Kistler-Morse KM Load Stand II User Manual

Page 13

9

www.kistlermorse.com

97-1100-01 Rev. H

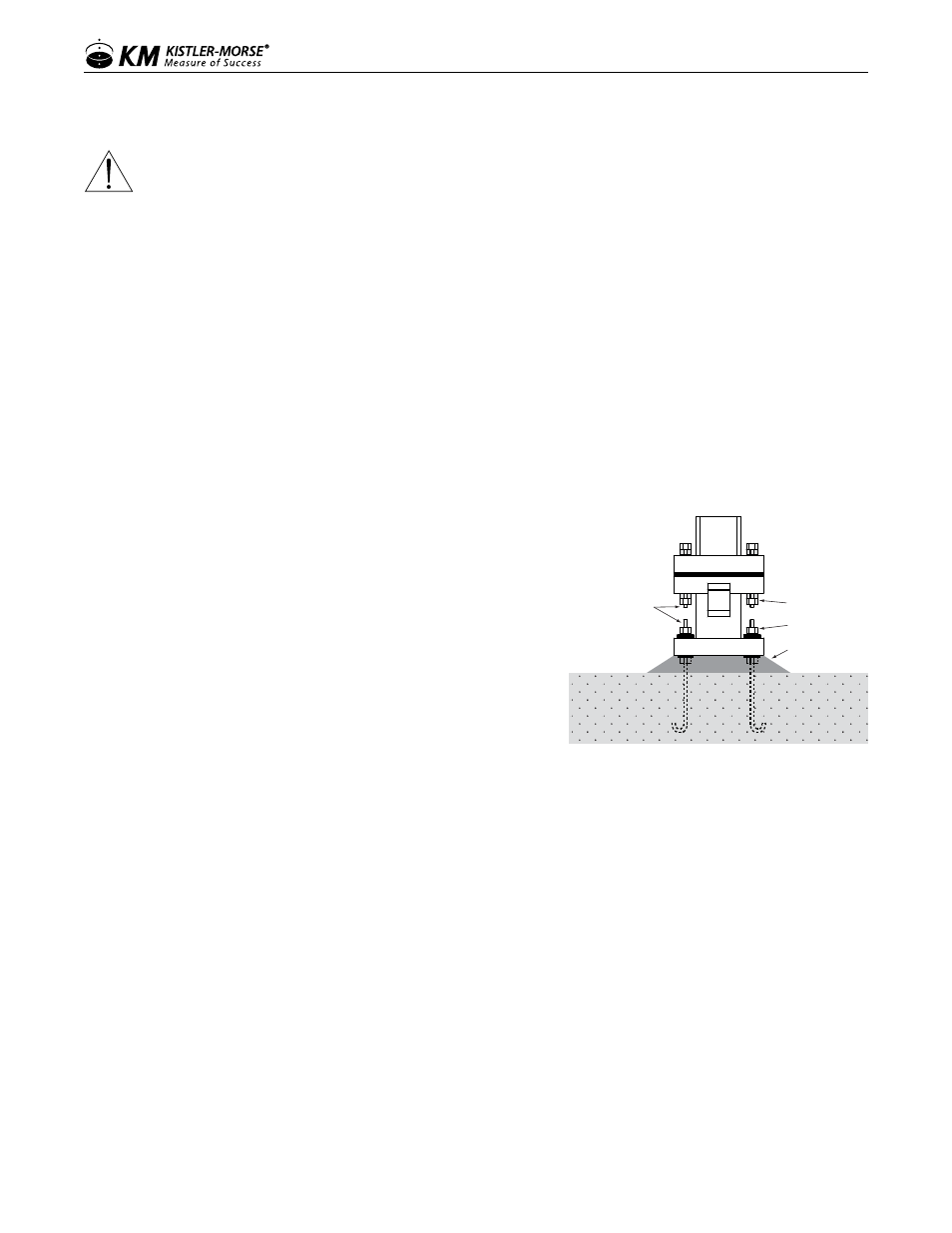

Apply Threadlocker

Tighten 1

1

/

2

turns

past finger tight

Tighten per UBC

Install grout

2. Level the vessel.

caution: LooSen the toP BoLtS on aLL the LoaD StanDS BeFore raiSinG the veSSeL.

a. Raise the vessel legs for the low output load stands.

b. Raise or lower the leveling nuts or add shim(s) above the rubber pad as required adjusting the

distribution of weight on the Load Stands. Raising the leveling nuts and/or adding shims increases

the weight on the Load Stand. Lowering the leveling nuts decreases the weight on the Load Stand.

note: Adjusting leveling nuts and/or shimming on one Load Stand affects the weight distribution on all Load Stands.

c. Slowly lower the vessel leg onto the Load Stand assembly.

d. Repeat Step 1, rechecking the output of all the Load Stands and recalculating the Output Change

(dead weight output - no-load output).

e. Repeat Steps 2A through 2D until the installation meets the criteria for weight distribution.

3. Complete Installation: Once the vessel is level, complete the installation:

a. Tighten the nuts on the anchor bolts per the local code.

b. Verify readings.

c. Tighten the nuts on the upper bolts 1/2 turns past finger

tight. This will compress the rubber washers and rubber pad.

d. Apply threadlocker to the upper bolts and anchor bolts to

prevent loosening of the nuts.

e. Pack grout or concrete under the Load Stand. Do not grout

above the bottom edge of the Load Stand assembly.

f. Replace the junction box cover if not ready to begin

wiring the junction boxes together and to the signal

processor, to ensure no moisture enters the box.