COMP Cams Elite Race Lifters User Manual

Page 3

3

COMP Cams®

3406 Democrat Rd.

Memphis, TN 38118

Phone: (901) 795-2400 Fax: (901) 366-1807

www.compcams.com

Part #COMP4-130

Revised 1/6/10

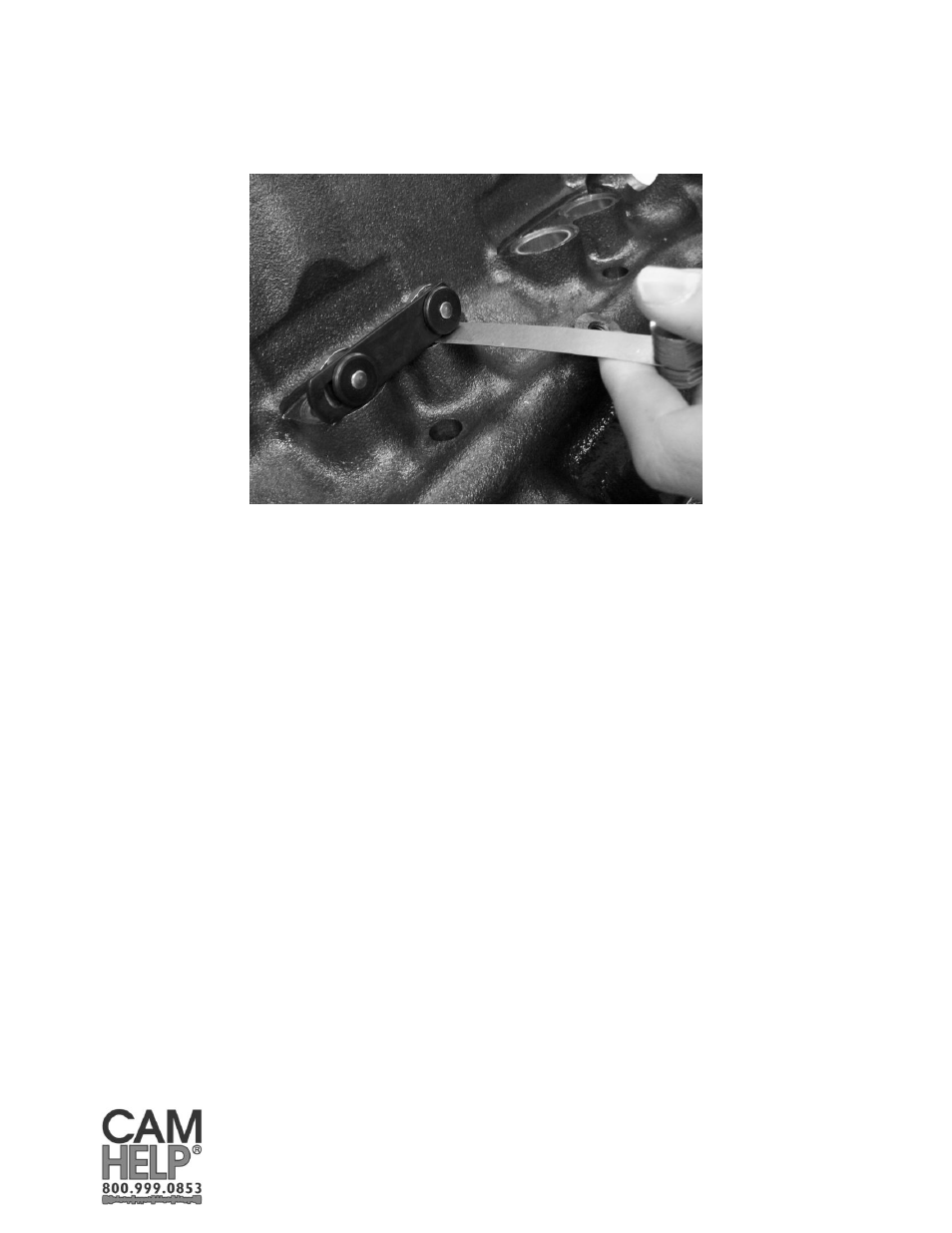

4. Now while the lifter is on the base circle of the camshaft verify that the link bar or button has

0.030" -0.035" clearance to the block as shown below.

Note: Link bar must maintain this

clearance throughout the entire lift cycle.

5. Verify that the lifters will not contact a cam journal or lobe from the side. Also, be sure that the

lifter does not contact the cam in any other way than intended.

6. While installing a pushrod and rocker assembly on one valve with the cam on the base circle,

be sure that the pushrod is correctly seated in the pushrod sockets in the rocker and lifter and

that the pushrod has no contact with any other parts, then set lash.

Before rotating the engine for a second time, verify that there is no initial contact of the

pushrod to the lifter, block, or head.

7. Now rotate the engine while checking to ensure that the link bar does not bind at any point in

the lift range. Also, verify that there is no contact of the pushrod to the lifter, block, and head,

and be sure that there is no contact of the lifter to the head or block throughout the lift range.

Be sure that all parts have 0.030" or more clearance throughout the lift range.

8. While at max lift and on the base circle, verify that the oil band or cutouts on the side of the

lifter do not extrude out of the lifter bore of the block as seen on the next page and are at least

0.050" below the exposure from the bore.