Common mistakes – COMP Cams 4943 Camshaft Degree Kit for Ford 5.0L 4V User Manual

Page 4

COMP Cams

®

3406 Democrat Rd.

Memphis, TN 38118

Phone: (901) 795-2400 Fax: (901) 366-1807

www.compcams.com

Part #COMP4-170

Revised 6/28/13

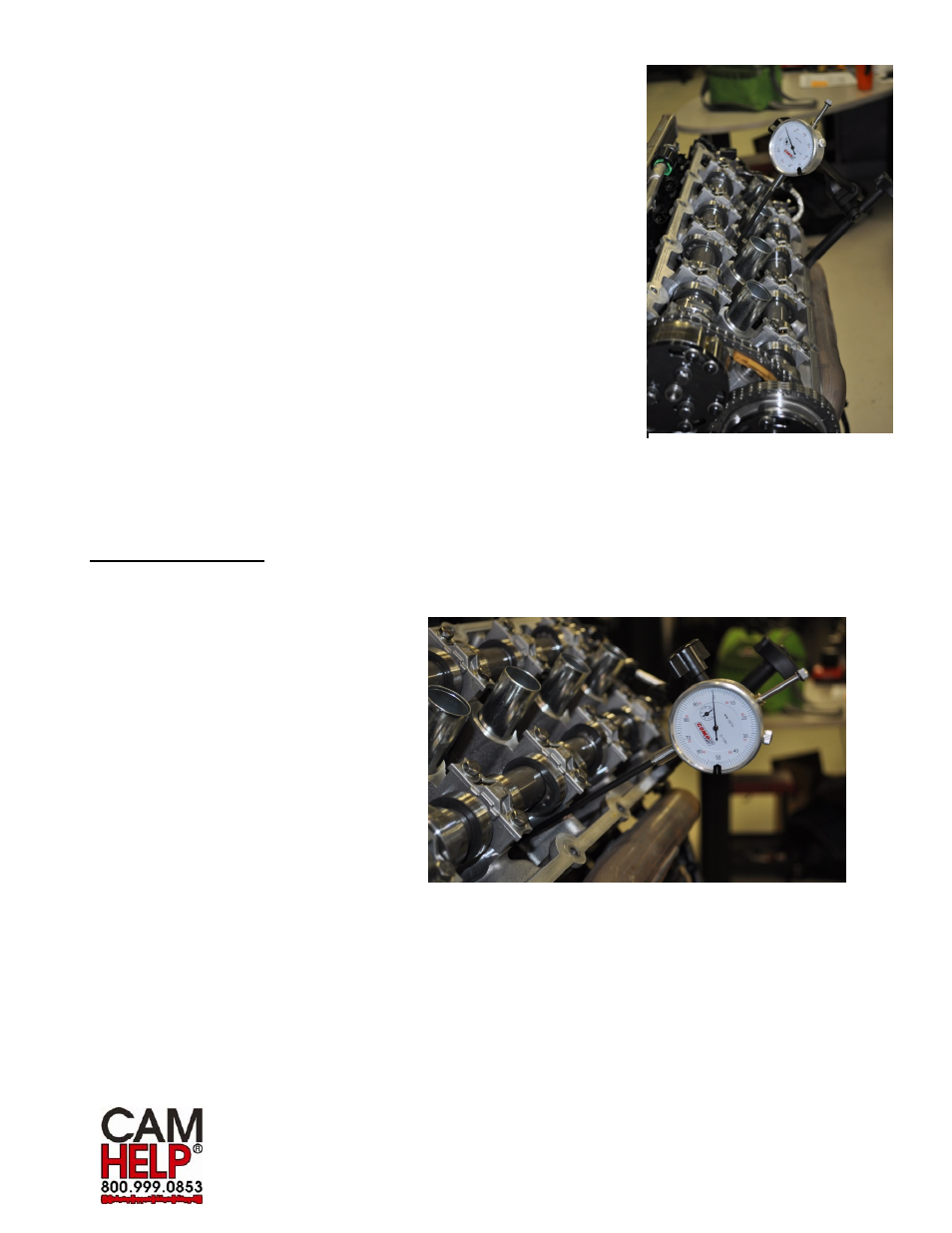

14.

Now move the dial indicator to the Exhaust cam and repeat steps 8

through 13. When completed with both cams on Cylinder 1,

reposition the dial indicator on the Intake Cam of Cylinder 6

repeating steps 8 through 13 for the intake and exhaust cams.

In the event that your camshafts did not degree in as per the

manufacturer’s specs, it will be necessary to either advance (move the

cam ahead) or retard (move the cam back) the cam to meet the

suggested intake centerline.

Note: When degreeing a cam, remember to look at the degree

wheel as a full 360˚, no matter how the degree wheel you are using

is marked. Many degree wheels are marked in 90° or 180°

increments. On wheels that are marked in 90° increments, keep in

mind that you must continue to count the number of degrees on

past 90°. Be sure all readings are taken from Top Dead Center.

Common Mistakes

Note: To prevent broken or damaged valve train components, please read and follow these instructions

completely.

COMP Cams

®

strongly recommends

replacing valve springs on any engine

with 60,000 miles or more. Stock

(OEM) springs may be retained in our

NSR (No Spring Required)

Camshafts.

If you do not use enough seat pressure,

valve float will occur, causing damage

to the entire valve train and the engine

will not turn high enough RPM. If the

open spring pressure is excessive,

worn lobes will be the result. Please

refer to your camshaft spec card or

COMP Cams

®

Master Reference Catalog to determine the valve spring needed for your application.

Always use plenty of cam lube on the lobes.

Never continue cranking the engine if it doesn’t start immediately.

Cylinder 6 Exhaust

Cylinder 6 Intake