Operating instructions – EDCO 2GC-NG-11H User Manual

Page 10

E-2ECGCNG-I-0513

Printed in USA

©2013

Page 10

100 Thomas Johnson Drive, Frederick, MD 21702-4600 USA

Phone (301) 663-1600 • 1-800-638-3326

Fax (301) 663-1607 • 1-800-447-3326

Website: www.edcoinc.com • Email: [email protected]

• Read and understand all operating instructions before operating this equipment. Death

or serious injury can result if this machine is used improperly.

• Concrete grinders are designed to be used to grind flat horizontal concrete slabs using EDCO

approved accessories.

• The machines are equipped with gasoline/propane engines and electric motors.

• They are designed to be controlled by a single operator from a position at the rear of the machine.

• When operating equipment maintain a safe distance from other personnel in the area.

Be sure to read the complete instructions supplied with your machine.

IMPORTANT: Perform Pre-Start Check.

• Visually inspect the equipment for wear or damage.

• Be sure all guards are in place and functioning properly. Do not operate unless all guards are in place and secure.

• Perform all daily maintenance.

• Check to be sure water tubes are functioning properly if performing wet-grinding operations.

• Inspect accessories - Be sure the correct accessory is installed properly on the machine, mounting arrangement and

its intended use.

• Check accessories for damage (see figure 6, below), the type of wear or damage will vary with the type if acces-

sory.

• Inspect work area to determine the presence and location of deck inserts, pipes, columns and objects protruding from

the slab surface so that they may be avoided during the grinding operation.

• FOR WET GRINDING: Attach the water supply. A flow rate of approximately 1/2 gallon per minute is recommend-

ed.

Operating Instructions

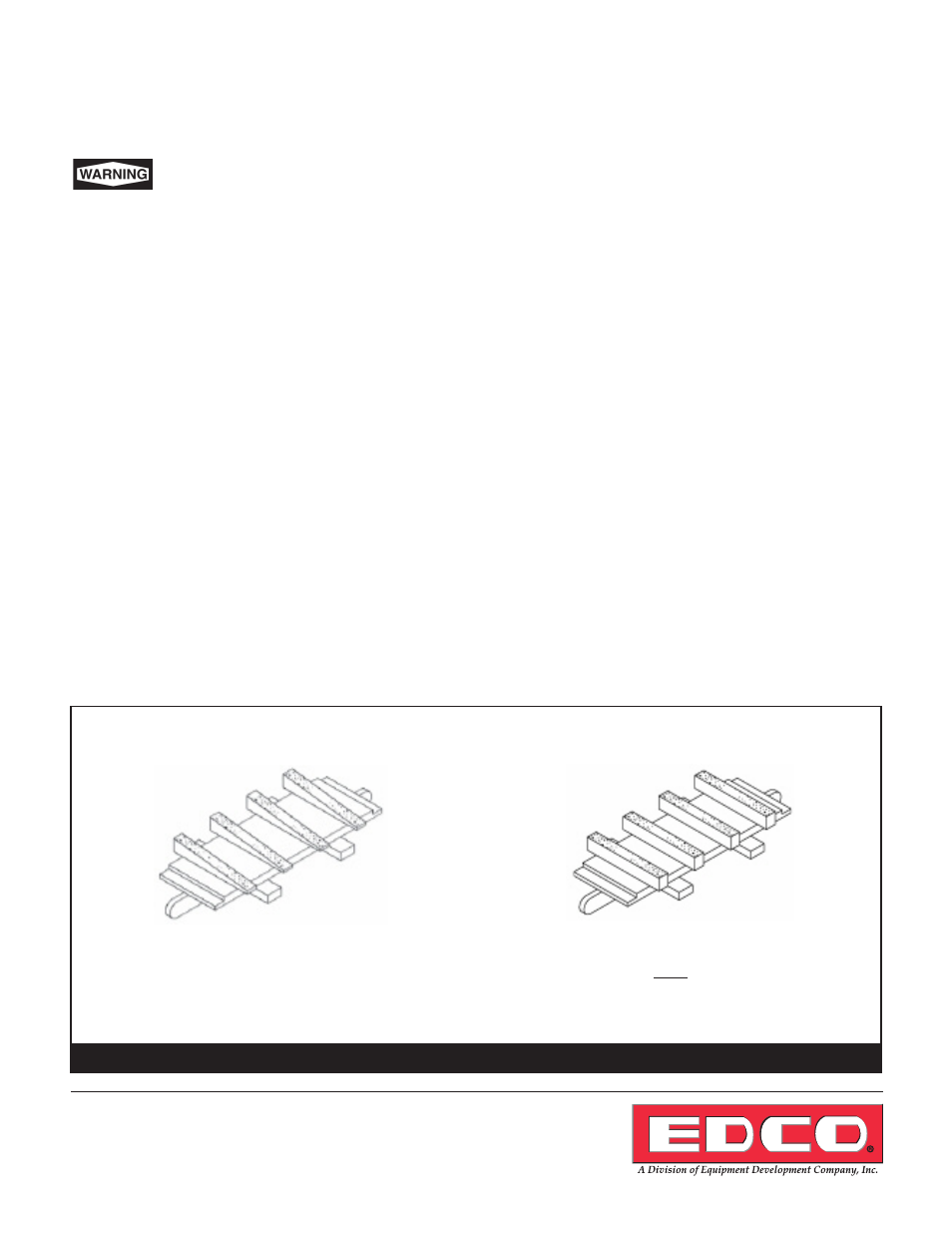

Figure 6

EXAMPLE OF SEVERELY WORN

DYMA-SERT

EXAMPLE OF AN EVENLY WORN

DYMA-SERT

The above in an example of a DYMA-SERT that has

not been rotated after every four hours of use. To get

maximum life out of a DYMA-SERT they should be

rotated 180º every four hours of use.

The above in an example of a DYMA-SERT that has

been rotated after every four hours of use, as you

can see the wear is even across all segments.