Using the device – FRITSCH PULVERISETTE 15 User Manual

Page 25

5.

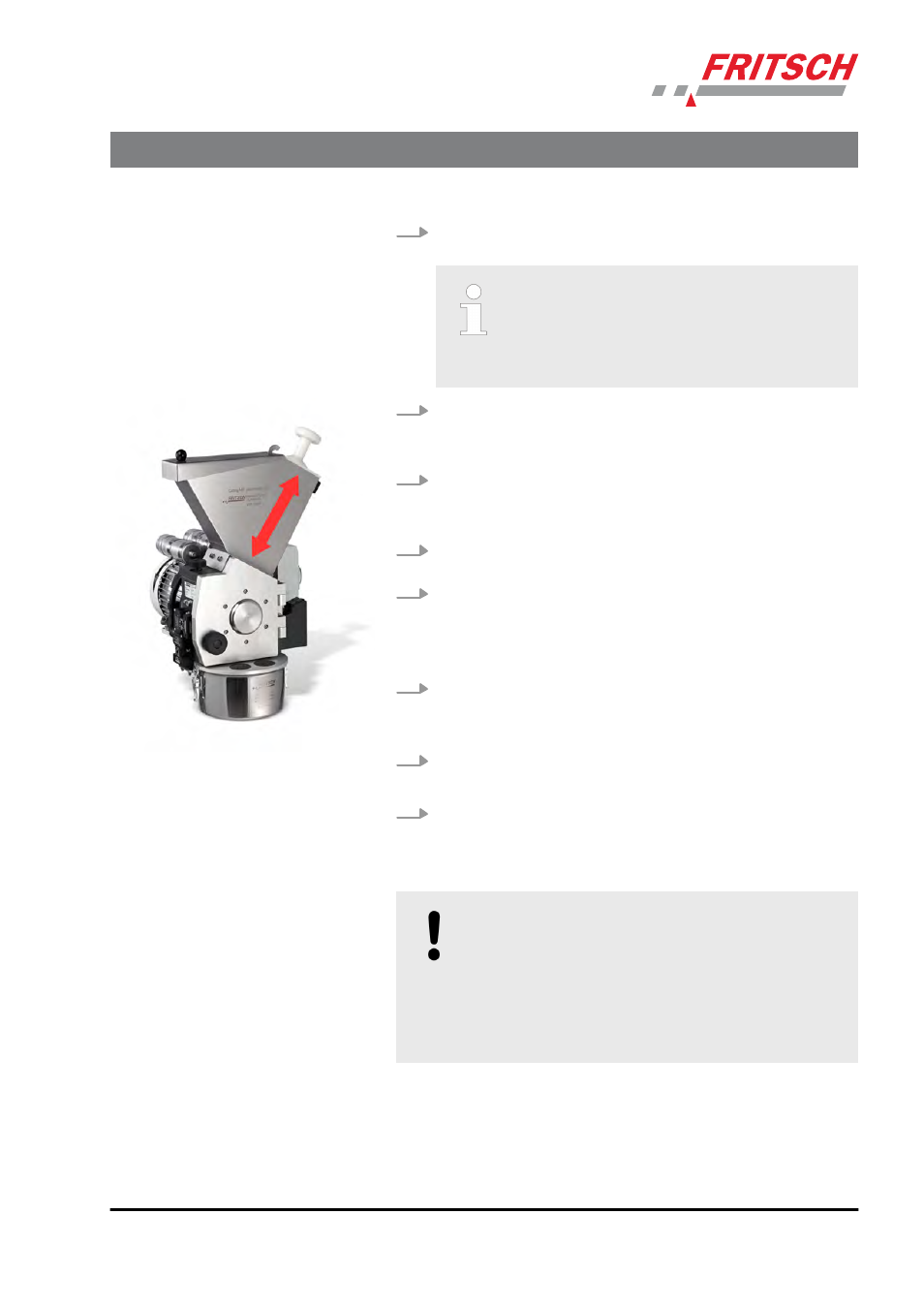

Open the funnel lid, add some comminution material and close

the lid again.

The sample quantity varies depending on the particle

feed size, the hardness of the material and the sieve

size. It is best to start with small quantities and

increase them depending on the success of the com‐

minution.

6.

Close the funnel lid and pull the plunger slowly upward.

ð This causes the material to be cut to fall into the cutting

chamber.

7.

Lower the plunger slowly.

ð The remaining material to be cut is pressed into the cutting

chamber.

8.

Monitor the extent to which the grinding stock is heated; if neces-

sary, arrange for pause times to allow it to cool down.

9.

Make pumping movements with the plunger. These pumping

movements draw in and press out air through the blower filter

above the collecting vessel. This air feeds the comminution mate-

rial through the sieve or lifts it off the sieve and back into the

process.

10.

When the operating noise becomes quieter, the cutting procedure

is complete.

ð More comminution material can be added.

11.

After grinding is finished:

Switch off the cutting mill.

12.

Carefully release both clamping devices of the collecting vessel at

the same time and unhook the collecting vessel from the toggle

latches in order to empty the sample material.

NOTICE!

Only add a quantity of material to be cut which the mill is

able to process correctly.

Too large quantities can cause the cutting mill to become

blocked. Switch off the blocked cutting mill and remove the

material to be cut. Check the gap width before restarting

(see Ä ‘Checking the gap width’ on page 23).

Using the device

- 25 -