1 operating principle, 2 drive motor, 3 obligations of the operator – FRITSCH PULVERISETTE 15 User Manual

Page 8: Safety information and use

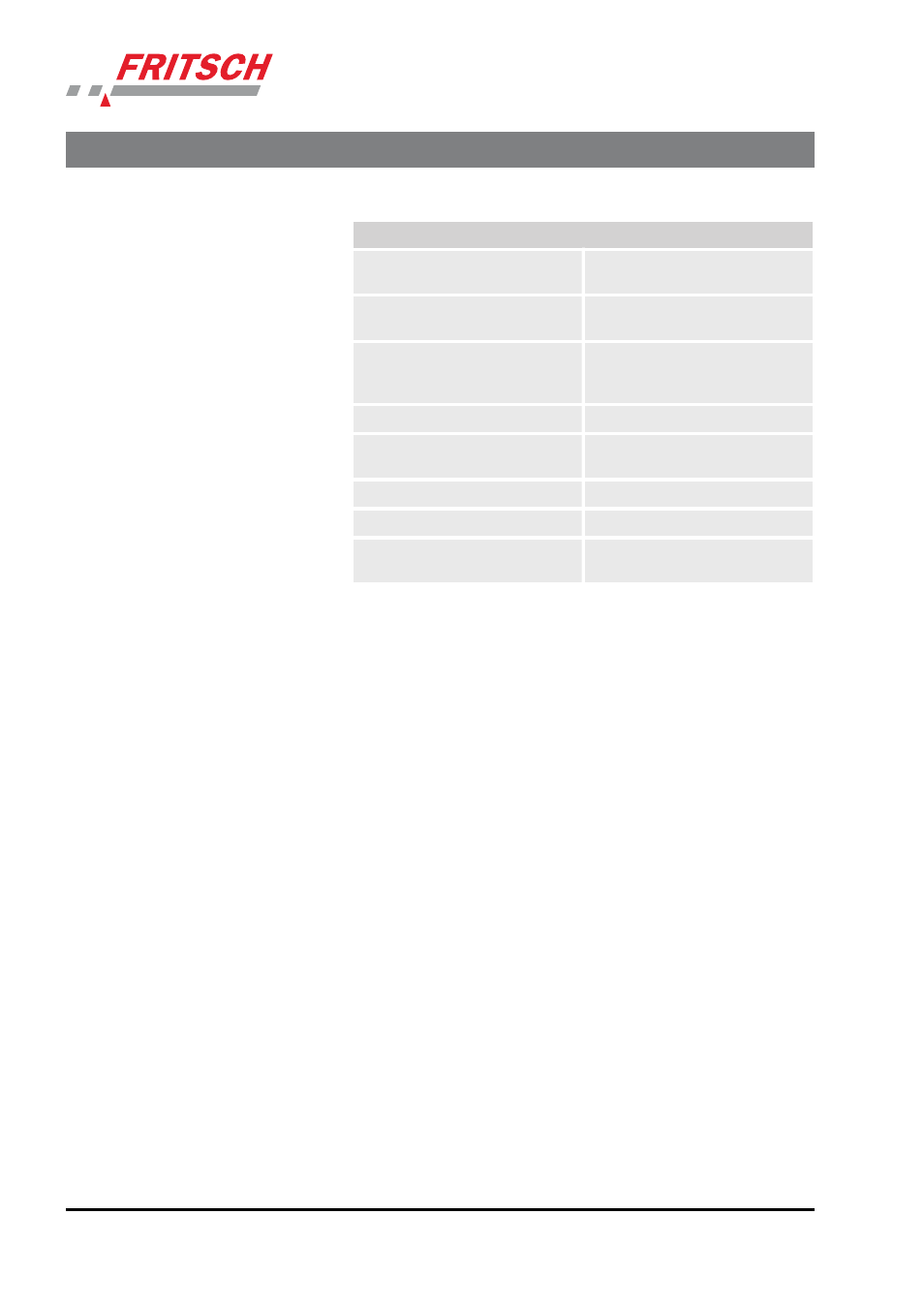

Ideal for comminution of:

Plastics and textiles

Plastics, rubber, leather, mesh

wire, fibres

Agriculture and forestry

Wood, leaves, roots, animal feed,

grain, corn, peat, tobacco

Environment

Paper, cardboard, refuse-derived

fuel, metal-free refuse, household

waste

RoHS

Unprinted circuit boards

Analysis

Coal, horn, coated tablets, pills,

cork, drugs

Construction materials

Refuse-derived fuel

Chemistry

Heterogeneous mixtures

Food

Maize, malt, pasta, herbs, spices,

dried meat

2.2.1 Operating principle

The material to be cut is moved in front of a plunger and fed into the

cutting chamber by means of a funnel. There, four rotating knives in

combination with three fixed knives cut the sample material. The cutting

chamber is closed at the bottom by a sieve insert. Comminuted material

is collected in a pot after it passes the sieve insert.

2.2.2 Drive motor

Driven by:

n

1~ 100 / 120 V motor,

n

1~ 230 V motor or

n

3~ 230 / 400 V motor.

A three-phase motor or single-phase motor without mechanical brake

serves as the drive.

2.3 Obligations of the operator

Before using the PULVERISETTE 15, this manual is to be carefully read

and understood. The use of the PULVERISETTE 15 requires technical

knowledge; only commercial use is permitted.

Safety information and use

- 8 -