En english, Sanding cuts and sandpaper – Clarke 07104A User Manual

Page 13

EN

ENGLISH

Clarke

®

American Sanders

Operator's Manual (EN) - Floorcrafter

- 13 -

Sanding Cuts and Sandpaper

Initial Cut

The purpose of the initial cut is to remove old finish

and gross imperfections on the floor surface. The

sanding equipment should be adjusted to heavy

sanding pressure setting and a coarse abrasive

belt should be used. If the surface is severely

damaged by deep scratches, preexisting dwell

marks, uneven planks, etc., it may be necessary

to sand across or diagonally to the grain to restore

evenness to the surface. If these conditions are

not present, the initial cut should be done in the

direction of the grain.

If glazing, loading, or burning takes place immedi-

ately into an initial cut, select a coarser abrasive.

If this should occur during an initial cut, the

abrasive has dulled and must be replaced.

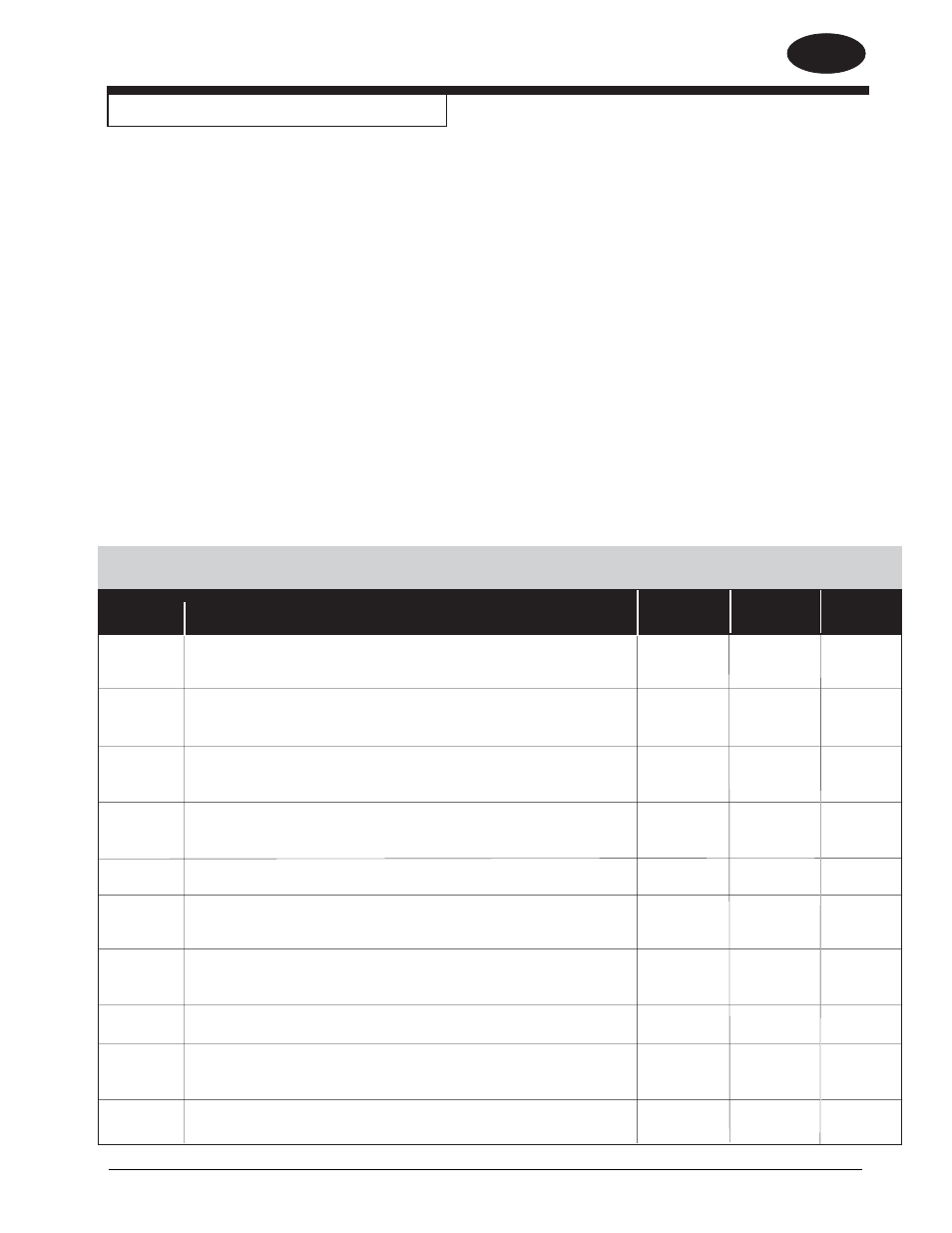

Grain

Use

16 grit

For removing gross imperfections and restore evenness

-

945844

-

to old flooring. To remove build-up of paints and varnishes.

36 grit

For first sanding of new flooring (maple, oak). For removing

-

945842 945901

minor imperfections and finishes from old flooring.

40 grit

For first sanding of new flooring (oak, walnut). For removing

-

945841 945902

minor imperfections and finishes from old flooring.

50 grit

For first sanding of new flooring (cedar, pine, fir)

-

945840 945903

For cleanup of 16 grit.

60 grit

For cleanup from initial cut 36 - 40 grit.

945839

-

945904

80 grit

For final sanding of certain hardwoods. For cleanup

945838

-

945905

of initial cuts (50 grit).

100 grit

For final sanding of certain hardwoods where a smooth

945837

-

945909

surface is desired.

120 grit

For final sanding of certain conifers.

945836

-

945910

150 grit

For final sanding of certain conifers where a smooth

945835

-

945911

surface is desired.

180 grit

For surface roughing between coats of finish.

945834

-

-

Abrasive Belts

Note: All part numbers listed are for a carton of 10 belts

Aluminum

Silicon Ceramic

Oxide

Carbide Alum.Oxide

Final Cuts

The purpose of a finishing cut is to remove the

scratches produced during the initial cut. Use a

fine (60 - 80 grit) grain abrasive and a reduced

sanding pressure setting.

If the surface remains rough after a finishing cut, it

may be necessary to use an even finer grain of

abrasive (80 - 100 grit). Care should be taken in

selecting the grit size of the abrasive. A very fine

grain will close the pores on a wood floor making

admission of a stain difficult.

If glazing or burning should occur immediately into

a finishing cut, reduce the sanding pressure. If it

should occur during a finishing cut, the abrasive

has dulled and must be replaced.