Heater, Line, Cont'd) – Steffes 1003 User Manual

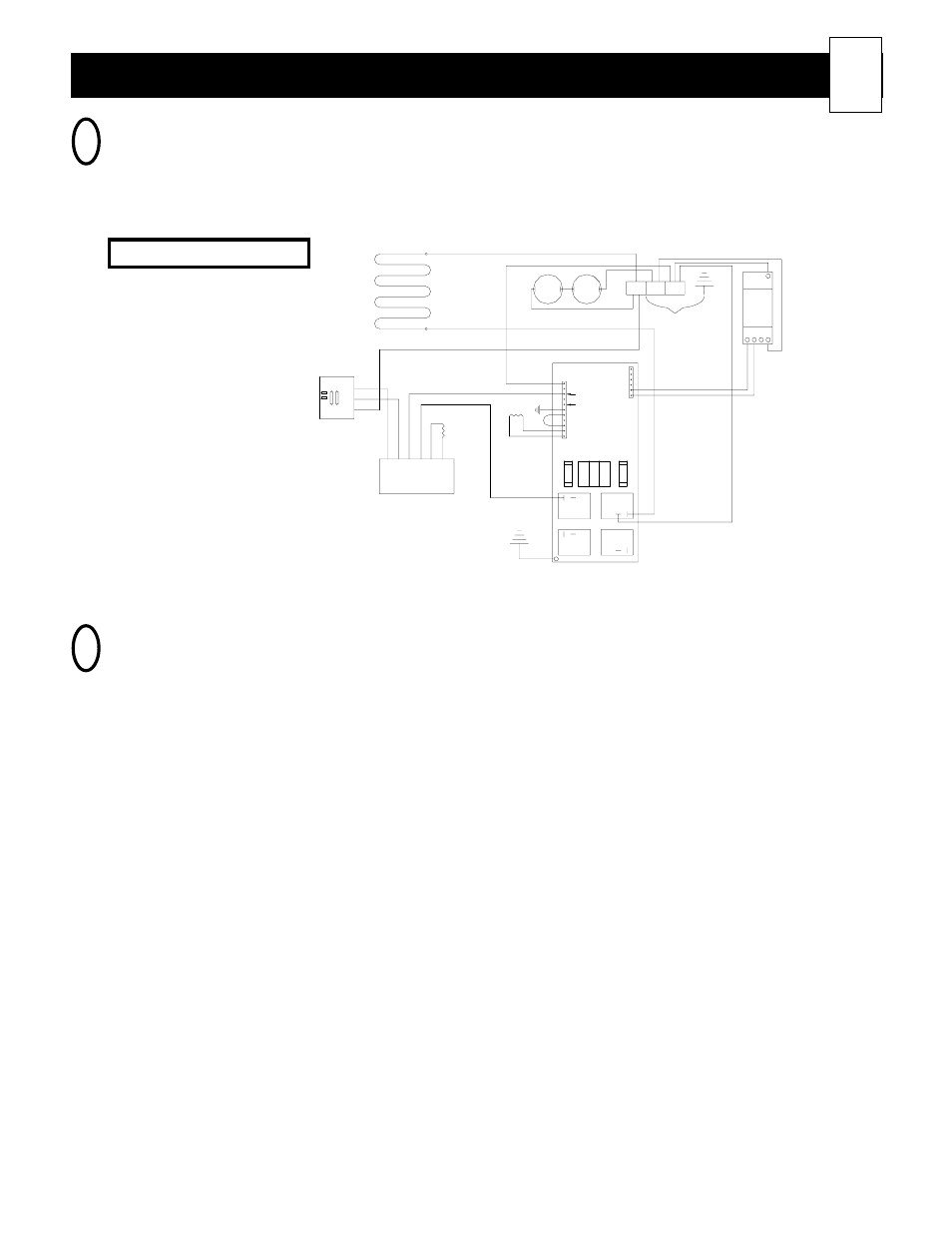

Page 19: Typical contr

LINE

LINE

LINE

LINE

LINE VOL

VOL

VOL

VOL

VOLT

T

T

T

TA

A

A

A

AGE

GE

GE

GE

GE WIRING DIA

WIRING DIA

WIRING DIA

WIRING DIA

WIRING DIAGRAM

GRAM

GRAM

GRAM

GRAM

Connections shown are for 230 VAC heaters. Refer to the Unit Identification Label on the

lower right side of room heating unit for the heating element voltage of your heater.

FIGURE 12

Models: 1002 and 1003

OUTPUT

RELAY 1

"TOP"

"SIDE"

BLUE

BLUE/WHITE

BLACK

DAMPER CONTROL

CIRCUIT

SUPPLY

L

1 2 3 N

CLOCK

TIME

OPTIONAL

LIMIT

290°

LIMIT

290°

RED

NOT

CONNECTED

RELAY

ELEMENT

RELAY 2

OUTPUT

BLACK

L2

L1

T1

H

E

AT

IN

G E

L

E

M

E

N

T

BR

Y

Y R F

O

O

B

DAMPER

CONTROL

RESISTOR

CIRCUIT BOARD

OUTPUT CONTROL

CIRCUIT BOARD

BLACK

BLACK

OUTPUT

RESISTOR

240V

120V

COM

NO

NO

TR

AN

S

3

A

1

A

Heater

Heater

Heater

Heater

Heater W

W

W

W

Wiring

iring

iring

iring

iring

(cont'd)

(cont'd)

(cont'd)

(cont'd)

(cont'd)

5

6

TYPICAL CONTR

TYPICAL CONTR

TYPICAL CONTR

TYPICAL CONTR

TYPICAL CONTROL

OL

OL

OL

OL WIRING INFORMA

WIRING INFORMA

WIRING INFORMA

WIRING INFORMA

WIRING INFORMATION

TION

TION

TION

TION AND DIA

AND DIA

AND DIA

AND DIA

AND DIAGRAMS

GRAMS

GRAMS

GRAMS

GRAMS

The brick core charging of the 1000 series room heating unit is capable of being controlled by low voltage

wiring, by a time clock or WIRELESS with the use of the Steffes Power Line Carrier (PLC) control system.

If using the wireless method, only one PLC system is needed in an installation; and, it can be mounted indoor

or outdoor. It will transmit the load management control switch signal through the entire power line system in

the home or building. In addition to controlling the heater, it will transmit outdoor temperature information

for automatic brick core charging. An installation procedure manual will accompany the PLC control system.

Depending on which method of heating element control is being used, the unit configuration dip switches will

need to be set accordingly. (See Figure 13 for location of these dip switches in the heater.) The function of

each dip switch is as follows:

Dip Switch #1 = Invert Peak Signal (Should be "ON" if using a time clock for control purposes.)

Dip Switch #2 = Not used (Should always remain in "OFF" position.)

Dip Switch #3 = Invert Occupied/Not Occupied Signal (Room Temperature Set Back)

Dip Switch #4 = Invert Anticipated (Pre-Peak) Signal

Dip Switch #5 = Enable Auxiliary Heat Call Feature

Dip Switch #6= Automatic Charge Control Configuration (Should be "ON" if a direct wired outdoor sensor is

being used for automatic brick core charge regulation.)

Dip Switch #7 = Security (Editing Control) Mode

Dip Switch #8 = Used for factory purposes ONLY. (Must always remain in "OFF" position.)

If the dip switch button is set in the up position, the dip switch is in the "ON" (activated) position.

If the dip switch button is set in the down position, the dip switch is in the "OFF" (deactivated)

position. See Figure 13 for location of the dip switches in the heater.

18

Note 1: On 120V systems, the L2 terminal block position MUST always be the ungrounded "HOT"

conductor.

(See Note 1)

NOTE

NOTE