2 grinding in inert gas with gassing lid, 1 preparation for gassing, Accessories – FRITSCH PULVERISETTE 4 classic line User Manual

Page 41

6.

This is done as described in Ä Chapter 6.5.1 ‘Clamping the 500 ml,

250 ml and 80 ml grinding bowls’ on page 32. However, the hex-

agon screws with the red shaft must be used.

NOTICE!

After tensioning the pressure plate, the hexagon socket

screws of the additional clamping system must be checked

for tightness and tightened again if necessary.

7.1.2 Grinding in inert gas with gassing lid

We carry out a worker water bath test on all gassing lids.

The part to be tested is sealed, a pressure of 5.5 bar is

applied and it is immersed in a water bath. If there is a leak,

bubbles will develop. The air bubbles that develop within a

specific interval are evaluated by the worker/tester.

Only gassing lids with a leak rate of < 10

‐4

[mbar l/s] are

approved.

When grinding in inert gas, the same conditions apply regarding

clamping and composition of grinding set and balls, as apply for standard

grinding.

Two valves are screwed onto the gassing lid through which you can feed

in inert gas (e.g. nitrogen) before switching on the mill. A Viton flat seal is

used instead of a Teflon one.

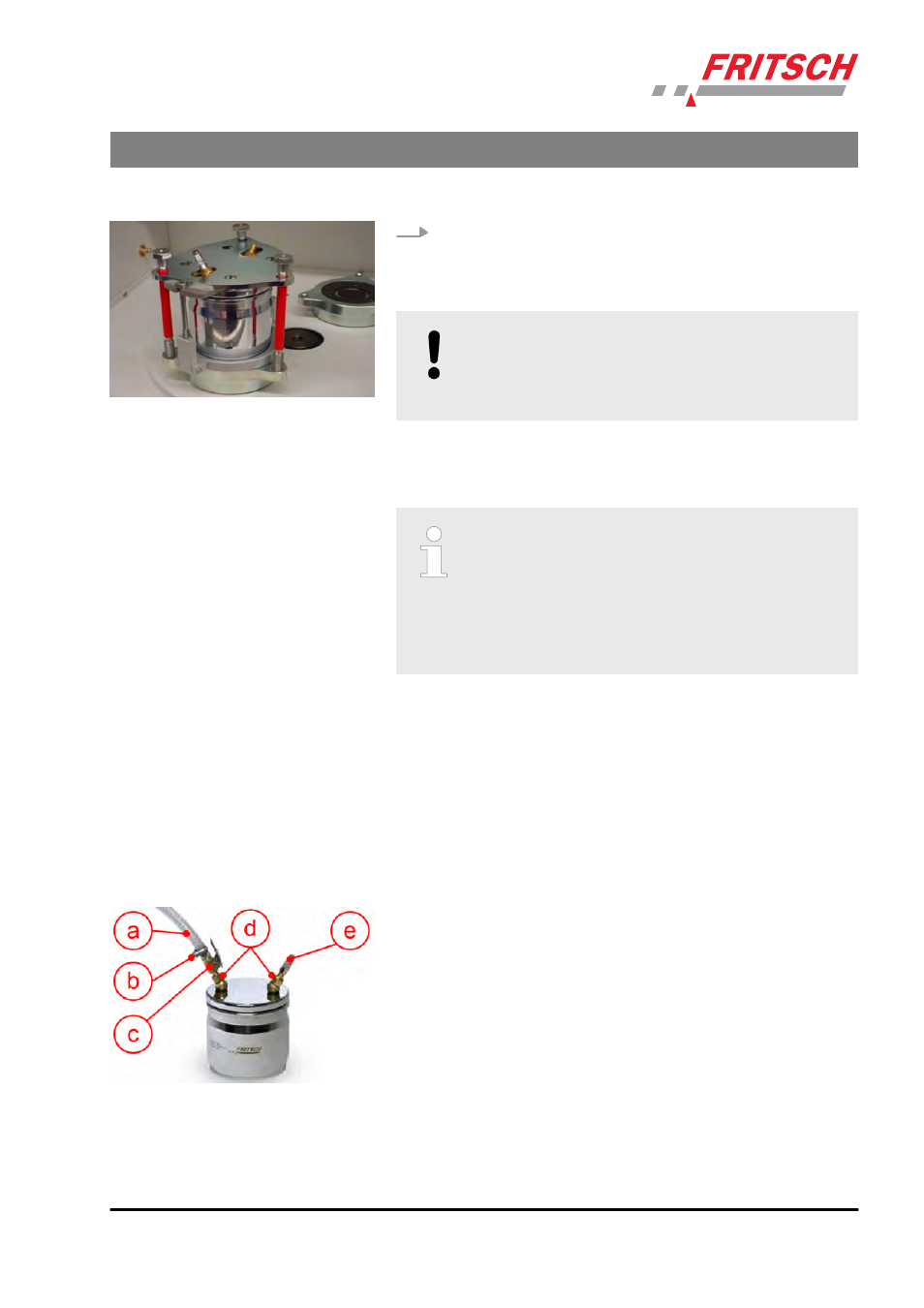

7.1.2.1

Preparation for gassing

a

Gassing hose

b Hose clamp

c

Coupling

d Valves

e Ventilation attachment

n

Fill the grinding bowl with grinding balls and grinding stock. (See

Chapter 6.3 ‘Filling the grinding bowl’ on page 29)

n

Put on lid with seal (use Viton seal).

n

Insert the grinding bowl (closed with an additional clamping system)

into the grinding bowl holder (8).

n

Lock the grinding bowl with gassing lid or grinding bowl with addi-

tional clamping system in the device. (see Ä Chapter 6.5.1 ‘Clamping

the 500 ml, 250 ml and 80 ml grinding bowls’ on page 32)

Accessories

- 41 -