General, Installation – Chromalox ADH-005 User Manual

Page 2

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do so

could result in personal injury or property damage.

Heater must be installed by a qualified person in accor-

dance with the National Electrical Code, NFPA 70.

The system designer is responsible for the safety of this

equipment and should install adequate back-up con-

trols and safety devices with their electric heating

equipment. Where the consequences of failure could

result in personal injury or property damage, back-up

controls are essential.

1. Locate and position heater in duct in accordance with both

process requirements and recommendations given.

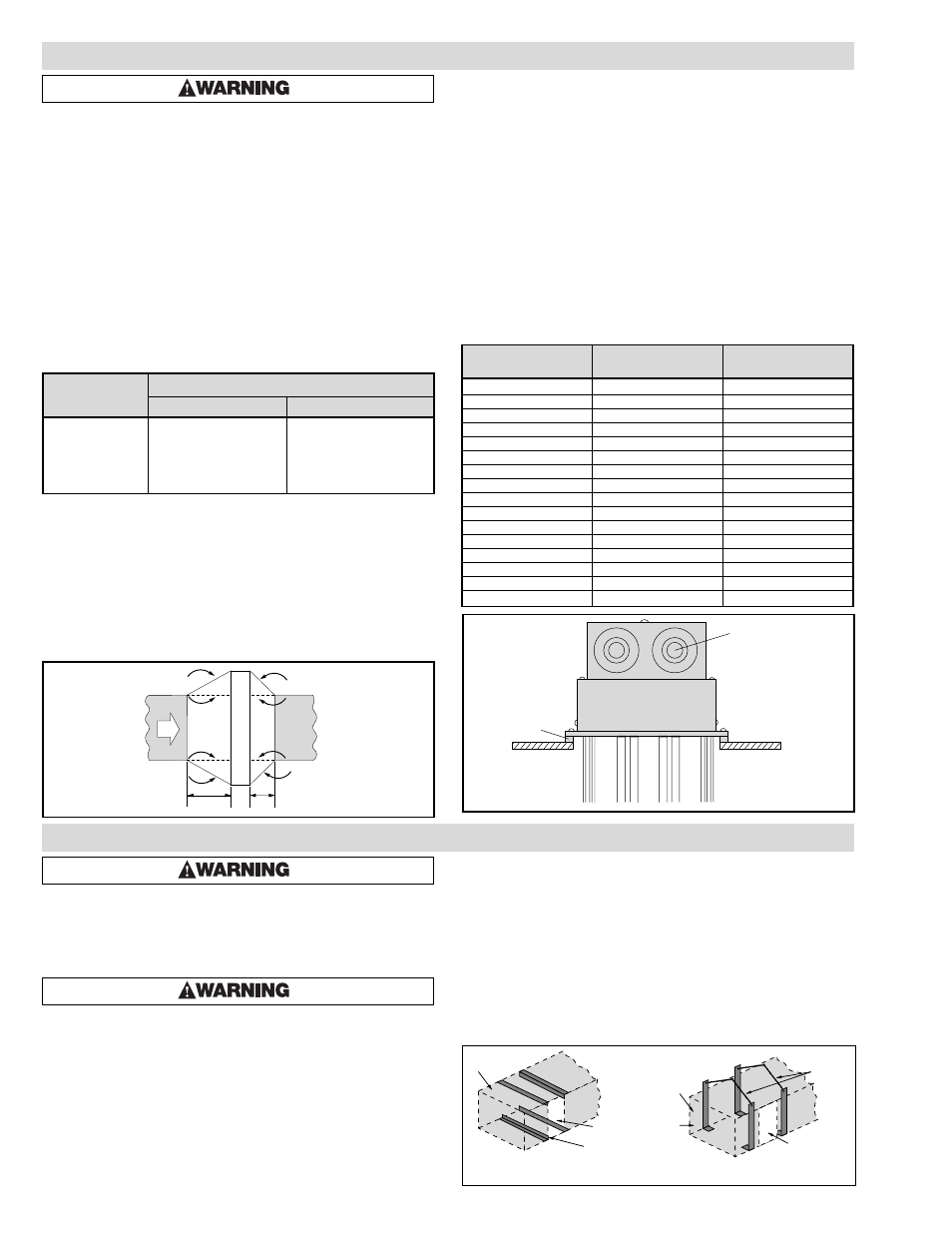

2. Refer to Figures 1 and 2, layout “D” and “M” dimensions on

duct mounting face established in step 1.

3. With tools suitable for sheet metal work, cut layout opening in duct.

4. In general, heaters less than 35 pounds in weight may be mounted

directly in opening without additional duct reinforcement if duct

installation and condition permits. To fasten heater to duct wall use

#14 pan or round head self-tapping screws. The flange mounting

gasket supplied with the heater is recommended for insertion

between heater flange and duct to minimize air leakage.

5. For heater weights greater than 35 pounds (see Specifications

Table A, page 1) due consideration should be given to; (a)

mechanically strengthening duct work with, for example, angle

irons or chains (see Figure 5), and (b) heat insulating duct line

in immediate area of heater location to prevent excessive heat

loss. Consult your local sheet metal contractor.

FIRE/EXPLOSION HAZARD. This heater is not

intended for use in hazardous atmospheres where

flammable vapors, gases, liquids or other com-

bustible atmospheres are present as defined in the

National Electrical Code. Failure to comply can

result in personal injury or property damage.

1. Heater construction characteristics —

A. Alloy sheathed tubular elements, .475” diameter

B. Steel flange

C. Stainless steel support construction

D. High temperature alloy terminals and connections

E. Replaceable individual heating elements

F. Wiring terminals located outside the heated zone

2. Maximum Temperatures — Types ADH and ADHT process

air heaters can generally be used at the following maximum

temperatures shown, provided the minimum air velocity is

maintained uniformly through the heater.

CAUTION: Do not energize heater in air with a

velocity less than 1 Ft. Per Second.

3. The heater may be bolted to the duct with the terminal housing

and flange at the top, at either side or at the bottom.

4. Several heaters may be mounted in tandem so long as proper

controls are used to limit the maximum temperature attained.

5. Installation with duct transitions in some air distribution sys-

tems, the duct heater may be considerably larger than the duct-

work and the duct area must be increased by a sheet metal tran-

sition. The slope of the transformation piece on the upstream

side of the equipment is limited to 30° as indicated in Figure 3.

On the leaving side, the slope should not be more than 45°.

6. Use moisture proof terminal cover in atmospheres bearing cor-

rosive fumes or excessive moisture.

7. Use explosion resistant heaters in explosive atmospheres and

reduce current rating to elements.

8. Gas tight design — Achieved by the use of threaded fittings

with fiber washers to attach heating elements to flange — pre

vents leakage of ducted air into terminal housing.

9. Overtemperature protection — Thermocouple fastened to the ele-

ment sheath surface and wired to a terminal block can be provid-

ed for accurate overheat protection (standard on ADHT models).

10. Flange mounting gasket — Packed separately with each duct

heater to minimize air leakage between the flange and air duct.

Refer to Table B and Figure 4.

GENERAL

Max. Outlet Air Temp. (˚F)

Air Velocity

(Ft./Sec.)

ADH

ADHT

4

800

1050

9

800

1100

16

800

1150

25

800

1200

36

800

1200

Flange Gasket

Used On

Part No.

Flange Size

ADH and ADHT

168-055429-001

11-1/8 x 5-5/8

5 kW

168-055429-002

11-1/8 x 7-5/8

10 kW

168-055429-003

11-1/8 x 9-5/8

15 kW

168-055429-004

11-1/8 x 11-5/8

20 kW

168-055429-005

11-1/8 x 13-5/8

25 kW

168-055429-006

11-1/8 x 15-5/8

30 kW

168-055429-007

11-1/8 x 17-5/8

35 kW

168-055429-008

11-1/8 x 19-5/8

40 kW

168-055429-009

11-1/8 x 21-5/8

45 kW

168-055429-010

11-1/8 x 23-5/8

50 kW

168-055429-011

11-1/8 x 27-5/8

60, 120 kW

168-055429-013

11-1/8 x 35-5/8

80, 144, 160 kW

168-055429-014

11-1/8 x 39-5/8

90, 162, 180 kW

168-055429-015

11-1/8 x 43-5/8

100 kW

168-055429-017

20 x 27-5/8

216, 240 kW

168-055429-018

20 x 33-5/8

270, 300 kW

Specifications — Table B

Flange

Mounting

Gasket

Duct Wall

2-1/2" x 1-1/4" x 3/4"

Knockouts

45˚

45˚

Max

30"

Max

30˚

Duct Heater

Air

Flow

4 Ft. Min.

4 Ft. Min.

Figure 3

Figure 4

INSTALLATION

2

Heater

Opening

Angle Iron

Duct

Duct

Metal

Strapping

Heater Opening

Chains

Figure 5