Installation – AXEON Burkert-Series User Manual

Page 4

12

6.6. Rating plate (Example)

0290 A 20,0 FKM VA

Made in Germany

00153212

W1Y LU

230 V 50 Hz 16 W

G 3/4 P

N 0 - 16 bar

Type

Operating

prinziple

Orifice

Seal material

Housing material

Identification

number

Manufacturer code

Voltage, Frequency, Power

consumption

Port connection, Nominal

pressure

english

13

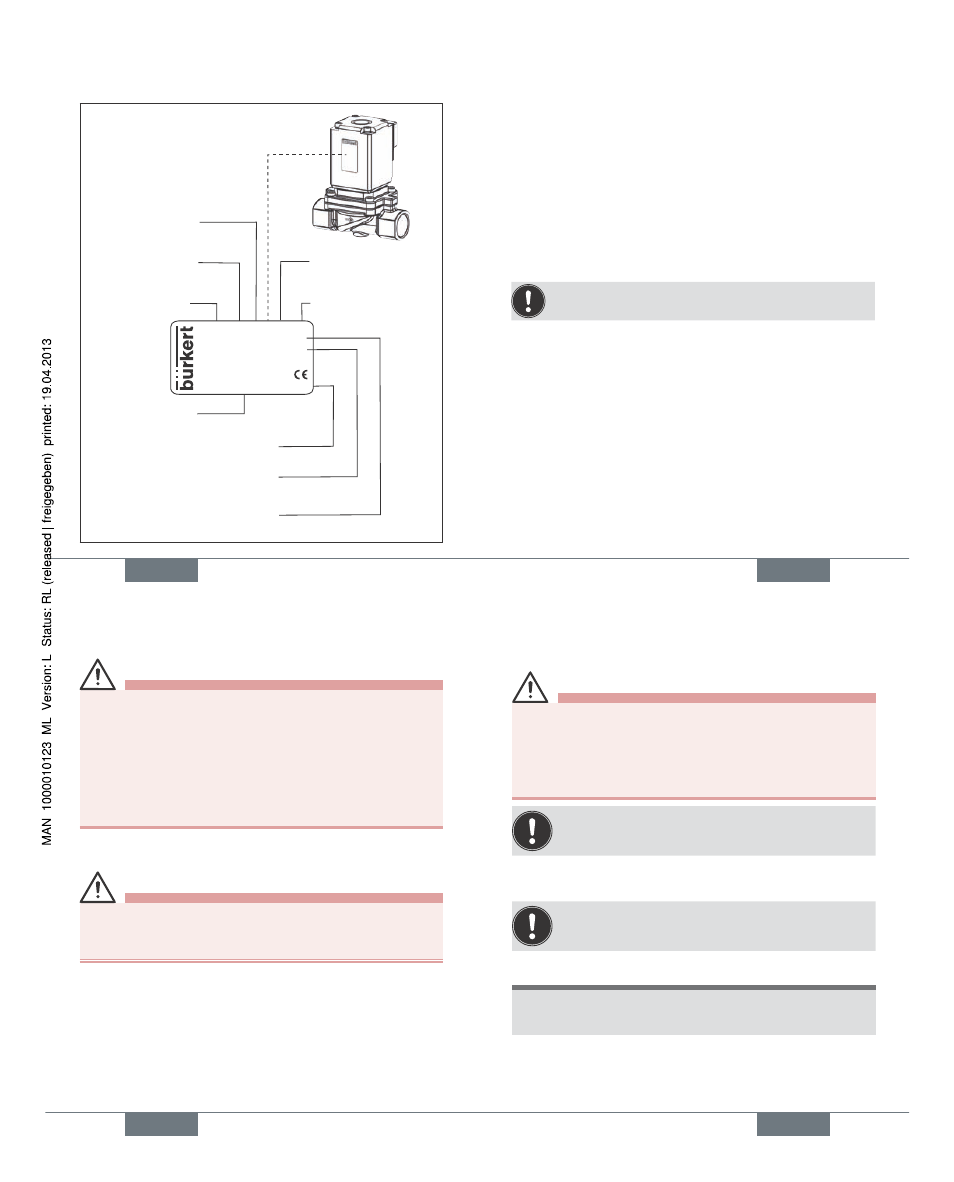

6.7. Electrical data

Connections:

DIN EN 175301-803 Form A for

device socket Type 2508

Power supply:

24 V DC,

max. residual ripple 10 %,

24 V / 50 Hz, 110 V / 50 Hz,

230 V / 50 Hz

Voltage tolerance:

± 10 %

Nominal operating mode: long-term operation, ED 100%

Note the information specified on the label for

voltage, type of current, and pressure.

english

14

7. INSTALLATION

WARNING!

Risk of injury from improper installation!

• Installation may be carried out by authorized technicians

only and with the appropriate tools!

Risk of injury from unintentional activation of the

system and an uncontrolled restart!

• Secure system from unintentional activation.

• Following installation, ensure a controlled restart.

7.1. Fluid installation

DANGER!

Risk of injury from high pressure in the equipment!

• Before loosening the lines and valves, turn off the pres-

sure and vent the lines.

Installation position:

Installation can be in any position.

Preferably: Actuator upright.

Procedure:

→

Before installation, clean any possible dirt off the

pipelines.

english

15

→

If required, install a dirt trap to prevent malfunctions.

Mesh size: 0.2 ... 0.4 mm

WARNING!

Risk of short-circuit or escape of media through

leaking screw joints.

• Ensure seals are seated correctly!

• Carefully screw together coil and device socket or valve

and pipelines!

Observe direction of flow of the valve:

1 → 2 (P → A).

→

Seal the pipe connection with PTFE tape.

The PTFE tape must not get into the device.

NOTE!

Caution risk of breakage!

• Do not use the coil as a lifting arm.

→

Hold the device with a suitable tool (Open-end wrench)

on the housing and screw into the pipeline

english

Type 0290