3 ventilate after grinding, 4 cleaning the valves, 5 installing valve inserts – FRITSCH PULVERISETTE 4 classic line User Manual

Page 43: Accessories

7.1.2.3

Ventilate after grinding

CAUTION!

Always let the bowl cool down before ventilation. Hot gases

and sample material may escape from the bowl during

pressure equalisation, leading to serious burns.

® Use protective gloves when ventilating!

n

When the bowl has cooled down, remove the additional clamping

system with bowl from the device.

n

Screw the ventilation attachment onto the valve.

Each valve can be used for aerating or ventilating.

n

For pressure equalisation (of the overpressure occurring because of

grinding), carefully press on the ventilation attachment with a thin

object (e.g. hex key).

n

Only now should you release the additional clamping system (5)!

7.1.2.4

Cleaning the valves

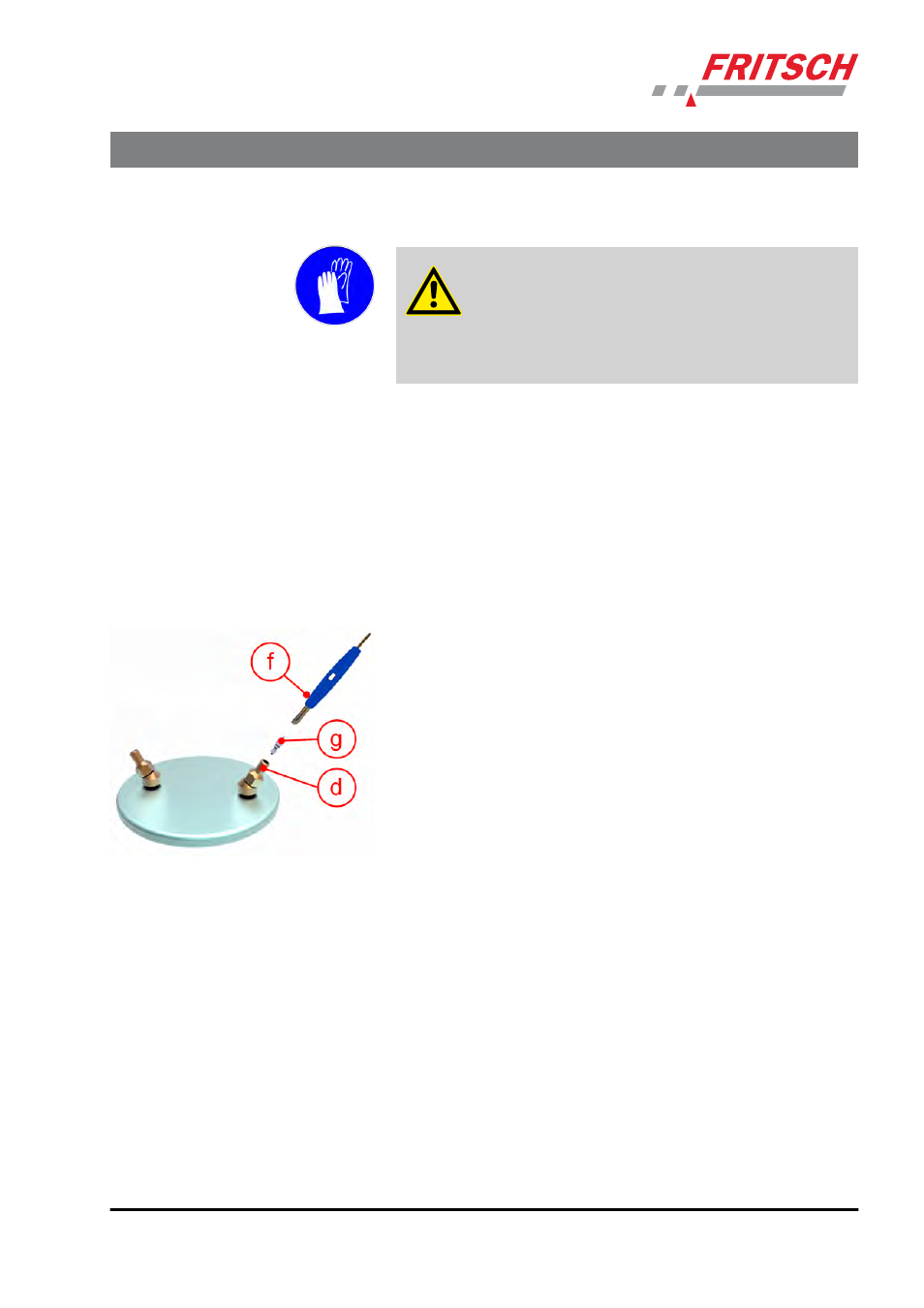

f

Valve screwdriver

g

Valve insert

d Valves

Both valves (d) should be cleaned after every grinding!

n

Insert the thin end of the valve screwdriver (f) from above into the

valve (d) and turn anti-clockwise.

n

Screw out the valve insert (g).

n

Depending on the soiling, clean the valve insert (g) with compressed

air, or place it in a small glass container filled with alcohol and clean

in an ultrasonic cleaner (LABORETTE 17) and then dry carefully.

n

After the two valve inserts have been removed, the two valve

holders can be cleaned with compressed air from above the lid.

7.1.2.5

Installing valve inserts

n

Insert the valve insert (g) into the valve (d) with the spring pointing

upwards.

n

With the valve screwdriver (f), screw the valve insert clockwise.

The following gassing lids for the grinding sets are available, each with

two valves and a soft sealing ring:

Accessories

- 43 -