Adjustment of the engine, Engine functions & adjustments – DLE 170 User Manual

Page 11

11

5. Mark the location of

one of the outer holes on

the propeller. Use a GPM

Dead Center Hole Locator

(GPMR8130) to center and

start the hole.

6. Remove the propeller

from the engine and drill

the outer hole on the

drill press using a #35

(.110"/2.81mm) drill bit as

a pilot hole. Next use a

1/4" (6.28mm) drill bit to

fi nish the hole. In order to

achieve a clean fi nish on

both sides of the propeller

drill only half way through

the propeller with the fi nishing drill bit. Then fl ip the propeller over

and drill completely through the hole.

7. Use one of the 655mm SHCS with 6mm lock washers and fl at

washers to align the propeller washer on the propeller and use the

Dead Center Hole Locator to mark the position of the remaining holes.

8. Drill the remaining fi ve holes in the propeller using the same

technique on step 6.

9. Mount the propeller to the engine using the 655mm SHCS with

6mm lock washers and fl at washers. Be sure to use threadlocker.

Adjustment of the Engine

Each DLE-170 has been factory preset. However, higher elevations will

infl uence the performance of the carburetor. To obtain optimum output

of the engine slight adjustment of the carburetor may be necessary.

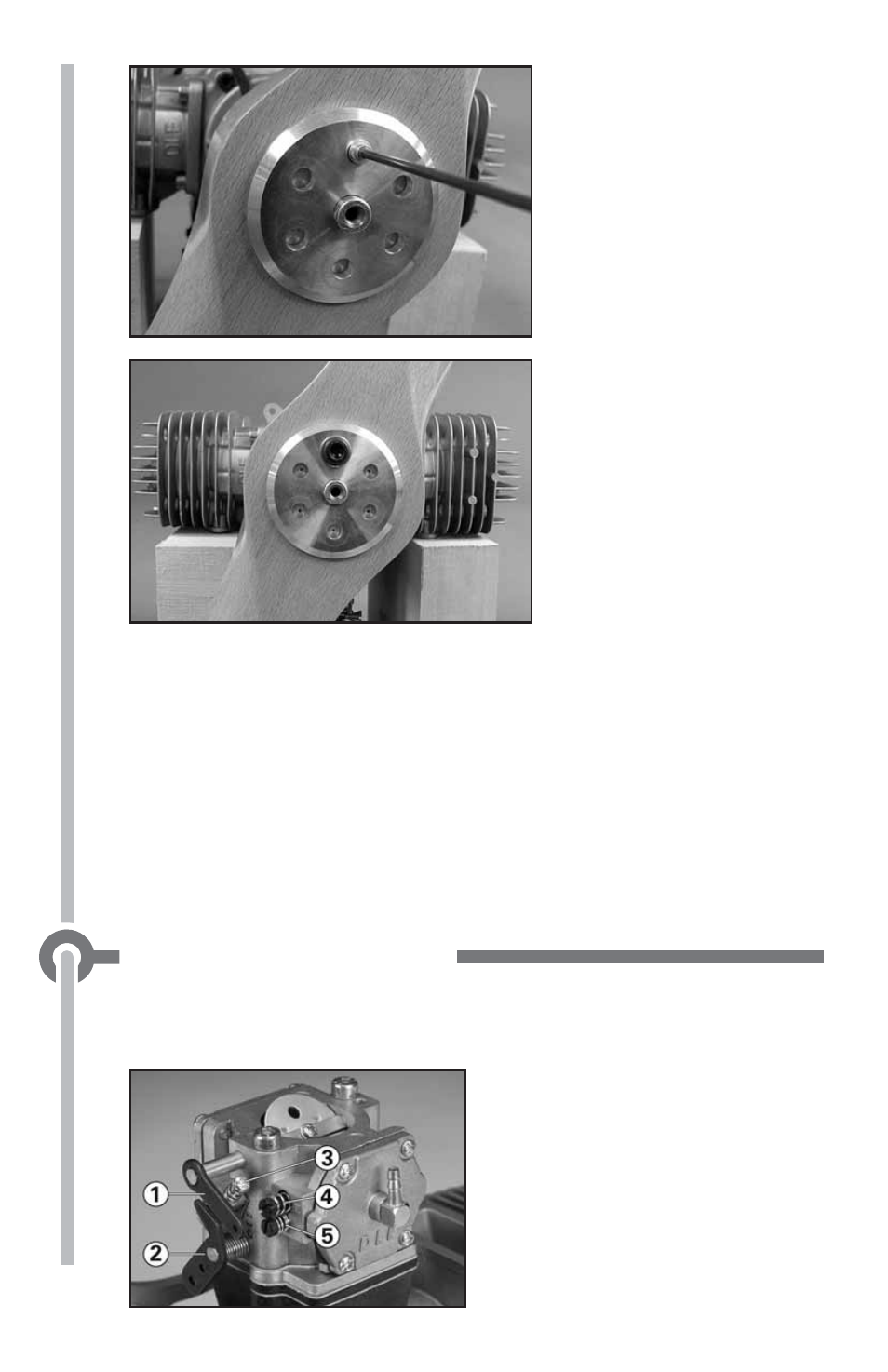

Engine Functions & Adjustments

1. Choke Control (the choke control should

be used when the engine is cold)

2. Throttle

3. Idle Adjustment Screw (adjust the

idle speed)

4. (H) High-speed Needle (adjusts the

fuel/air mixture at high speeds)

5. (L) Low-speed Needles(adjusts the

fuel/air mixture at low speeds)