Operating instructions, Procedure for lubricating flange bearings – EDCO 2GC-NG-11H User Manual

Page 11

E-2ECGCNG-I-0513

Printed in USA

©2013

Page 11

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com • Email: [email protected]

Operating Instructions

• BEFORE STARTING THE ENGINE OR MOTOR: Raise the front of the machine clear of the working surface.

• START ENGINE/MOTOR AND ALLOW IT TO REACH OPERATING SPEED. Position the grinder at the starting

point. Bring the engine to full speed. Lower the machine onto the slab surface. Use a slow sweeping motion from left

right and back continously, and do not force the machine into the work, the engine or motor should not strain

when grinding.

• WHEN WET GRINDING: Water is required. Attach the water hose to the water hook-up valve. Use the valve to

control the flow of water.

• FOR DRY GRINDING: Provide a respirator and dust control system.

• FOR GASOLINE MODELS: Put the engine stop switch in the “RUN” position. Consult the engine manufac-

turers operating instructions and follow the directions for starting and breaking in the engine.

• TO STOP THE MACHINE: Stop forward motion, tilt machine to raise off of floor. On gasoline models push the throt-

tle to idle. Turn ignition or power switch off and let the engine come to a complete stop. Turn off the water supply.

• WHEN MANEUVERING THE GRINDER: Tilt grinder back enough so it does not strike the slab surface. Damage to

accessories may occur with inadvertent contact with the slab.

• DO NOT FORCE GRINDER WHILE GRINDING.

• IF THE POWER SOURCE FAILS: Raise the grinder off of the floor. Disconnect the power source (i.e. the

spark plug wire on a gasoline engine). Inspect the accessories for damage. Replace damaged (or questionable)

accessories immediately.

• WHEN TRANSPORTING THE GRINDER: Disconnect the power source before lifting or removing any guards.

Remove accessories when transporting.

• WHEN HOISTING OR LIFTING A GRINDER : Always inspect frame and attaching hardware for damage

before lifting. Use proper safe hoisting and lifting techniques and hardware.

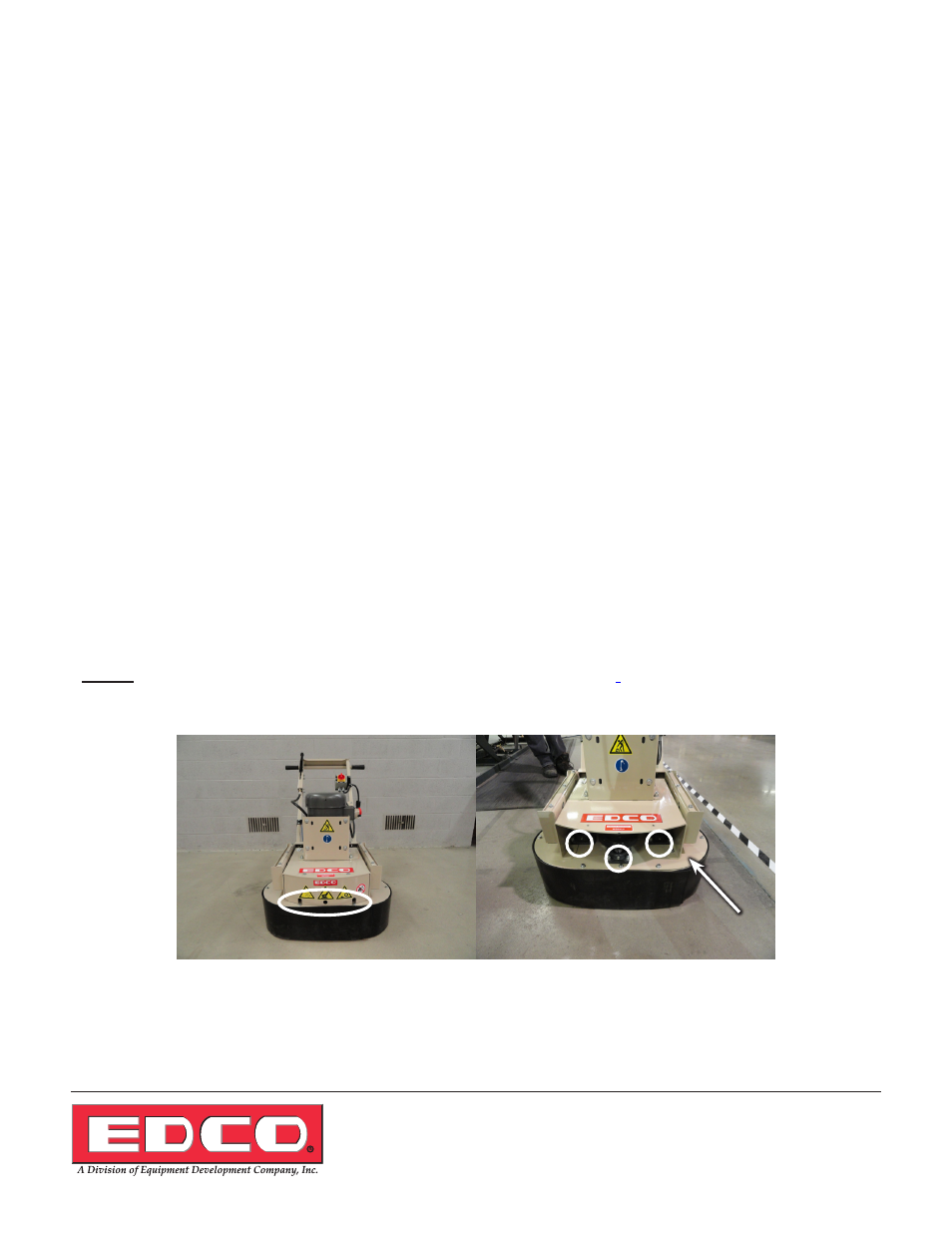

PROCEDURE FOR LUBRICATING FLANGE BEARINGS

To grease the flange bearings attach the grease gun to the grease fittings through the access holes circled in photo above

left and give only two (2) pumps on the grease gun every 50 hours of use. If excessive over lubrication is done grease will

leak onto the work surface causing possible damage and wasted cleanup time. Inspection hole on gear case is located

towards rear center of machine on top of gear case.

Gear

case