Kistler-Morse KM Load Stand II User Manual

Page 11

7

www.kistlermorse.com

97-1100-01 Rev. H

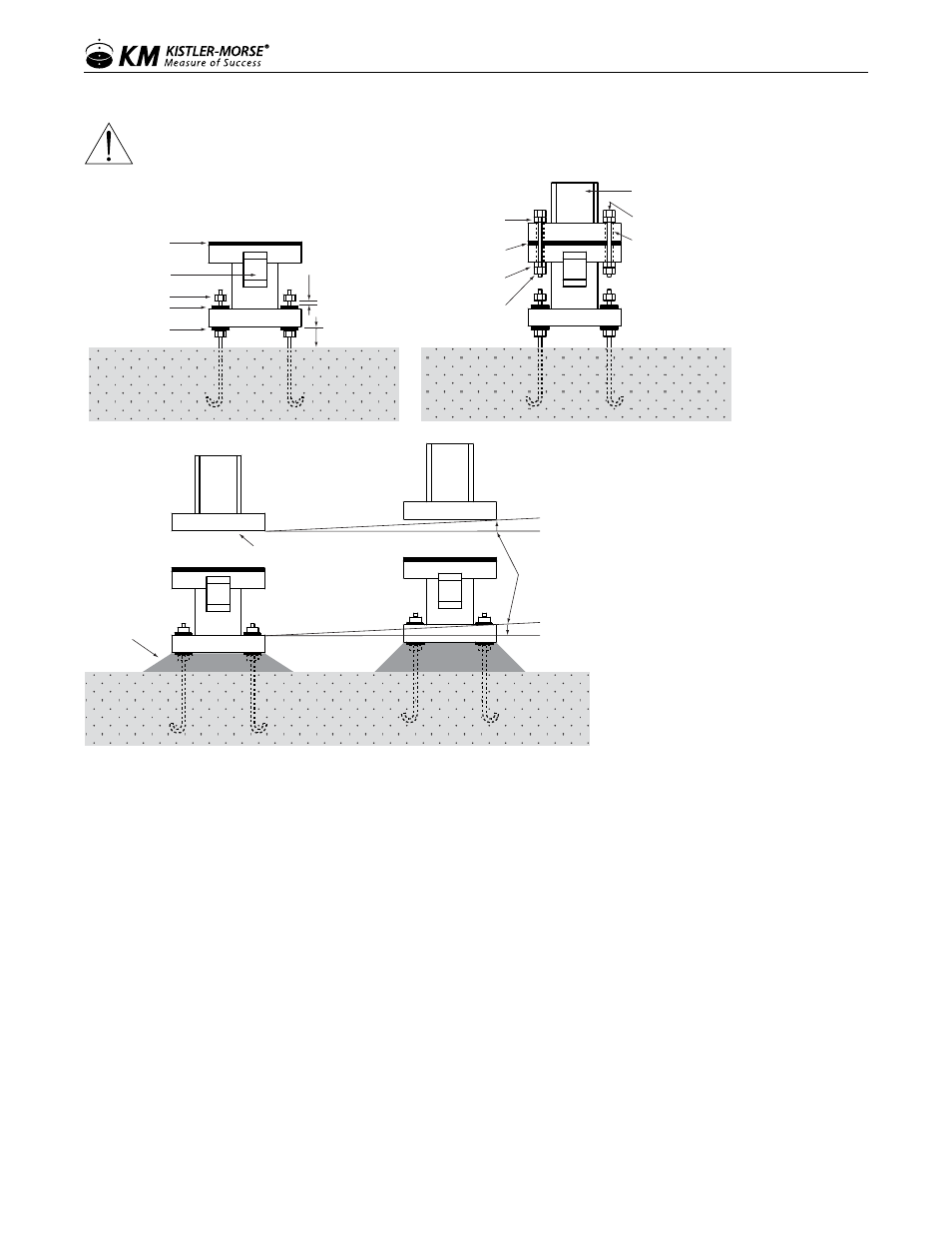

caution: iF inStaLLinG ShiMS, LooSen the toP BoLtS on aLL the LoaD StanDS BeFore

raiSinG the veSSeL.

Rubber Washer

From Kistler-Morse

Vessel Leg and

Mounting Plate

Bolt

Center Load Stand

top mounting holes

with vessel mounting

holes. Center bolts in

mounting holes.

(Bolts and holes shown

for clarity.)

Rubber Pad

From Kistler-Morse

Rubber Washer

From Kistler-Morse

Nut

Rubber Pad

From Kistler-Morse

Junction Box

Leave 1/4 in.

(6 mm) Gap

Minimum 2 in.

(51 mm) for Grout

Nut

Washer

Leveling Nut

and Washer

Grout:

Not installed

until after vessel

is leveled.

Vesssel Mounting Surface

No more than

minimum of ±1º

or 1/4 in. (6 mm)

LeveLinG the veSSeL

Leveling the vessel distributes the weight evenly on all the Load Stands, increasing system accuracy. Perform

this procedure while the vessel is still empty:

1. Check if Leveling Needed

a. Remove the junction box cover.

b. Connect the red, white, and black wires of a 3-conductor cable to the corresponding terminals on TB1 of

the Load Stand junction box. Connect the other end of the cable to the corresponding terminals of the K-M

Test Meter. Turn on the power to the Test Meter and set the Simulate/Test switch to the Test position.

note: If a Kistler-Morse Test Meter is not available, before proceeding refer to Set-Up; Alternate Method for

Checking Output.

c. Verify the dead weight voltage output of the Load Stand from step 3f.

d. Calculate the change in output, as shown in the example. Output Change = uninstalled output

- installed output. The change in output must be positive.