Parts replacement–friction facing (all models), Parts replacement–housing bearing, model fmce 625 – Nexen FMCE-875 801474 User Manual

Page 8

8

FORM NO. L-20168-D-1112

PARTS REPLACEMENT–FRICTION FACING (ALL MODELS)

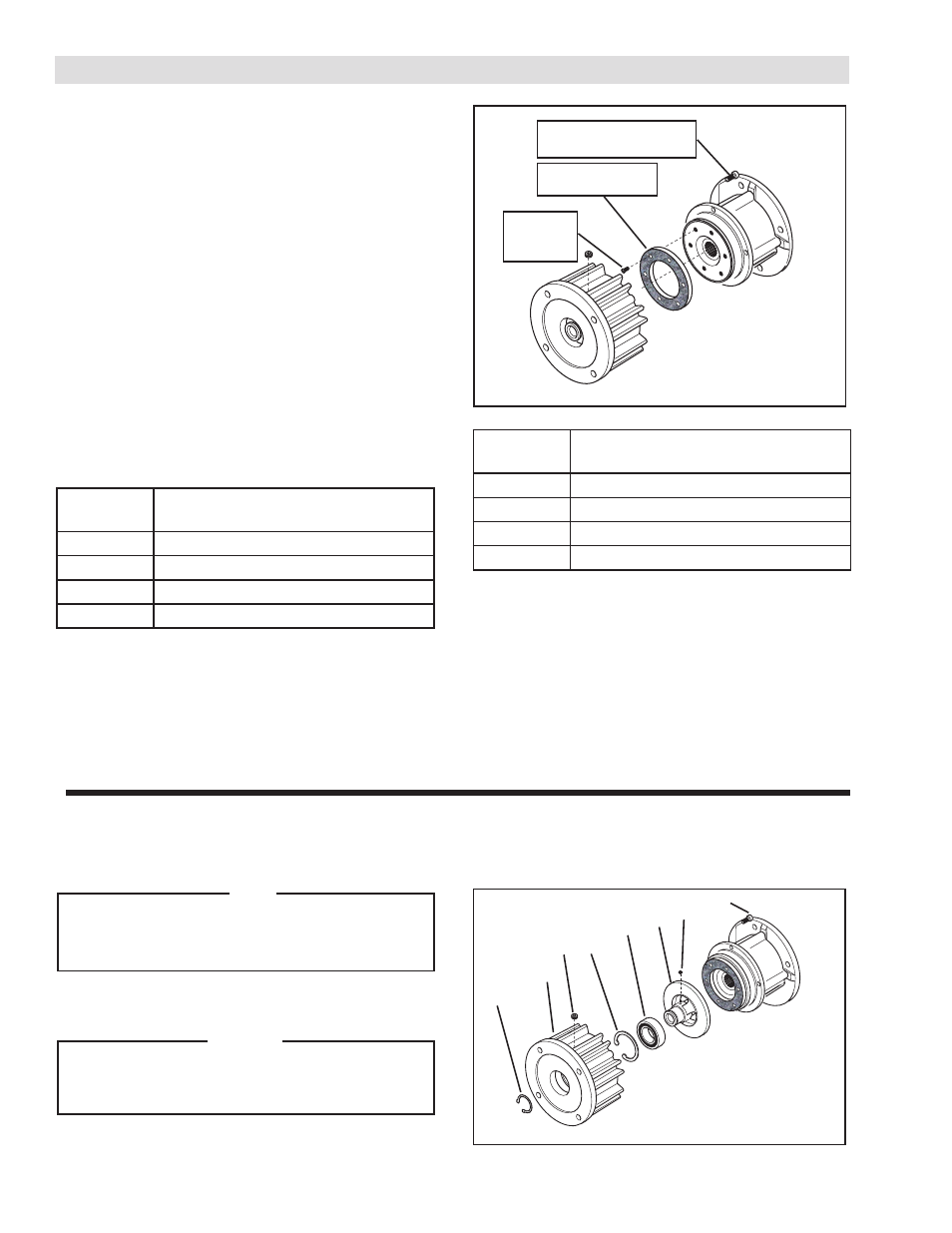

1. Remove the four Socket Head Cap Screws (Item 12)

and separate the two halves of the FMCE (See Figure

6).

2. Remove the six old Flat Head Screws (Item 7) and the

old Friction Facing (Item 8) (See Figure 6).

3. Install the new Friction Facing (Item 8) and new Flat

Head Screws (Item 7) (See Figure 6).

4. Tighten the six new Flat Head Screws to the

recommended torque (See Table 3).

5. Apply a drop of Loctite

242 to the threads of the Socket

Head Cap Screws (Item 12) (See Figure 6).

6. Reinstall and tighten the four Socket Head Cap Screws

(Item 12) to the recommended torque (See Table 4).

FIGURE 6

Socket Head Cap Screw

(Item 12)

Friction Facing

(Item 8)

Flat Head

Screw

(Item 7)

TABLE 4

TABLE 3

PARTS REPLACEMENT–HOUSING BEARING, MODEL FMCE 625

NOTE

If an Input Unit is installed on the FMCE, it must be

removed before servicing the FMCE. Remove the Plug

(Item 27) and loosen the Set Screw (Item 26) to release

the FMCE from the Input Unit (See Figure 7).

1. Remove the four Socket Head Cap Screws (Item 12) and

separate the two halves of the FMCE (See Figure 7).

WARNING

Special attention should be exercised when working

with retaining rings. Always wear safety goggles when

working with spring or tension loaded fasteners or

devices.

2. Remove the Retaining Ring (Item 6) (See Figure 7).

6

1

4

2

3

12

FIGURE 7

27

26

Model

Recommended Tightening Torque

for (Item 7)

FMCE 625

26 In. Lbs. [2.9 Nm]

FMCE 875

26 In. Lbs. [2.9 Nm]

FMCE 1125

71 In. Lbs. [8.0 Nm]

FMCE 1375

71 In. Lbs. [8.0 Nm]

Model

Recommended Tightening Torque

for (Item 10)

FMCE 625

157 In. Lbs. [17.7 Nm]

FMCE 875

266 In. Lbs. [30.0 Nm]

FMCE 1125

266 In. Lbs. [30.0 Nm]

FMCE 1375

594 In. Lbs. [55.5 Nm]