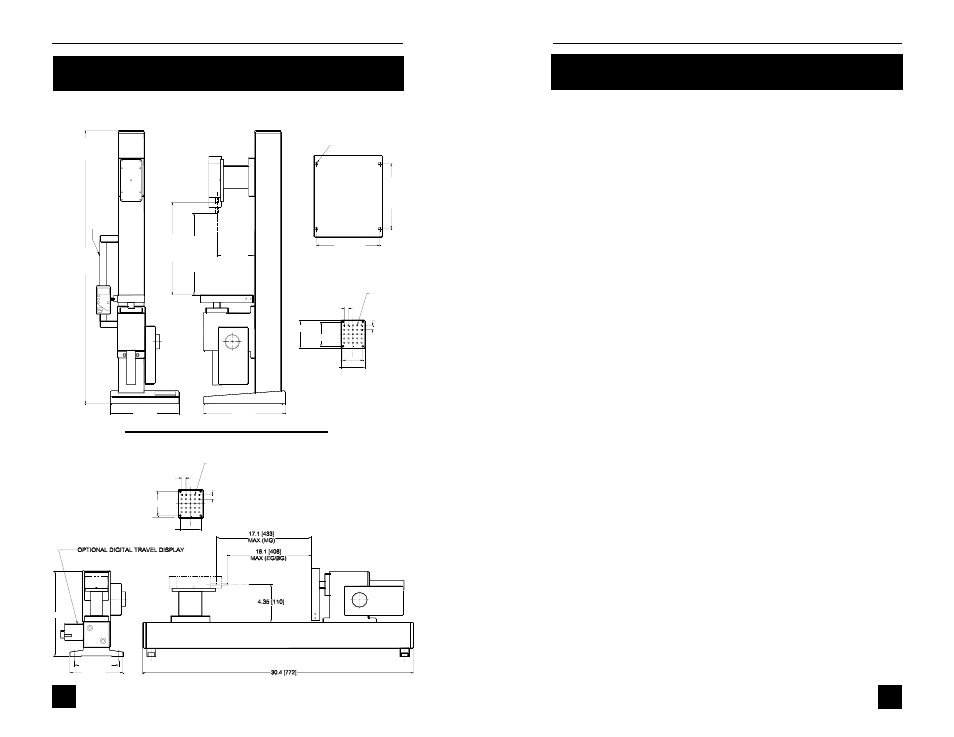

Dimensions, Operation, Series tsf – Checkline TSFM500 User Manual

Page 5: User’s guide, Tsfm500h, Tsfm500

Series TSF

IN [MM]

10.0 [254]

6.0 [152]

5.00 [127.0]

MOUNTING PLATE

TOP VIEW

2.80 [71.1]

#10-32 UNF-2B

X 0.36 DEEP

X25

0.50 [12.7]

TYP

2.30 [58.4]

0.50 [12.7]

TYP

TSFM500 / TSFM500H

TSFM500H

7

2.76 [70.1]

3

1

.5

[

8

0

0

]

9.4 [239]

7.9 [201]

IN [MM]

MOUNTING PLATE

TOP VIEW

5/16-18 UNC-2B

X 0.600 [15.2] DEEP

X4

1

4

.5

[

3

7

4

]

M

A

X

(

M

G

)

1

3

.5

[

3

4

3

]

M

A

X

(

E

G

/B

G

)

4.35 [110]

0.500 [12.7]

TYP

#10-32 UNF-2B

X 0.360 DEEP

X25

O

P

T

IO

N

A

L

D

IG

IT

A

L

T

R

A

V

E

L

D

IS

P

L

A

Y

7

.5

0

[

1

9

0

.5

]

3.26 [82.8]

2.800 [71.1]

2.300 [58.4]

0.500 [12.7]

TYP

BASE PLATE

BOTTOM VIEW

7.30 [185.4]

DIMENSIONS

TSFM500

User’s Guide

TSFM500 / TSFM500H

With the base removed, the test stand can be easily integrated into

large systems such as production lines. In general, the stand can be

mounted on any angle (upside down, for example), although extra care

should be taken during installation and operation.

After the stand is in a stable and secure position, install a force gauge

with four thumb screws (provided). All Mark-10 gauges mount directly

without adapters.

Plug the control unit cable into the 9-pin male connector located above

the motor in the rear of the stand.

Plug the power cord into the remote console and the other end into a

wall outlet.

Turn on the power with the switch located on the control unit beside the

power cord.

The test stand is now ready for operation.

OPERATION

1. Mount the test stand to a firm, flat, and level working surface for

maximum safety and accuracy using four 5/16 screws (not in-

cluded). Use the included mounting hole drill template to accurately

drill the holes. Testing can take place without securing the test stand

in such a manner, however, it is strongly recommended that the

stand be secured.

2. Install a force gauge onto the gauge plate with four thumb screws.

All Mark-10 force gauges mount directly to the stand without adapt-

ers.

3. Install any required attachments, including grips, adapters, and

other materials necessary for your test sample. Make sure these

items are set up in a secure and safe manner.

4. Power on the control unit (further instructions to follow). For fine

adjustment or otherwise manual testing, turn the knob on the right

hand side of the stand clockwise for compression, counterclockwise

for tension.

4