0 introduction, 0 changing sheaves, 1 unpacking 1.2 description – Checkline CTM User Manual

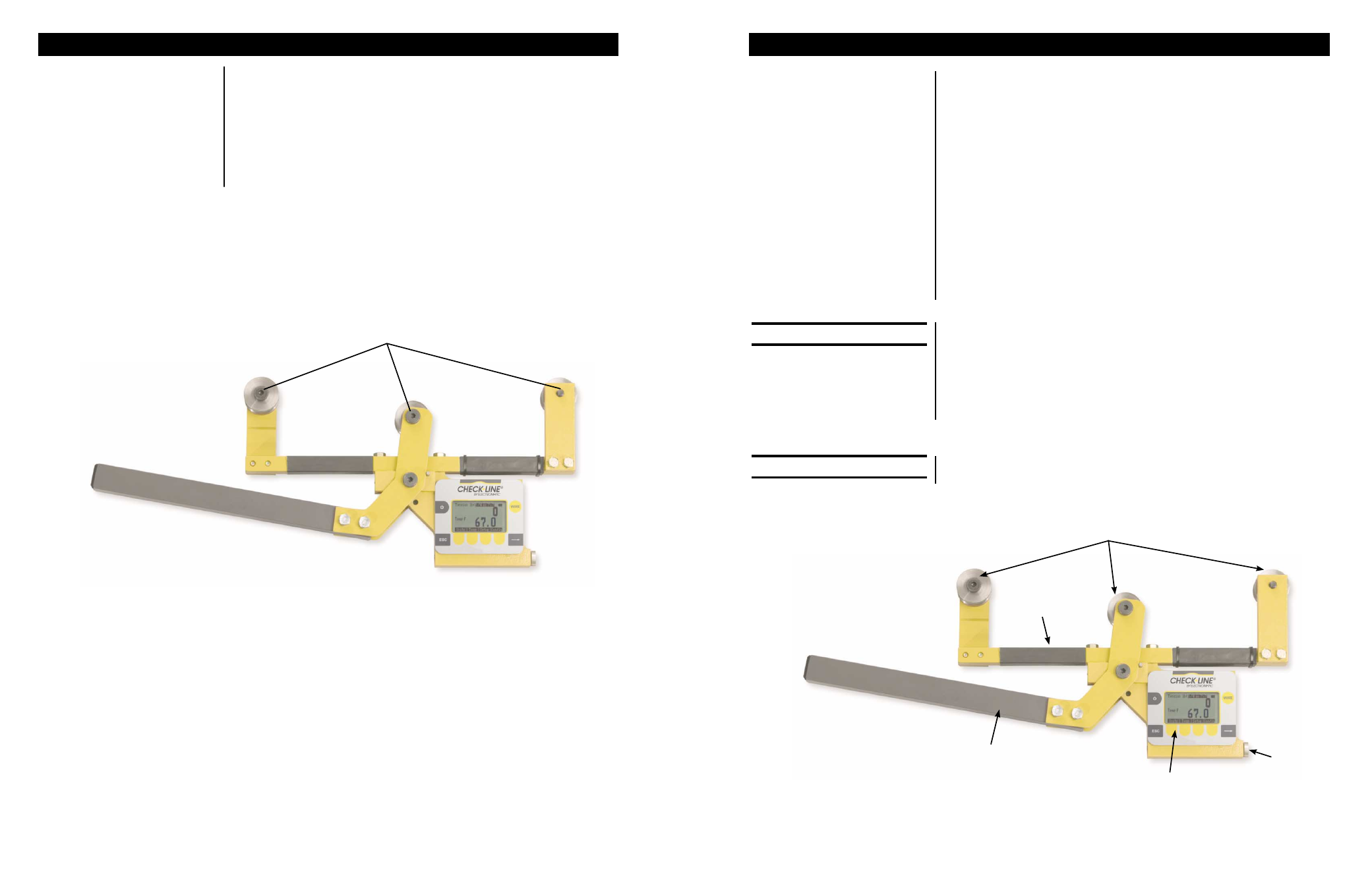

Page 3: Figure 1, Figure 7 changing sheaves

1.0 Introduction

1.1 Unpacking

1.2 Description

This manual covers the setup and operation of the CTM Clamp Line Ten-

siometer. The CTM is a simple, accurate strand dynamometer. It is can be

clamped onto a cable, accurately determine the wire tension and be re-

moved in seconds.

The CTM can handle multiple wire diameters, it can display live tension, dual

live/peak tension, average tension captured from several tests, dual tension/

temperature display and a check-tensioning graphical display.

With its battery-powered electronic interface, setup and operation is made

simple with on-screen prompts.

This manual covers the following:

• Unpacking

• Setup

• Operation

• Maintenance

• Troubleshooting

When you receive your CTM, unpack it and inspect the container and the

instrument for any damage. Report any problems to the shipping company

immediately and save the packing materials.

Insert 2 AA batteries into the battery compartment, shown in Figure 1. Your

CTM probably comes from the factory with the proper sheave size installed

and calibrated for your application. If not, follow the setup directions later in

section 3.0 Confi guration Mode and 4.0 Changing Sheaves.

The CTM is shown in Figure 1 with the parts labeled.

Sheaves

Lever arm

Support arm

Front panel

Battery

compartment

Figure 1

3

4.0 Changing Sheaves

As you use the CTM on different diameter cables you must change to the

correct sheave size. To change sheaves, remove the hex head screws

pointed out in Figure 6 below. Replace the sheaves with the correct letter

sheave and reinsert the screws and tighten.

Insure sheaves installed agree with sheaves noted in the Wire calibration.

Exception: Sheaves match the wire diameter of the cable to be measured

and alternate calibration is selected as per section 5.2.

Insure that the wire rope is riding in the groove of all three sheaves.

Screws

Figure 7

Changing sheaves

Do not use the CTM with cable

larger than indicated on the

sheaves. Overload and dam-

age to the instrument may

result.

Do not mix sheave sizes. This

will result in inaccurate mea-

surement and possible over-

load.

14