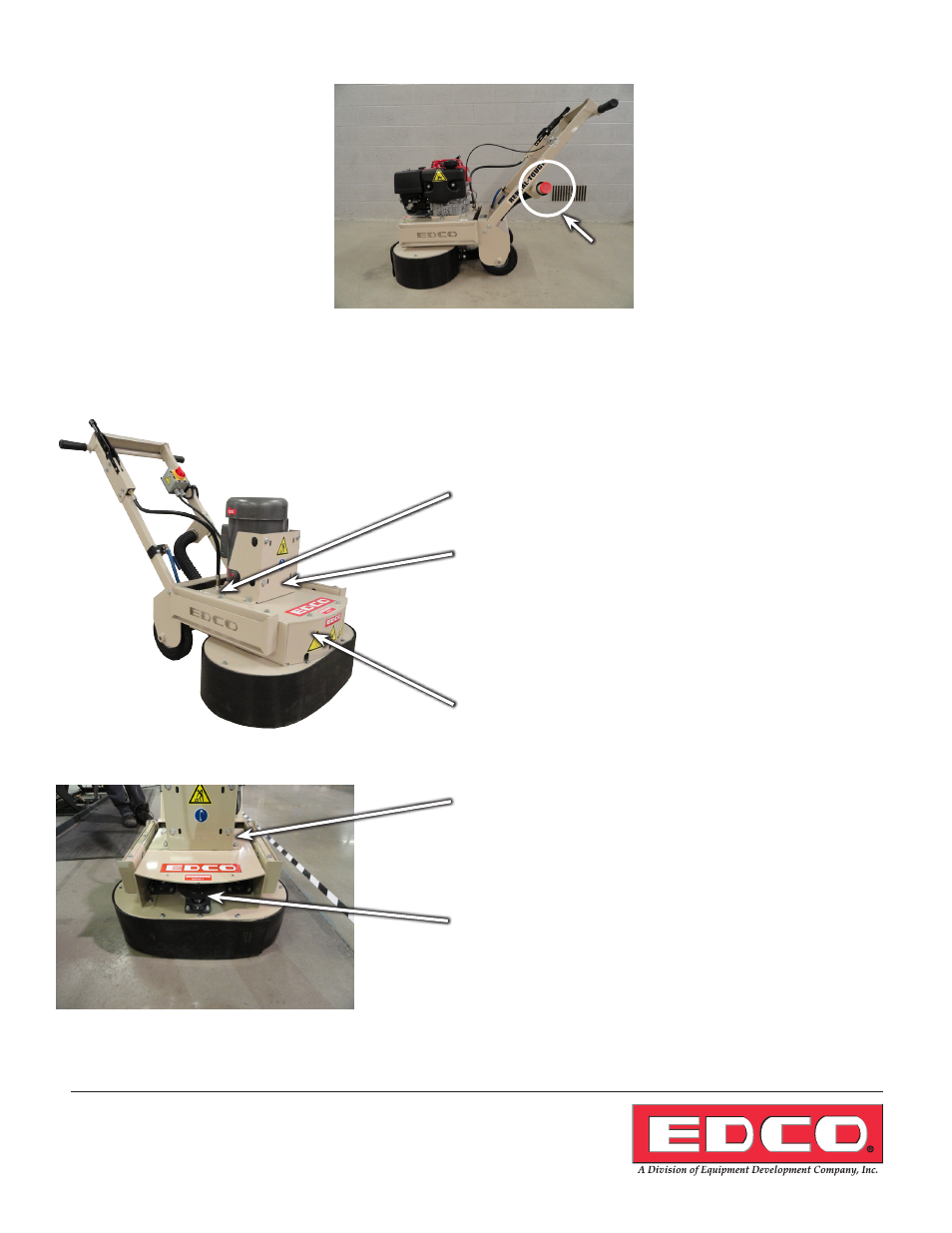

PROCEDURE FOR ADJUSTING OR REPLACING DRIVE BELT

NOTE: The following applies to all machines. They all adjust in

the same manner.

To adjust the drive belt loosen four (4) cap screws securing the

motor mount to the frame.

Slide the motor mount to the rear of the machine to increase belt

tension.

Tighten the four (4) cap screws loosened earlier maintaining

pressure on the motor mount to prevent loosening.

To replace the belt, remove the front cover by removing two (2)

cap screws on front top of the machine.

Loosen the four (4) cap screws as in the first step and slide the

motor mount all the way forward.

Tilting the machine back so handle rests on the floor and having

someone hold it down will help aid in tightening the belts.

Remove the belt from the motor and pinion shaft sheaves as

shown in the photo on the left.

Reverse the previous step to install new belt. Slide motor mount

towards the rear of the machine and adjust belt tension, tighten

all four (4) cap screws as explained above. Replace front cover

and tighten bolts.

New belts should be retensioned after grinder has been used for

4 hours.

PROCEDURE FOR ATTACHING A VACUUM

If using a vacuum for dust control attach it to the vacuum port at the rear of the machine which is on the handle as pic-

tured above, securing it with clamps. The port is circled in the above photo. The vacuum port is in the same location on

both the gas and electric models.

Vac

Port