English – ALTANA Byko-Cut Universal Short Instructions User Manual

Page 3

269 020 584 E 0806

Additives & Instruments

A member of

Measure what you see.

BYK-Gardner GmbH · Lausitzer Strasse 8 · 82538 Geretsried · Germany · Tel. +49-8171-3493-0 · Fax +49-8171-3493-140 · www.byk.com/instruments

ENGLISH

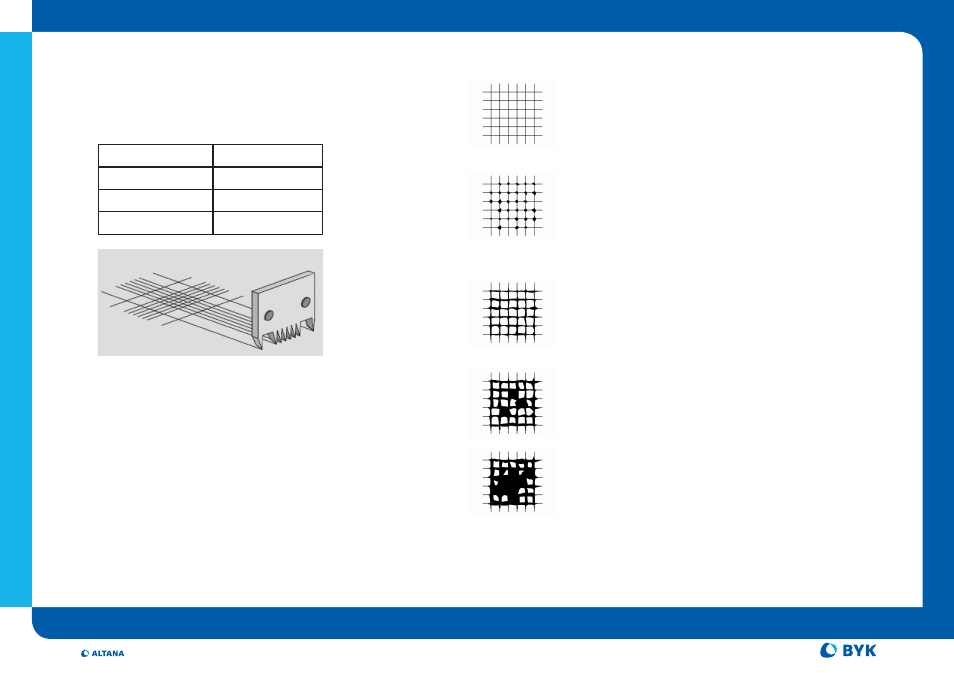

How to perform the Cross-Cut Test

How to analyze the Cross-Cut Test

•

Select the appropriate cross-cut tool based on the coating

film thickness ( see table )

•

Make a lattice pattern in the film with appropriate tool,

cutting to the substrate

•

Brush in diagonal direction 5 times each, using a brush

pen or tape and remove with tape

•

Examine the grid area using an illuminated magnifier

ISO Class: 0 / ASTM Class: 5B

•

Edges of cut are completely smooth

•

None of the squares of the lattice is

detached

ISO Class: 1 / ASTM Class: 4B

•

Detachment of small flakes at the

intersection of the cuts

•

Max. 5 % of the cross cut area is

affected

ISO Class: 2 / ASTM Class: 3B

•

Flaked along the edges and /or

intersection of the cuts

•

Affected cross-cut area: 5% - 15%

ISO Class: 3 / ASTM Class: 2B

•

Squares are partly / wholly damaged

•

Affected cross-cut area: 15% - 35 %

ISO Class: 4 / ASTM Class: 1B

•

Squares partly / wholly detached

•

Affected cross-cut area: 35% - 65 %

ISO Class: 5 / ASTM Class: 0B

•

Any flaking worse than ISO 4 or ASTM 1B

•

Affected cross-cut area > 65%

Film Thickness

Cutter Spacing

0 – 60 µm

1 mm

60 – 120 µm

2 mm

> 120 µm

3 mm