Nexen FMCE-875 801474 User Manual

Page 10

10

FORM NO. L-20168-D-1112

RECOMMENDED TIGHTENING TORQUE

MODEL

TIGHTENING TORQUE

FMCE 875 (Item 24)

157 In. Lbs. [17.7 N m]

FMCE 1125 (Item 24)

266 In. Lbs. [30.0 N m]

FMCE 1375 (Item 24)

580 In. Lbs. [65.0 N m]

TABLE 5

NOTE

Do not reuse the bearing. Applying force to the inner

bearing race to remove a bearing held by the outer race

causes damage to the bearing.

6. Clean the bearing bore of the Female Pilot (Item 13) with

fresh safety solvent, making sure all old Loctite

®

residue is

removed (See Figure 8).

7. Apply an adequate amount of Loctite

®

680 to evenly

coat the outer race of the new Bearing (Item 2) (See Figure

8).

8. Carefully align the outer race of the new Bearing (Item 2)

with the bore of the Female Pilot (Item 13) (See Figure 8).

9. Supporting the Female Pilot (Item 13) and pressing on the

outer race of the new Bearing (Item 2), press the new Bearing

into the Female Pilot (See Figure 8).

10. Reinstall the Retaining Ring (Item 3) (See Figure 8).

11. Support the inner race of the new Bearing (Item 2) and press

the Drive Disc (Item 4) into the new Bearing and Female Pilot

(Item 13) (See Figure 8).

12. Reinstall the Retaining Ring (Item 6) (See Figure 8).

NOTE

If you are replacing all the Bearings and O-ring Seals

in the FMCE, proceed to PARTS REPLACEMENT–

BE A R I N G S A N D O - R I N G SE A L S ; o t h e r w i s e ,

proceed with the next step.

13. Apply a drop of Loctite

®

242 to the threads of the Socket

Head Cap Screws (Item 24) (See Figure 8).

14. Slide the Female Pilot (Item 13), Bearing (Item 2), and Drive

Disc (Item 4) into the FMCE and reinstall the four Socket

Head Cap Screws (Item 24) (See Figure 8).

15. Alternately and evenly tighten the four Socket Head Cap

Screws (Item 24) to the recommended torque (See Figure

13 and Table 5).

PARTS REPLACEMENT–BEARINGS AND O-RING SEALS (ALL MODELS)

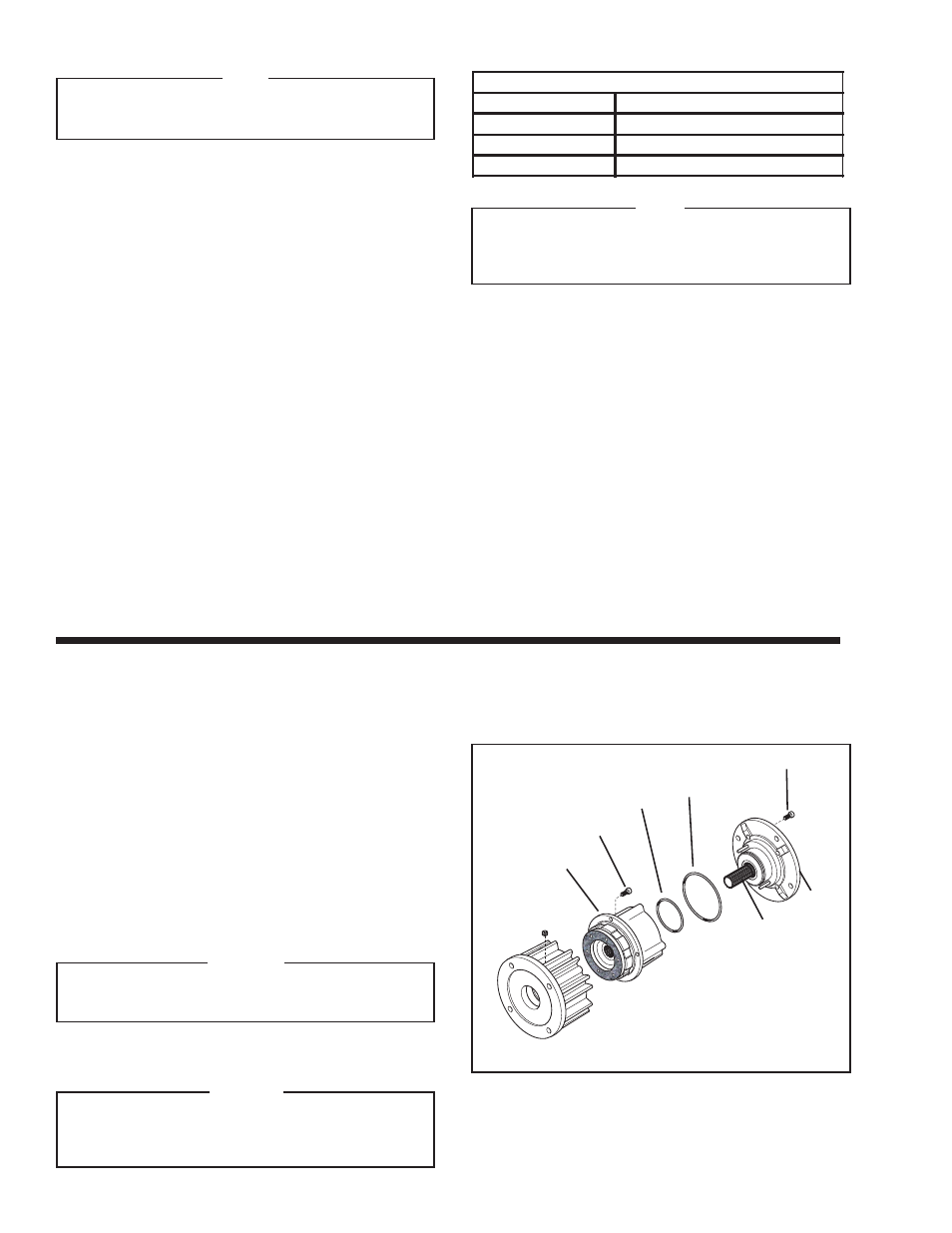

1. Remove the four Socket Head Cap Screws (Item 12) and

separate the two halves of the FMCE (See Figure 9).

2. Remove the four Socket Head Cap Screws (Item 12) securing

the Male Pilot (Item 19) to the Air Chamber (Item 11) (See

Figure 9).

3. Remove the Male Pilot (Item 19) and Stub Shaft (Item 22)

from the Air Chamber (Item 11) (See Figure 9).

4. Remove and discard the old O-ring Seals (Items 20 and 21)

(See Figure 9).

WARNING

The Piston (Item 15) is spring loaded. Always wear safety

goggles when working with spring or tension loaded

fasteners or devices.

5. Using a "C" clamp, compress the Piston (Item 15) into the

Air Chamber (Item 11) (See Figure 10).

WARNING

Special attention should be exercised when working

with retaining rings. Always wear safety goggles when

working with spring or tension loaded fasteners or

devices.

22

19

12

21

20

12

FIGURE 9

11