BUCHI Syncor Polyvap User Manual

Page 29

Syncore Platform

29

5 Operation

ping position of the base plate also brings about an exact

positioning of the access used for manual adjustment of the

eccentricity.

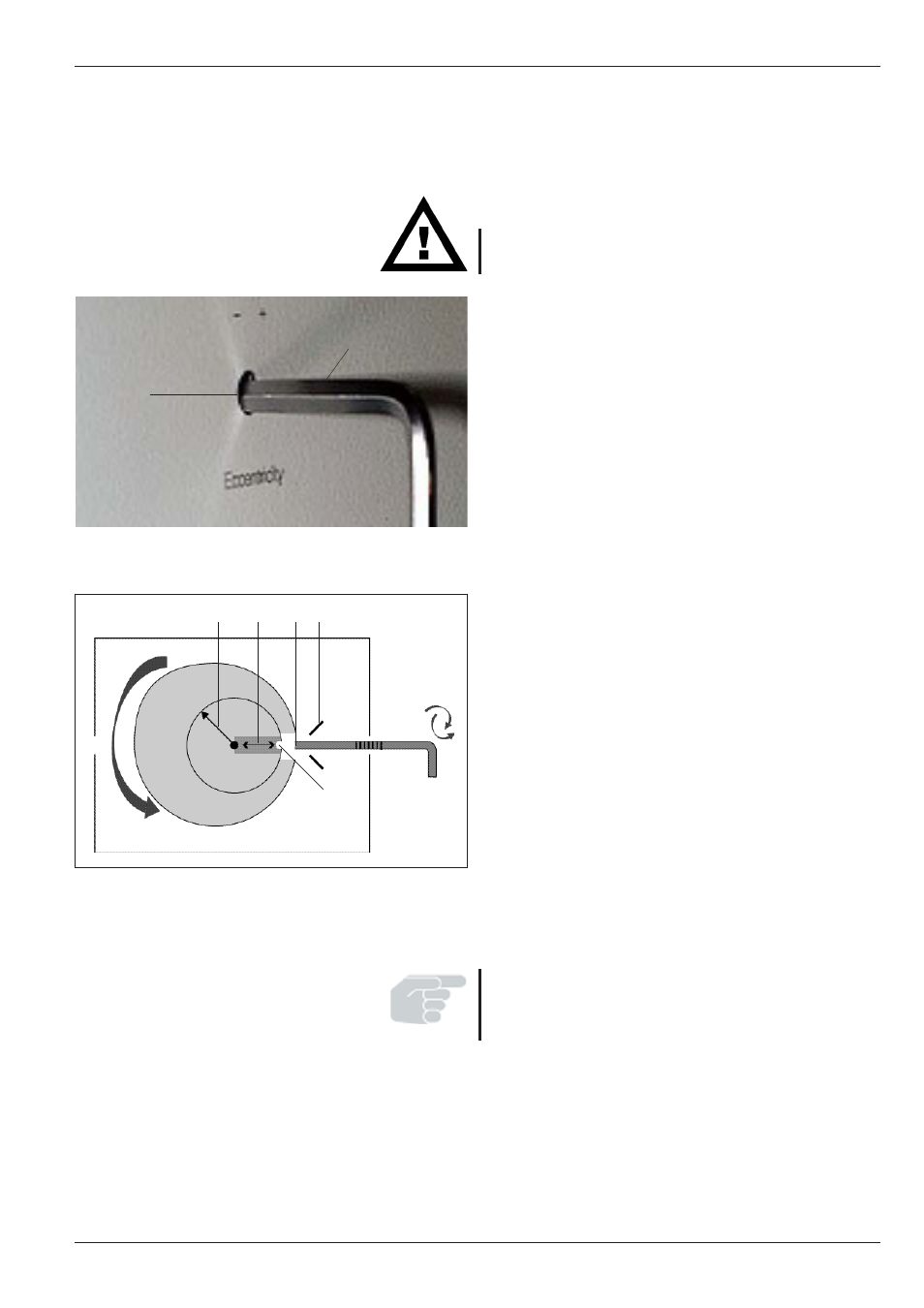

Adjusting eccentricity

Never make adjustments while the base plate is still moving.

The introduction of the tool into the drive unit while it is still

in motion can damage the unit and lead to personal injuries.

The base plate must be in the pre-defined stopping position

be fore any new eccentricity of the vortex movement is set. To

ensure this, switch the unit on and let the base plate rotate

at least one full rotation.

Use the tool supplied to adjust the eccentricity. Insert this

into the opening on the right side of the single platform.

Not visible to the operator:

A narrowing channel on the guide positions the tip of the

tool directly on the set-screw for eccentricity .

• Insert the tool down to the stop tilted slightly upward and

under gentle pressure.

• Turn the tool to adjust the eccentricity of the vortex move-

ment.

• Turn clockwise to increase the eccentricity, up to a maxi-

mum of 5 mm.

• Turn counterclockwise to reduce the eccentricity, down

to a minimum of 0.0 mm.

• One full turn corresponds to a change of 1 mm.

• For reasons of accuracy, the engraving on the adjustment

wrench should be used only for adjusting unbalances.

We recommend first setting the eccentricity to the minimum

value of 0 mm (down to the stop in a counterclockwise direc-

tion). Then reset the desired eccentricity afterwards by turning

the a corresponding number of turns in a clockwise direction.

Figure 21: Introduction of the tools for adjusting the eccentricity

Figure 22: Adjusting eccentricity (schematic)