Installation, Fmce 625 mounted on the shaft end of a motor – Nexen FMCE-875 801474 User Manual

Page 4

4

FORM NO. L-20168-D-1112

INSTALLATION

NOTE

The following sections are arranged by model. Verify that you are in the correct section for your model.

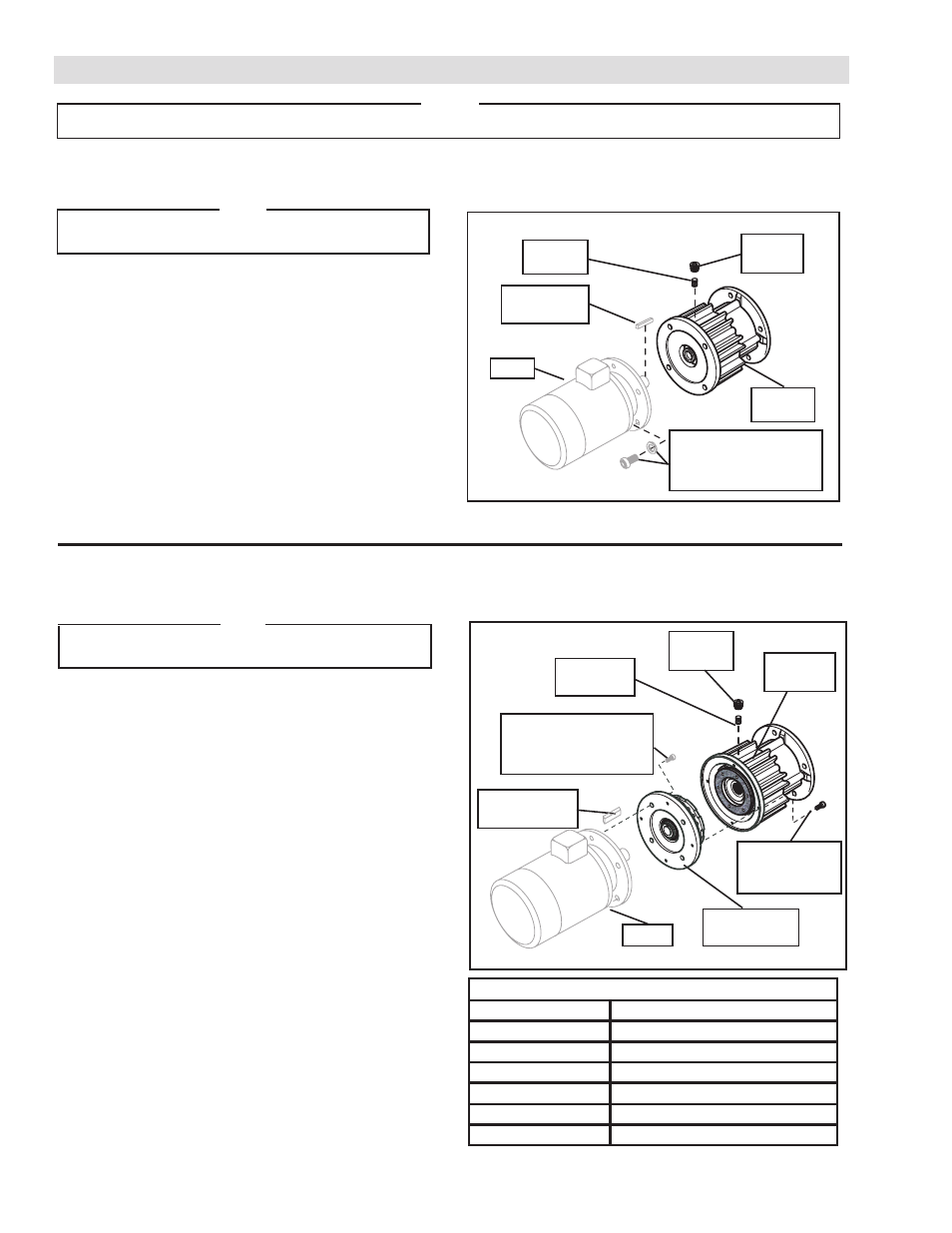

FMCE 625 MOUNTED ON THE SHAFT END OF A MOTOR

NOTE

FIGURE 1

Socket Head

Cap Screw (Item 29)

and

Lock Washer (Item 30)

Motor

FMCE

Housing

Set Screw

(Item 26)

Plug

(Item 27)

FMCE 875, 1125, AND 1375 MOUNTED ON THE SHAFT END OF A MOTOR

NOTE

Align the air inlet on the FMCE, to a down position to allow

condensation to drain out of the air chamber.

1. Insert the customer supplied key into the motor shaft keyway

(See Figure 2).

2. Remove the Socket Head Cap Screws (Item 24) and

the Female Pilot (Item 13); then, secure the Female

Pilot to the motor face using Nexen supplied Socket

Head Cap Screws (Item 29) and Lock Washers

(Item 30) (See Figure 2).

3. Alternately and evenly tighten the Socket Head Cap Screws

(Item 29) to the recommended torque (See Table 1).

4. Slide the Female Pilot (Item 13) onto the motor shaft (See

Figure 2).

5. Apply a drop of Loctite

®

242 to the threads of the Socket

Head Cap Screws (Item 24) (See Figure 2).

6. Secure the FMCE Housing (Item 1) to the Female Pilot

(Item 13) using Socket Head Cap Screws (Item 24); then,

alternately and evenly tighten the Socket Head Cap Screws

to the recommended torque (See Figure 2 and Table 1).

7. Align the Set Screw (Item 26) in the Drive Disc (Item 4) with

the hole in the FMCE Housing (See Figure 2).

8. Tighten the Set Screw (Item 26); then, install the Plug (Item

27) (See Figure 2).

Motor

Customer

supplied key

Set Screw

(Item 26)

Plug

(Item 27)

Socket Head

Cap Screws

(Item 24)

Female Pilot

(Item 13)

FMCE

Housing

FIGURE 2

RECOMMENDED TIGHTENING TORQUE

MODEL

TIGHTENING TORQUE

FMCE 875 (Item 24)

157 In. Lbs. [17.7 N m]

FMCE 1125 (Item 24)

267 In. Lbs. [30.2 N m]

FMCE 1375 (Item 24)

580 In. Lbs. [65.0 N m]

FMCE 875 (Item 29)

580 In. Lbs. [65.0 N m]

FMCE 1125 (Item 29)

1425 In. Lbs. [159.6 N m]

FMCE 1375 (Item 29)

1425 In. Lbs. [159.6 N m]

Align the air inlet on the FMCE, to a down position to allow

condensation to drain out of the air chamber.

1. Insert the customer supplied key into the motor shaft keyway

(See Figure 1).

2. Slide the FMCE onto the motor shaft and secure it to the

motor using Nexen supplied Socket Head Cap Screws (Item

29) and Lock Washers (Item 30) (See Figure 1).

3. Alternately and evenly tighten the Socket Head Cap Screws

(Item 29) to 580 In. Lbs. [65.0 N•m] torque.

4. Align the Set Screw (Item 26) in the Drive Disc (Item 4) with

the hole in the FMCE Housing (See Figure 1).

5. Tighten the Set Screw (Item 26); then, install the Plug (Item

27) (See Figure 1).

TABLE 1

Customer

supplied key

Socket Head

Cap Screw (Item 29)

and

Lock Washer (Item 30)