Chromalox S-RAD-2 User Manual

Chromalox, Type s-rad electric radiant heater, Pg422-2

DATE

SALES

REFERENCE

DIVISION

SECTION

Chromalox

®

(Supersedes PG422-1)

PG422-2

RAD

161-058066-001

SEPTEMBER, 2001

4

Type S-RAD

Electric Radiant Heater

© 2010 Chromalox, Inc.

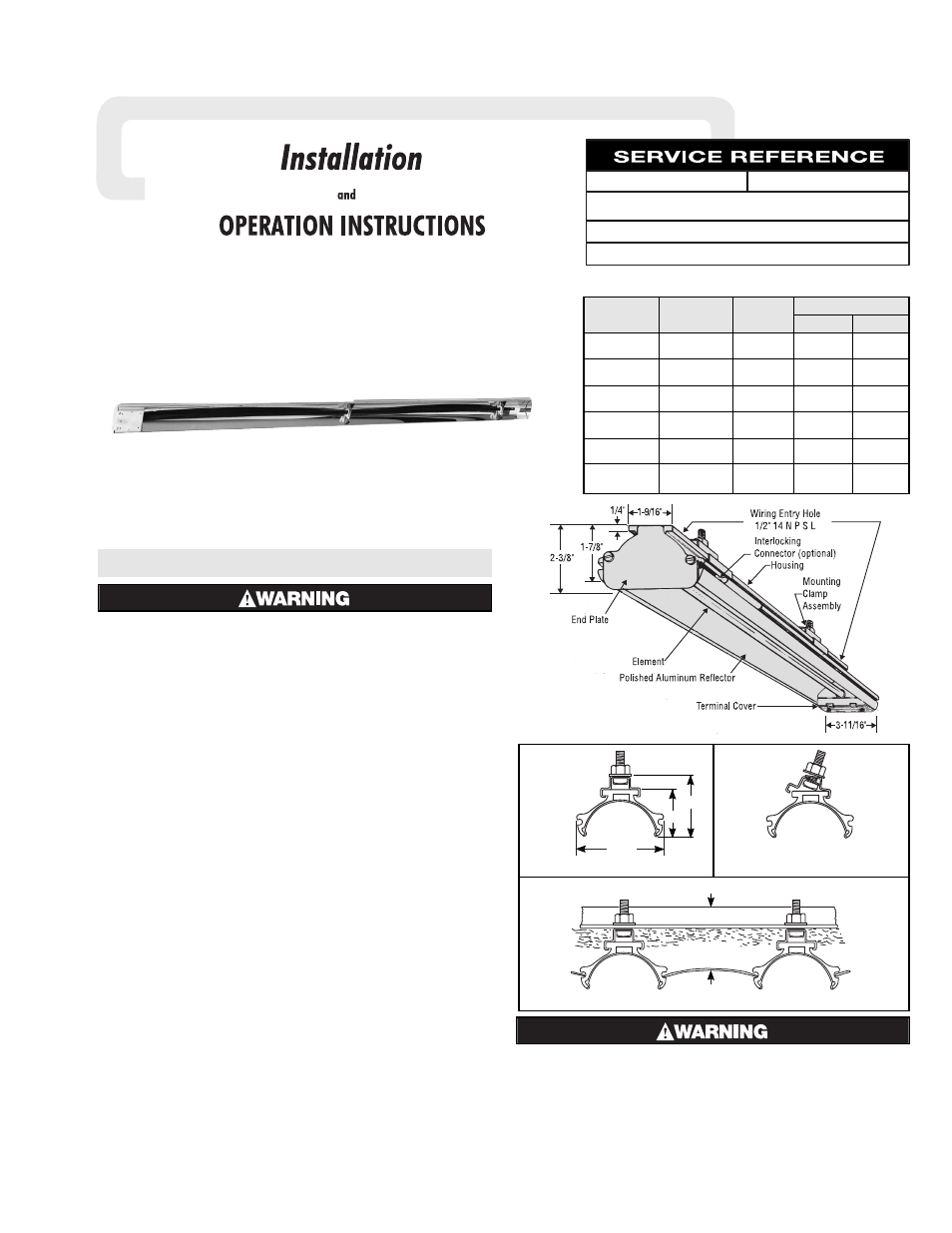

Specifications

MOUNTING

Hazard of Fire. In the case of solvents of an explo-

sive nature, ventilation air must be in sufficient vol-

ume to dilute the solvent vapor so that explosive

mixtures cannot occur. In order to comply with the

standards of safety required by the insurance com-

panies, ventilation protection and other facilities

must be in accordance with National Fire Protection

Association Bulletin No. 86, entitled “Standard for

Class A Ovens and Furnaces”. This bulletin may be

obtained from the Association at 1 Batterymarch

Park, Quincy, MA 02269.

Length (In.)

Model

Volts

kW

Overall

Heated

S-RAD-2

120 or 240

0.95

24-3/8

16-1/2

S-RAD-2V

208 or 275

S-RAD-3

120 or 240

1.3

30-5/8

22-3/4

S-RAD-3V

208 or 275

S-RAD-4V

208 or 275

2.2

46-5/8

38-5/8

S-RAD-4

240 or 480

S-RAD-5V

208 or 275

3.0

61-3/8

53-3/8

S-RAD-5

240 or 480

S-RAD-6V

208 or 275

3.75

73-3/4

65-3/4

S-RAD-6

240 or 480

S-RAD-7V

208 or 275

4.4

85-3/4

77-3/4

S-RAD-7

240 or 480

Note: Please familiarize yourself with these instructions before attempting

to install or connect this Radiant Heater.

Before Installing

1. Open carton and remove heater at the place of installation.

Mounting clamps are in parts bag in carton.

2. Check nameplate volt and watt rating against your power sup-

ply voltage and heating requirements of your installation. This

nameplate is located on one end of the heater.

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do

so could result in personal injury or property dam-

age. Heater must be installed by a qualified person

in accordance with the National Electrical Code,

NFPA 70.

1. Clamps — Heaters are mounted by means of the mounting

clamp and

3

/

8

” bolt assembly which is used as shown in Figure

2. Clamp assembly may be attached to heater by sliding over

end or by snapping over top of extruded frame section at any

point along its length (see Figure 3). For proper heater support,

the maximum distance between clamps must not exceed 48”.

On extra-long heaters, more than two clamps are furnished.

2. Mounting Holes — When heaters are mounted adjacent to

each other in the same plane, note that distance between mount-

ing holes on framing to support heaters will be 3

11

/

16

” minimum.

When heaters are not in the same plane, i.e., set at an angle to

one another, distance between mounting holes in framing will

be either greater or less than 3

11

/

16

”.

3. Framing — Where an extensive installation is being made, the

use of continuous slot metal framing manufactured by several

concerns will be of assistance in saving time and money. The

framing is reusable.

4. Reflector Spacer Sheets — Where heaters are not mounted

side by side (see Figure 4), reflector spacer sheets can be used

between heaters. These reflector spacer sheets and companion

reflectors consisting of an extruded aluminum housing with

reflector sheet and mounting clamps are available. Check factory.

5. Insulation — Where unusually high work temperatures are

encountered, it may be desirable to insulate backs of heaters

with high-temperature fibrous insulation. A suggested method

of accomplishing this is indicated in Figure 4.

6. Ventilation — Where solvents, water, etc. are being evaporat-

ed from work in process, it is necessary to provide substantial

quantities of ventilation air to carry away the resulting vapors.

Mounting Frame

Reflector

Spacer Sheet

Insulation

Figure 4

Figure 1 — Heater Parts and Dimensions

2 / "

15 16

2 / "

3 8

3 / "

11 16

Figure 3

Figure 2