Servo electrical installation – Dynon Avionics EFIS-D10A Installation Guide User Manual

Page 44

Autopilot Installation and Configuration

6-4

EFIS-D10A

Installation

Guide

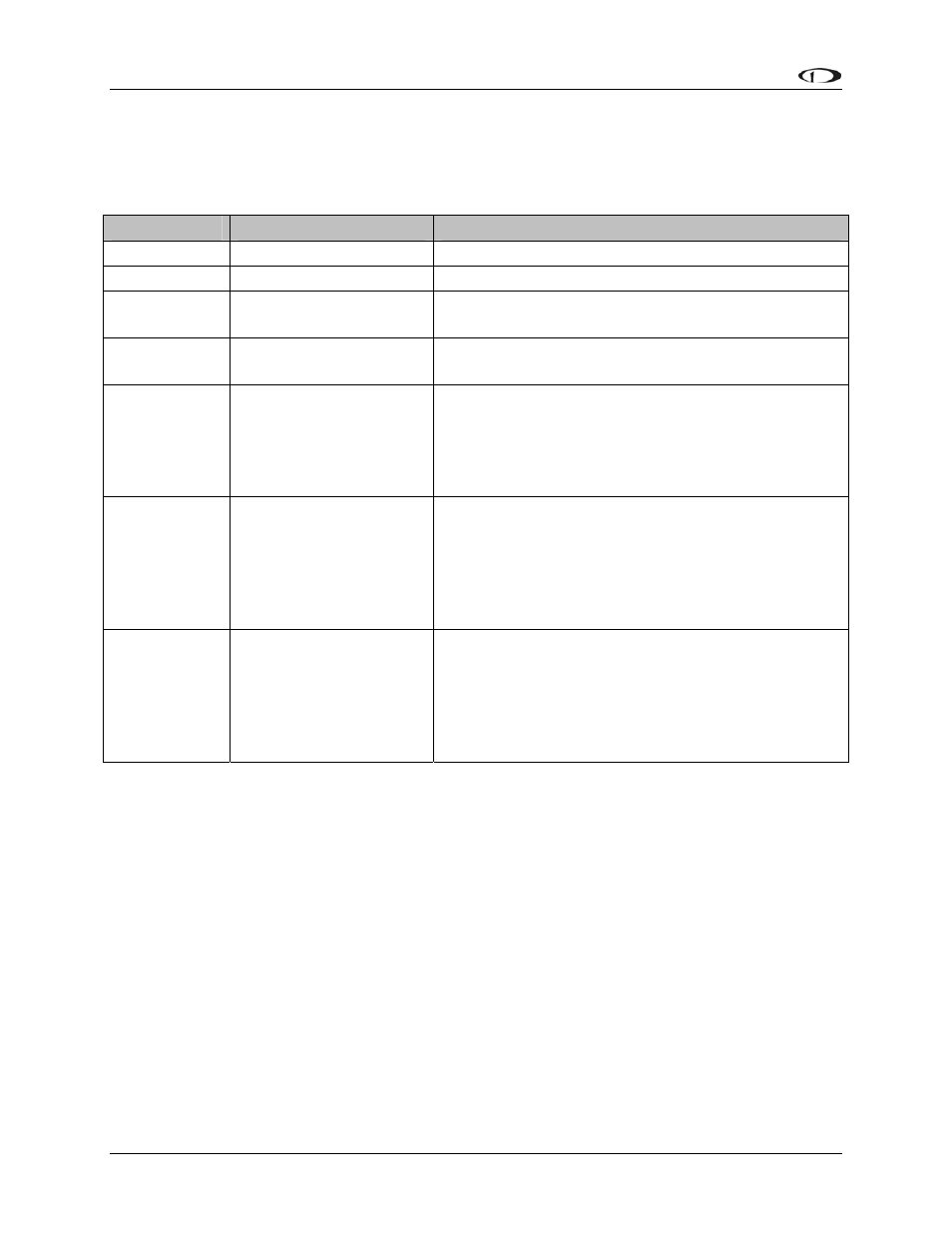

SERVO ELECTRICAL INSTALLATION

Dynon Avionics’ servos are supplied with 7 un-terminated wires, each about 8” in length. It is

the responsibility of the installer to decide on connectors and associated wiring. The 7 wires have

the following colors and functions:

Color

Function

Notes

Red

Power

10-30 volts DC. Each servo draws up to 2 amps

Black

Aircraft Ground

Each servo draws up to 2 amps

Green

Dynon Smart Avionics

Bus [DSAB] “A”

Connected in parallel with other DSAB devices

(Green wire on all Dynon-supplied wiring harnesses)

Blue

Dynon Smart Avionics

Bus [DSAB] “B”

Connected in parallel with other DSAB devices

(Blue wire on all Dynon-supplied wiring harnesses)

Yellow

AP Disengage/Control

Wheel Steering (CWS)

Button

Connected through a normally-open pushbutton

switch to Ground (disengages AP when button is

pushed). If two servos are installed, the yellow wire

from each servo is connected in parallel to a single

pushbutton.

White/Green

Reserved for

compatibility with

Dynon “Next

Generation” products

DO NOT CUT! During servo installation, Dynon

recommends that this be routed to the cockpit panel

(include sufficient slack behind the panel) if you

want to preserve compatibility of the servo with

Dynon’s “Next Generation” technology. This wire is

not used with the EFIS-D10A.

White/Blue

Reserved for

compatibility with

Dynon “Next

Generation” products

DO NOT CUT! During servo installation, Dynon

recommends that this be routed to the cockpit panel

(include sufficient slack behind the panel) if you

want to preserve compatibility of the servo with

Dynon’s “Next Generation” technology. This wire is

not used with the EFIS-D10A.

Circuit Breaker/Switch: We recommend that electrical power for the all servos be

protected with an appropriately sized circuit breaker or switch that is accessible to the

pilot while in flight.

Wire Sizing: While it is beyond the scope of this installation guide to advise on specific

types of wiring for a particular aircraft, choice of wiring should be sized to 1) minimize

voltage drop over the length of the particular wiring run, and 2) conduct the amount of

current required by the subsystem without the wiring becoming warm to the touch.

Wiring Installation: Care should be taken such that aircraft wiring is not subjected to

chafing, excessive flexing, or connections / junctions subjected to excessive vibration

which may cause the connection/junction to fail or short-circuit. If the White/Green and

White/Blue wires are extended to the cockpit panel, leave sufficient slack behind the

panel for connection anywhere behind the panel. If the White/Green and White/Blue

wires are not extended to the cockpit panel, as with other unused wires, DO NOT CUT

the wires, but rather insulate the ends of the wires (electrical tape, heatshrink tubing),

bundle, and secure the unused wire.