Air connections, Lubrication, Lubricator drip rate settings – Nexen FMCE-875 801474 User Manual

Page 6

6

FORM NO. L-20168-D-1112

8. Secure the FMCE Housing (Item 1) to the Female Pilot

(Item 13) using Socket Head Caps Screws (Item 24). Then,

alternately and evenly tighten the Socket Head Cap Screws

to the recommended torque (See Figure 4 and Table 2).

9. Align the Set Screw (Item 26) in the Drive Disc (Item 4) with

the hole in the FMCE Housing (See Figure 4).

10. Tighten the Set Screw (Item 26); then, install the Plug (Item

27) (See Figure 4).

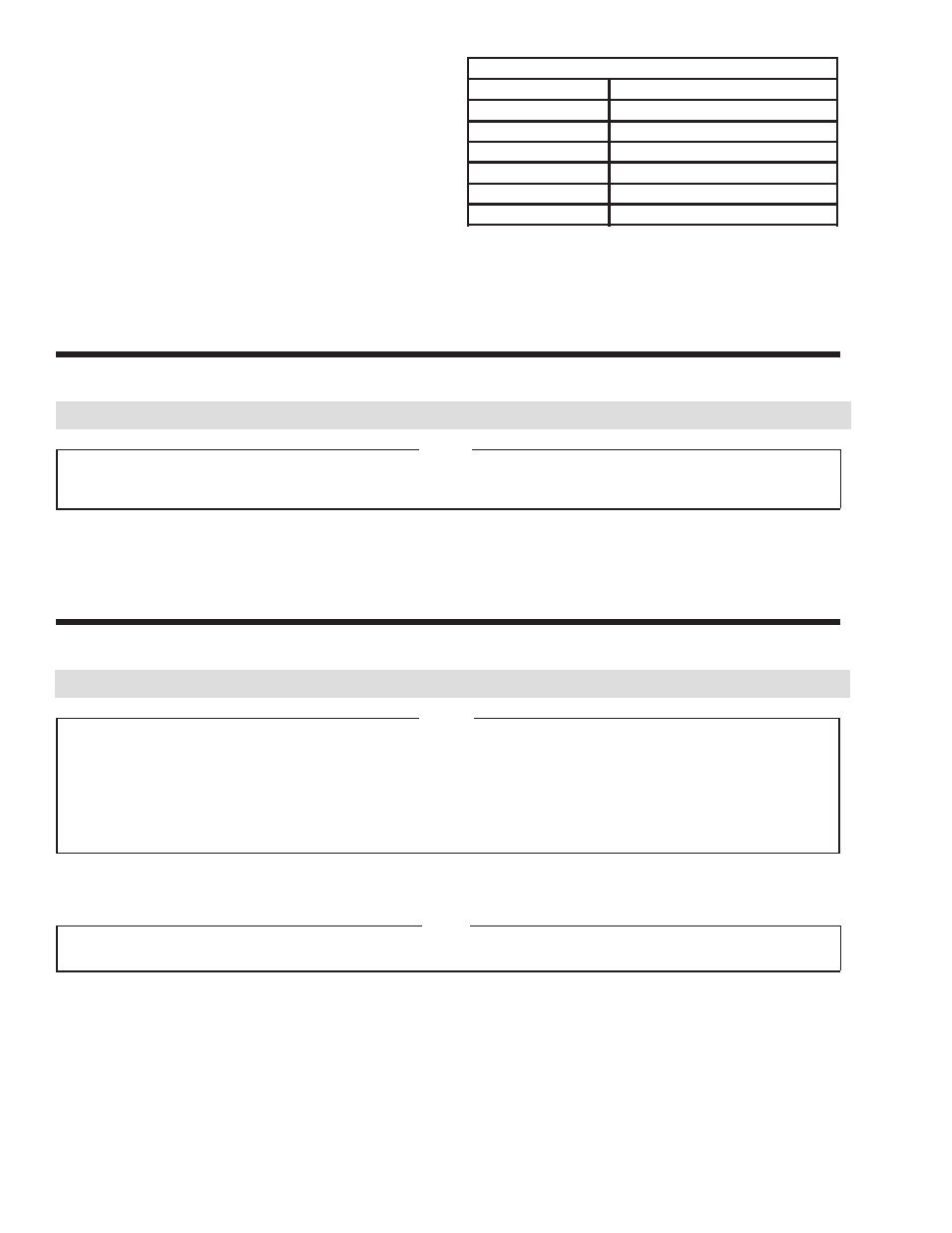

RECOMMENDED TIGHTENING TORQUE

MODEL

TIGHTENING TORQUE

FMCE 875 (Item 24)

157 In. Lbs. [17.7 N m]

FMCE 1125 (Item 24)

267 In. Lbs. [30.2 N m]

FMCE 1375 (Item 24)

580 In. Lbs. [65.0 N m]

FMCE 875 (Item 29)

580 In. Lbs. [65.0 N m]

FMCE 1125 (Item 29)

1425 In. Lbs. [159.6 N m]

FMCE 1375 (Item 29)

1425 In. Lbs. [159.6 N m]

TABLE 2

AIR CONNECTIONS

NOTE

For quick response, Nexen recommends a quick exhaust valve and short air lines between the Control Valve and the FMCE.

Align the air inlet port to a down position to allow condensation to drain out of the air chamber of the FMCE.

LUBRICATION

NOTE

Pneumatically actuated devices require clean, pressure regulated, and lubricated air for maximum performance and long

life. The most effective and economical way to lubricate the FMCE is with an Air Line Lubricator, which injects oil into the

pressurized air, forcing an oil mist into the air chamber.

Locate the lubricator above and within ten feet of the FMCE, and use a low viscosity oil such as SAE-10.

Synthetic lubricants are not recommended.

LUBRICATOR DRIP RATE SETTINGS

NOTE

These settings are for Nexen supplied lubricators. If you are not using a Nexen lubricator, calibration must replicate the

following procedure.

1. Close and disconnect the air line from the unit.

2. Turn the Lubricator Adjustment Knob clockwise three com-

plete turns.

3. Open the air line.

4. Close the air line to the unit when a drop of oil forms in the

Lubricator Sight Gage.

5. Connect the air line to the unit.

6. Turn the Lubricator Adjustment Knob counterclockwise until

closed.

7. Turn the Lubricator Adjustment Knob clockwise one-third

turn.

8. Open the air line to the unit.