Checkline TS2P User Manual

Page 4

– 4 –

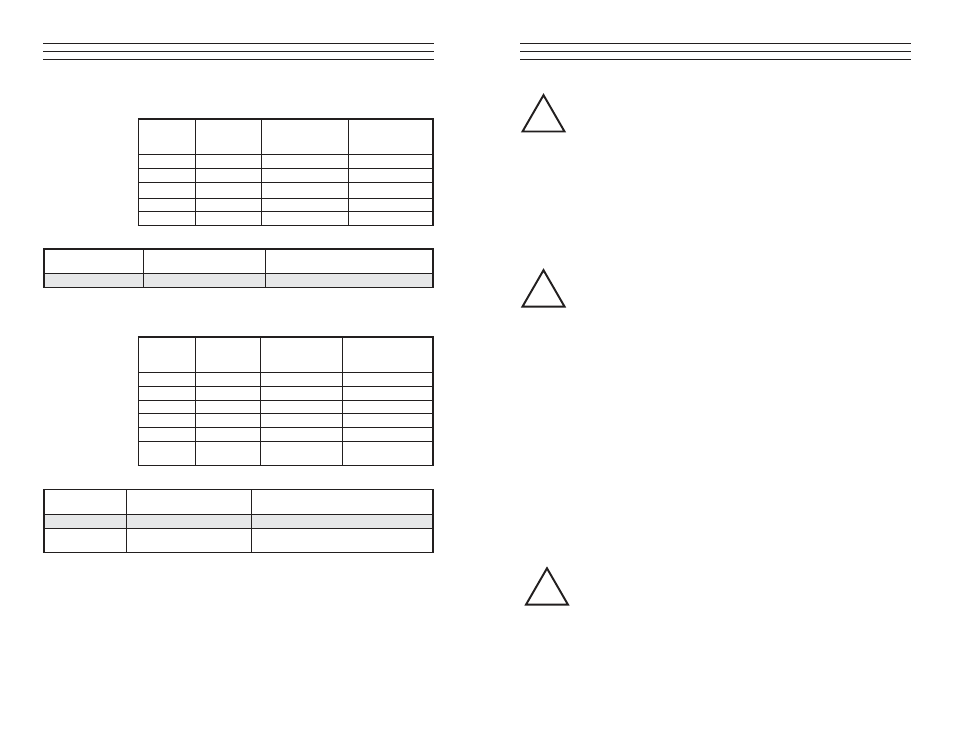

2.2 TS2P Models

2.3 TS2H Models

TS2P Guide Rollers

Model

Tension

Ranges [g]

*Measuring Head

Width [mm]

**Factory

Calibration

Material

TS2P-50

0 - 50

64

PA: 0.12 mm Ø

TS2P-100

0 - 100

64

PA: 0.12 mm Ø

TS2P-200

0 - 200

64

PA: 0.12 mm Ø

TS2P-500

0 - 500

64

PA: 0.20 mm Ø

TS2P-1K

0 - 1000

64

PA: 0.30 mm Ø

Ceramic Pins

Line Speed

[m/min ... max.]

Pin Material

Standard

2000

Oxid ceramic 5.2 mm Ø

TS2H Guide Rollers

Model

Tension

Ranges [g]

*Measuring Head

Width [mm]

**Factory

Calibration

Material

TS2H-1K

0 - 1000

150

PA: 0.30 mm Ø

TS2H-2K

0 - 2000

150

PA: 0.50 mm Ø

TS2H-5K

0 - 5000

150

PA: 0.80 mm Ø

TS2H-10K

0 - 10 Kg

200

PA: 1.00 mm Ø

TS2H-20K

0 - 20 Kg

240

PA: 1.50 mm Ø

TS2H-50K

0 - 50 Kg

240

Steel rope: 1.5mm Ø

(7 x 7 x 0.20)

V-Groove

Line Speed

[m/min ... max.]

Roller Material

Standard

4000

Hardened-steel roller

U-Groove

Code R1

4000

Hardened-steel roller (radius 5)

– 9 –

WARNING: When threading the process material through the rollers, follow

the material path symbol on the front of the sensor. If a force is applied to the

middle sensor roller in the incorrect direction, damage could result.

4. Install the sensor in the desired position at the measuring location using the

provided mounting holes.

5. Allow approximately ten minutes for thermal stabilization of the sensor.

6. Thread the process material through the measuring and guide rollers, following

the material path symbol on the front of the sensor.

WARNING: When threading the process material through the rollers, follow

the material path symbol on the front of the sensor. If a force is applied to

the middle sensor roller in the incorrect direction, damage could result.

NOTE: Since ZERO and GAIN adjustments are always performed

statically, the readings may differ under dynamic load.

7 Hang a weight that corresponds to e.g. 10% of the tension range from the

process material.

8. Connect a volt meter to pins 4 and 5 of the connector on the rear side of the

unit.

9. Adjust the potentiometer, which you can reach through the ZERO hole in the

housing, with a screwdriver (with a point width of max. 1.9 mm) until the

display of the connected volt meter reads,

for example:

Sensor model TS2 - 200:

Weight 20 g = Display 0.100 V for the TS2 standard version

or

Weight 20 g = Display 1.00 V for the TS2 version with 10 V output signal.

WARNING: Do not insert the screwdriver at an angle as this may damage

the potentiometer.

!

!

!