Vii. troubleshooting – Kistler-Morse KM Load Stand II User Manual

Page 25

21

www.kistlermorse.com

97-1100-01 Rev. H

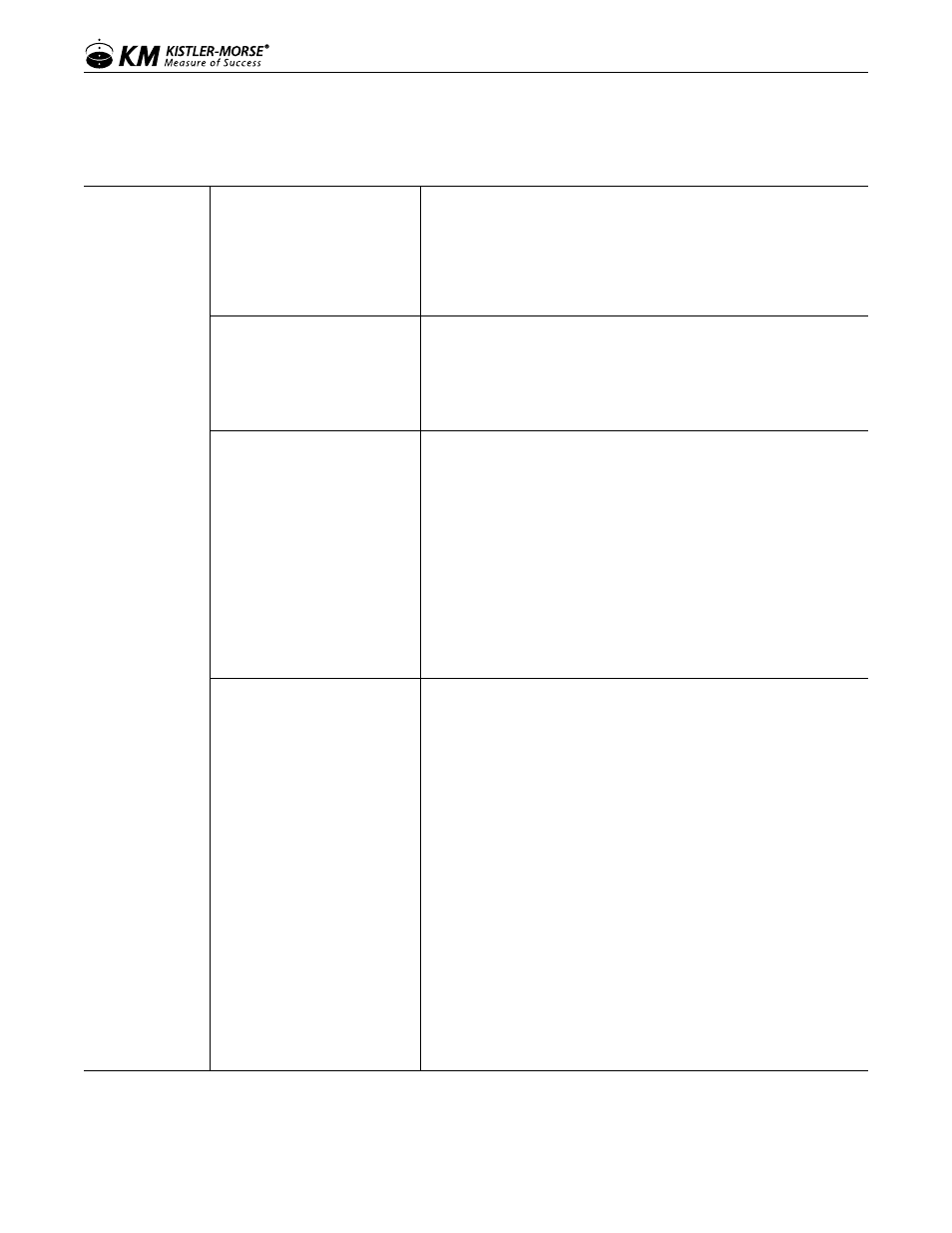

vII. TrOubLESHOOTINg

SYMPTOM

POSSIBLE CAUSE

SOLUTION

Small Amplitude

Changes or Erratic

Fluctuations in

Display Readings

Fluctuations can be caused

by small amplitude drift or

oscillation, with peak-to-peak

disturbance of 0.1% to 0.5% of

full scale, is normal.

Problem likely to be noticed

shortly after initial installation.

Reduce drift or oscillation by setting ‘count by’ and ‘averaging’ appropriately

on signal processor (refer to signal processor manual).

Fluctuations can be caused by

moisture in the cable conduit,

junction boxes, or PCBs.

Problem likely to be noticed on

system that previously functioned

correctly.

Check conduit, junction boxes and PCBs for water contamination. Find

water entry source and correct problem. Dry with a hair drier. Remove/

replace corroded parts and materials.

CAUTION: If using sealant to eliminate water entry, use Sikaflex 1A

polyurethane sealant or Dow Corning RTV 739 or RTV 738. Other sealants

may contain acetic acid, which is harmful to sensors and electronics.

Fluctuations can be caused by

jammed bolts or heat radiation/

conduction.

Problem likely to be noticed

shortly after initial installation

or on system that previously

functioned correctly in cool or

overcast weather.

Loosen nuts on top bolts and inspect top bolts.

• Top bolts free to move in holes: If vessel is heated, it may be radiating or

conducting heat through vessel legs and affecting Load Stand sensors.

• To reduce head radiation/conduction:

a. Insulate vessel.

b. Contact K-M to discuss adding a high temperature insulating pad.

• Top bolts jammed: Jammed top bolts indicate undersized bolt holes on

vessel mounting flange and/or vessel support movement beyond limits of

Load Stand clearance holes. Resulting side loads affect Load Stand

sensors.

• To reduce side loads:

a. Enlarge vessel mounting flange bolt holes to provide additional

clearance.

Fluctuations can be caused by

damaged Load Stand sensor.

Problem likely to be noticed

shortly after initial installation

or on system that previously

functioned correctly.

Using Digital Multimeter (DMM), check resistance for individual Load Stands:

1. Set meter resistance scale to accommodate measured range up to

20,000 ohms.

2. At the suspect Load Stand junction box, remove wiring at TB1 and TB2,

which connects to other Load Stands and signal processors.

3. Put one DMM lead on W and other lead on R terminal on TB1 of Load

Stand junction box. Record resistance, and verify it is 7,660 ± 200 ohms.

If reading is outside this range, one or more Load Stand sensors are

damaged and must be replaced— go to Step 7 to identify which sensor

is damaged.

4. Put one DMM lead on W and other lead on B terminal on TB1 of Load

Stand junction box. Record resistance, and verify it is 7,660 ± 200 ohms.

If reading is outside this range, one or more Load Stand sensors are

damaged and must be replaced — go to Step 7 to identify which sensor

is damaged.

5. Verify readings from Steps 3 and 4 are within 200 ohms of each other. If

not, one or more Load Stand sensors are damaged and must be

replaced — go to Step 7 to identify which sensor is damaged.

6. Repeat Steps 2 through 5 for each suspect Load Stand, until Load Stand

with damaged sensor is located.

7. Continued on next page.