Carl Goldberg GBGA1040 User Manual

Page 13

13

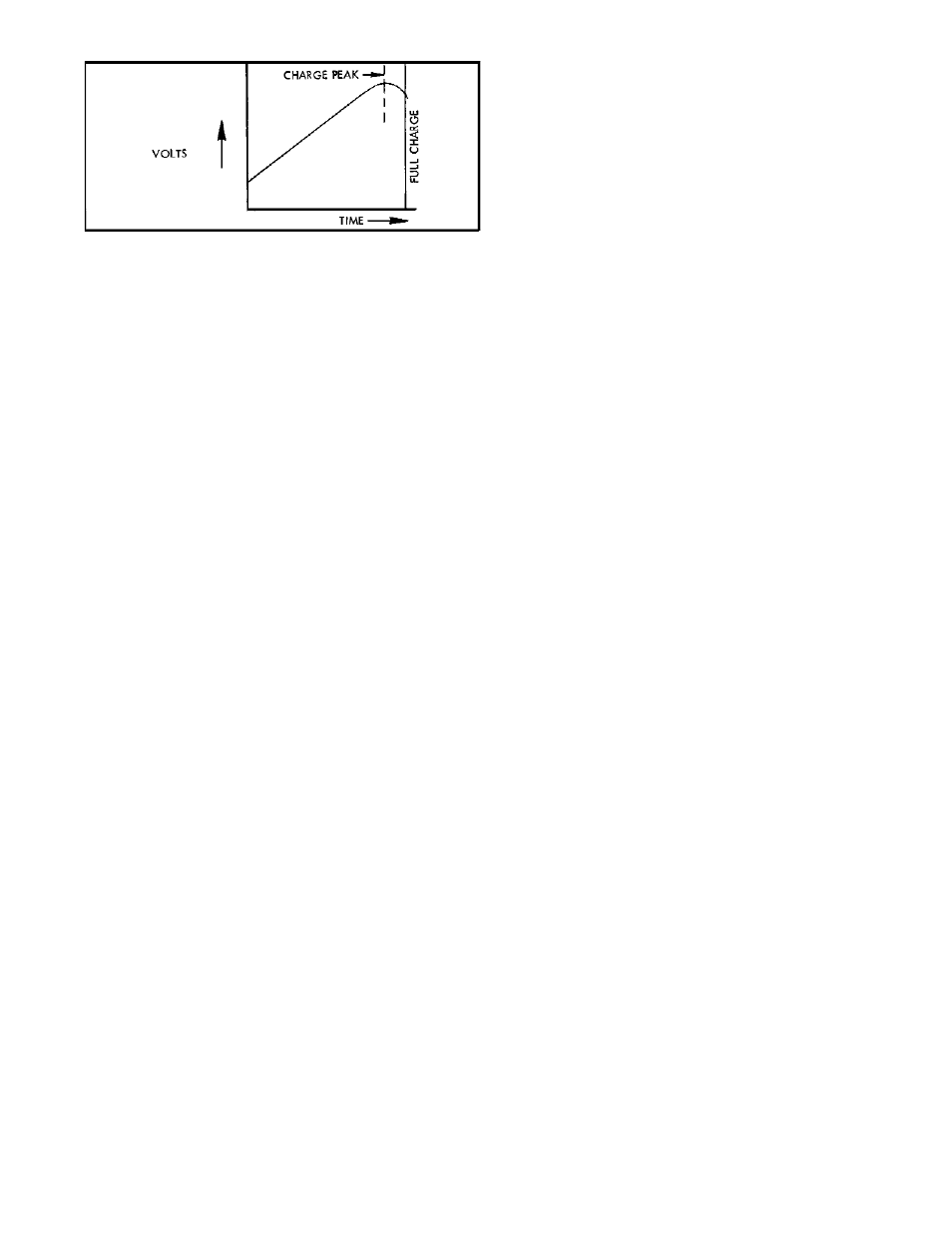

Automatic Charger's. DELTA or PEAK DETECTION

CHARGER'S are excellent methods of charging a bat-

tery, as one simply connects the charger, pushes the

start button, and waits. Within approximately 15-30

minutes, the battery may be disconnected and used.

It is still a good idea to monitor the battery temperature

(by lightly touching) every minute or so after 10 min-

utes of charging. If you suspect the battery is over-

charging, STOP IMMEDIATELY!

TEMPERATURE SENSITIVE (THERMAL)CHARG-

ER'S also work well, although they are more expen-

sive the other charges described. The thermal charger

charges a battery pack in approximately 15-20 and it

doesn’t matter how full the pack is charging begins.

This charger “senses” when the battery temperature

signals a full charge and automatically stops charging.

However, the battery must be absolutely cool when

charging begins, or the charger will cut off premature-

ly.

Follow the manufacturer’s instructions carefully

when using any type of charger.

BATTERY EQUALIZATION

Any battery that hasn’t been used for a week or more

should be equalized for best performance. This is

done by charging the battery for 10-20 minutes at the

indicated rate and then giving the battery a trickle

charge for three to four hours. Refer to the charger

instructions for the recommended trickle charge tech-

nique. Equalizing the battery will assure top perform-

ance every time.

HOW MANY BATTERIES ARE NEEDED?

To get in the most flying at each session, we suggest

you purchase three battery packs. While one pack is

cooling and waiting to be charged, a second pack can

be on the charger, and the third pack can be in the

plane and ready to fly. With only one battery pack,

there may be up to a 40-minute wait between flights.

“TREAT YOUR RADIO RIGHT AND IT WILL DO

THE SAME FOR YOU!” by Hal deBolt

Today's RC systems are very well engineered and

constructed. However, they will remain only as good

as the way in which they are USED. Always follow the

rules of proper usage and all manufacturer's instruc-

tions for your particular piece of equipment.

TRANSMITTERS: Keep your transmitter clean and

free from fuel residue and dirt. Battery condition and

RF output should be monitored, and the system

should be aligned and tuned annually. Do not trans-

port under vibration (such as on the floor of a car) with-

out cushioning.

RECEIVERS: Receivers must be vibration free. When

installing in the aircraft, wrap them in a minimum of ¼"

soft foam rubber (not plastic foam). Keep well clear of

all cables and batteries. Tune annually (or as recom-

mended by the manufacturer), as indicated below

under "Check-Ups."

SERVOS: Servos are vibration prone. Be sure to

mount them with grommet shock mounts in servo trays

which are also shock mounted. Also be sure to keep

them clean. If the neutral position "drifts," this is a sign

of change which should not be ignored; find out WHY

before flying again.

BATTERIES: Nicads also can suffer from vibration, so

they too should be wrapped in soft foam rubber before

installing. Check their condition periodically by meas-

uring the voltage with a volt meter or battery tester.

Charge the batteries before EVERY flying session.

When not used for a period of time (such as during the

winter months) the batteries should be charged every

30 days. Never store batteries in a discharged condi-

tion.

PUSHRODS: Obviously, pushrods should be installed

to operate freely, so that they place no load on the

servo. Using a servo's power to move a tight rod or

heavy surface by force increases the battery drain,

shortens the electronic life, and can cause neutralizing

problems. In addition, it is important the pushrods do

not flex or vibrate. Any vibration is transferred directly

to the servo, and its gear, motor, and pot. To avoid flex-

ing and vibration, use guides and fairleads on the rods.

CONNECTORS: In using connectors, never pull on

the wires to disconnect; grasp the plugs instead.

Clean them by dunking in a solvent, such as dope thin-

ner. Tape the connectors together when installing and

make sure there is no strain on the cables.

CHECK-UPS: A full check-up by the factory or an

authorized service center should be done AT LEAST

ONCE A YEAR, as well as any time something unusu-

al occurs during usage. A malfunction or "glitch" is the

first sign of an impending failure; it should not be

ignored. The checkup should include tuning and align-

ment of the system, as well as battery testing.