8installing the dle-170 on your airplane – DLE 170 User Manual

Page 8

8

Installing the DLE-170 on Your Airplane

Note: The DLE-170 must be installed on at least a 3/8" [9.5mm]

fi rewall. The fi rewall must be securely glued to the airplane. Use

triangle stock and pin the fi rewall with hardwood dowels to

reinforce the fi rewall glue joints. Never install the DLE-170 onto

a fi rewall thinner than specifi ed because it may fail due to the

power of the engine.

Note: The distance from the fi rewall to the propeller washer is

8.34" [212mm].

1. Use the supplied template (on the back cover of this manual) to

drill the engine mounting bolt holes.

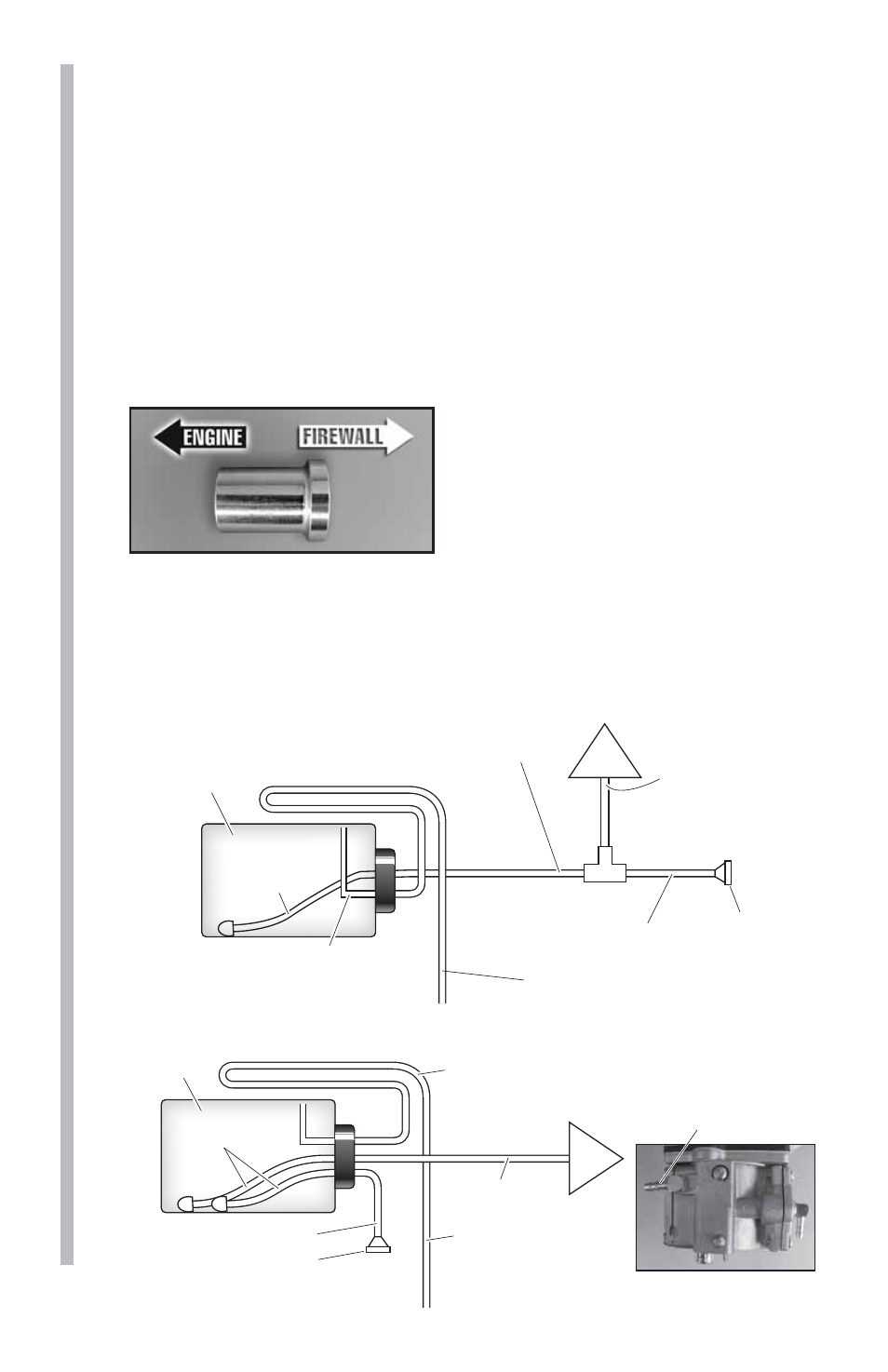

2. Install (4) 6mm blind nuts or tee

nuts (not included) into the back

side (non-engine side) of the fi rewall.

Install the engine to the fi rewall

using (4) 6x45mm SHCS with 6mm

lock washers and fl at washers (not

included) with the included standoffs. Use some threadlocking

compound, such as Great Planes

®

Pro

™

Threadlocker (GPMR6060)

on the screws where the threads enter the blind nuts.

3. Install the fuel tank in the airframe. Use only gasoline-safe fuel

lines and a gasoline safe stopper.

Drain/Vent Pressure Relief Line

Route to top-front of fuel tank interior,

to prevent siphoning.

T-Fitting

Carb

Clunk Line

Fuel Tank

Filler Cap

or Plug

Supply Line

to T-Fitting

Make connection line

between T-Fitting and

Carburetor as short

as possible.

Fuel fill line

This line must be extended

to exit the bottom of the aircraft.

2-LINE SET UP

Drain/Vent Pressure Relief Line

Route to top-front of fuel tank

interior, to prevent siphoning.

Carb

Clunk Lines

Fuel Tank

Carburetor Fuel Inlet

Plug

Supply Line

to Carburetor

Fuel fill line

This line must be

extended to exit the

bottom of the aircraft.

3-LINE SET UP