Checkline BL2 User Manual

Page 9

© Electromatic Equipment Co., Inc.

-20-

26.0

MOST COMMON REASONS FOR MISS READINGS WITH BL2 HAMMER

• Product temperature out of application range

Material below 0°C resp. above +50°C (32 to 122 °F) may cause faulty

measurements.

• Temperature difference between meter and sample

Please ensure that the device and the material under test are being stored at the

same temperature (+/-3°C) before measuring. A high temperature difference has

a negative effect on the stability of the measurement results.

• Wrong calibration curve

Before you measure your sample, double check the correct selection of the

calibration curve.

• Frozen wood or beetle infested wood

If you measure such products, the accuracy will decrease.

• Measurement through bark

In fact of that the accuracy will decrease.

• Direct solar radiation

27.0

MOST COMMON REASONS FOR MISS READINGS WITH FLW TESTER

• Product temperature out of application range

Material below 0°C resp. above +40°C (32 to 104 °F) may cause faulty

measurements.

• Temperature difference between meter and sample

Please ensure that the device and the material under test are being stored at the

same temperature (+/-3°C) before measuring. A high temperature difference has

a negative effect on the stability of the measurement results.

• Water film at the measuring head

After measuring wet material a water film can arise on the sensor head. This

could lead to a too high result in the following measurement. After measuring

wet material clean both black plastic parts accurately with a dry cloth.

© Electromatic Equipment Co., Inc.

-9-

9.0

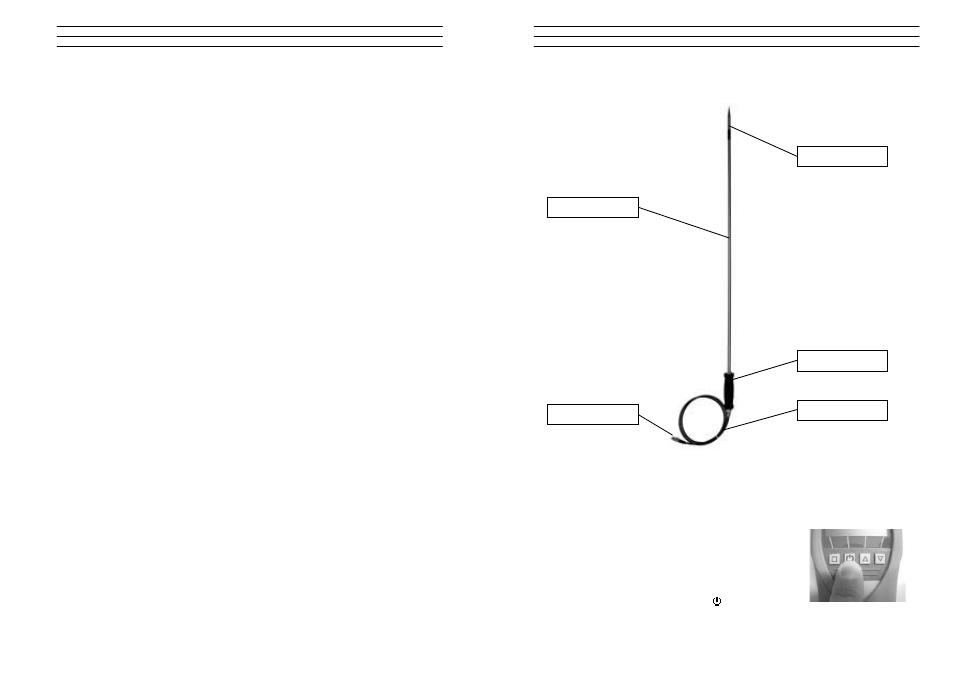

DESIGN FLW TESTER (ART. NO. 12119)

10.0

MEASURING PROCEDURE FLW TESTER

1. For a correct measurement please ensure that the

device has the same temperature than the material (+/-

3°C). For that reason, let your FLW tester adjust to the

surrounding temperature of the material before

measuring.

2. Switch on the device: Press the key for three

seconds.

Measuring tip

Handle

Sensor cable

Plug

Insertion probe