Checkline TI-25M-MMX User Manual

Page 8

– 8 –

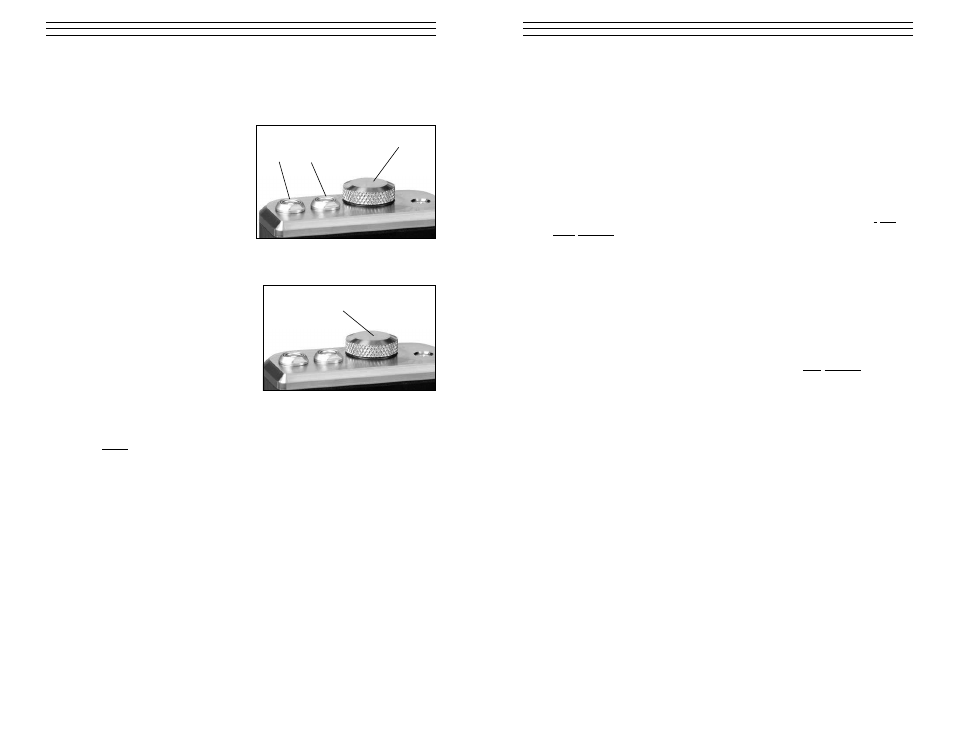

3.7 Probe Connector Receptacle

Located on the top edge of the TI-25M-MMX housing are the receptacles

for the probe and the probe zero plate.

The connectors for the probe

are non-polarized so the con-

nector at the end of the probe

cable can be inserted into

this receptacle in either

orientation. Make sure the

connector is “well seated” in

the receptacle.

3.8 Battery Compartment (Changing The Battery)

The battery compartment is

located under the probe zero

test plate. To open the battery

compartment, unscrew the

probe zero plate by rotating it

counterclockwise. The

TI-25M-MMX operates on

two (2) AA Batteries (1.5 V).

If desired, rechargeable

batteries may be used.

The TI-25M-MMX is shipped with the batteries installed. Insert batteries in

the polarity indicated on the rear label.

Note: When the display elements begin to flash off and on repeatedly, the

batteries are low and should be replaced.

Battery Cover

Probe Receptacles

Probe Zero

Plate

– 21 –

1 1 .0 CALI BRAT I ON FOR M EASU RI N G T H I CK N ESS OF

M AT ERI ALS OT H ER T H AN ST EEL

Ultrasonic Thickness Gauges use sound waves to measure wall thickness.

Different types of materials have different inherent acoustic velocities. For

instance, the acoustic velocity of steel is 0.2330 IN/µs (inches-per-microsecond),

versus that of aluminum, which is about 0.2500 IN/µs. It is critical that the

TI-25M-MMX be set for the correct acoustic velocity depending upon the materi-

al to be measured.

The TI-25M-MMX is shipped from the factory calibrated for steel with an

acoustic velocity of 0.2330 IN/µs (5920 M/s). To measure the thickness of any

other material, the calibration will have to be changed by adjusting the acoustic

velocity to the appropriate value for the specific material being measured.

To determine the proper acoustic velocity for the non-steel material, refer to the

Acoustic Velocity Table, section 10.1. After determining the proper acoustic

velocity, the gauge must be re-calibrated for this new value.

If you do not know the type of material to be measured or if the material type is

not listed in the Acoustic Velocity Table follow the following procedure.

11.1 Changing Calibration - Acoustic Velocity Is Not Known

In applications where the type of material is not known or the material is

not listed in the Acoustic Velocity Table, the following procedure can be

used to calibrate the gauge for highest accuracy.

1. Obtain a sample of the material with a known thickness or use a

micrometer, caliper or similar device to accurately measure it.

2. Turn on the gauge by pressing the ON/OFF key.

3. Place a small amount of coupling fluid on the sample of known

thickness and place the probe on the sample. The Stability Indicator

should have nearly all its bars illuminated. Having achieved a stable

reading remove the probe from the sample.

4. Press the CAL key.

5. The units of measure indicator “IN” or “MM” will be flashing

indicating that you are in the Measurement Calibration mode.

6. Use the UP and DOWN arrow keys to adjust the displayed measurement

value to match the thickness of the known sample. By pressing and

holding the key, the numbers will change more rapidly.