Nexen RPS4014G-B0192T/023-EP2U 966725 User Manual

Page 9

9

FORM NO. L-21198-A-1204

DISENGAGING THE ROLLER PINION

1.

Remove the load that the RPS system is transferring.

2.

Cut the power source, ensuring that no torque is

applied to the roller pinion.

3.

Remove preload (Refer to APPLYING PRELOAD

section).

4.

Gradually loosen the mechanical lock bolts in the

same order they were tightened (Refer to Figure 5).

NOTE: Inspect all lock bolts and replace any that show

excessive wear.

DANGER

Failure to properly support the load before

disengaging the RPS system could cause

serious harm to operators or equipment.

LUBRICATION

Nexen recommends lubricating the RPS rack to ensure smooth operation and long service life.

1.

Lubricate the rack by applying a synthetic oil based grease to the pins of the roller pinion. Then glide the roller

pinion back and forth over the meter segment of rack five times to distribute the grease.

NOTE: Use THK AFA or equivalent grease. Grease must meet the following Kinematic Viscosity Levels: CST@40C -

25; CST@100C - 5.

2.

Repeat step one for each meter of rack

This will distribute lubrication along the rack teeth in all contact areas.

NOTE: Nexen recommends lubricating the rack a minimum of twice a year. Customer may need to re-lubricate

more frequently based on environmental conditions and observable tooth wear.

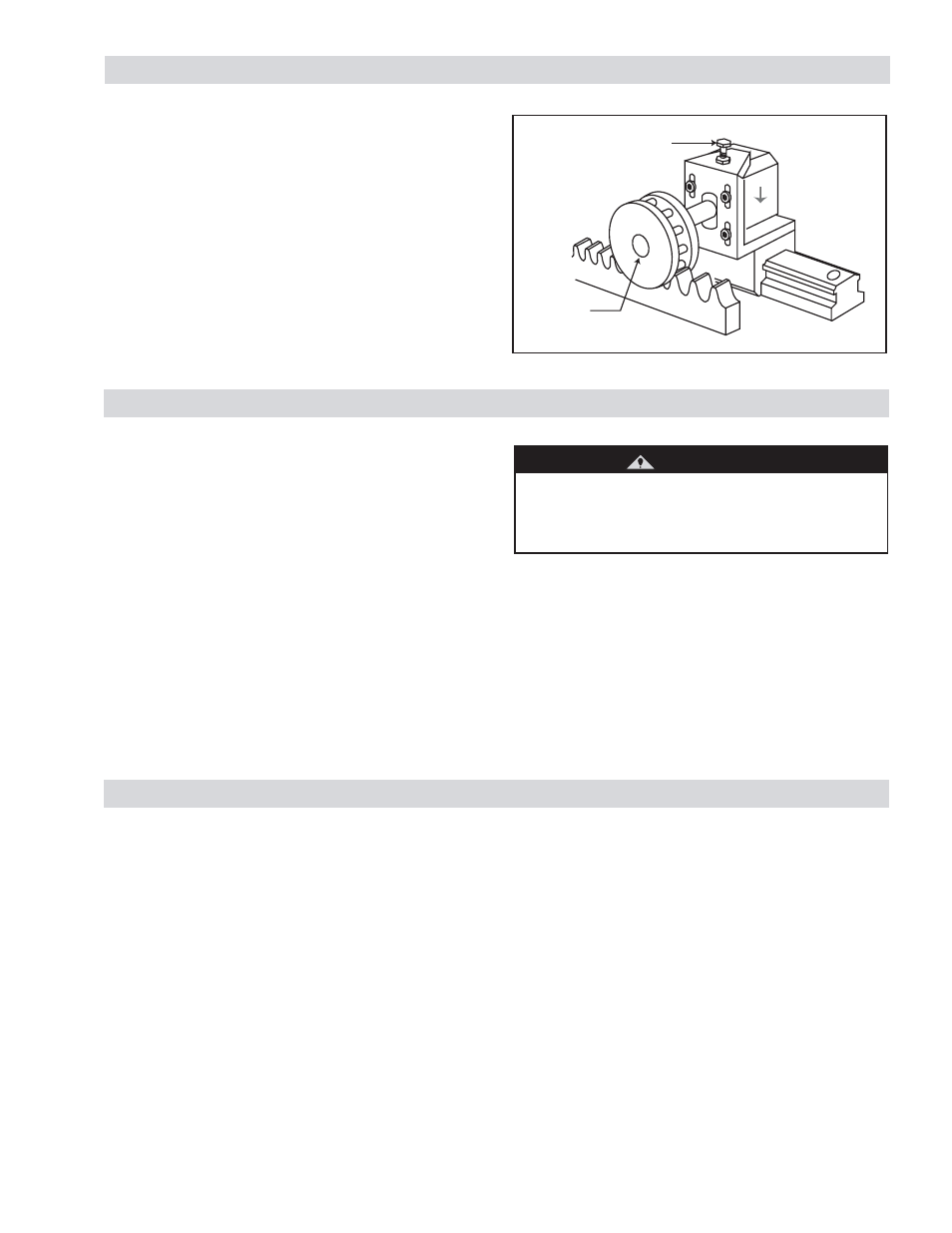

Push

Screw

Preload

Figure 9

APPLYING PRELOAD

To ensure optimal meshing of the roller pins with the rack

teeth, the shaft must be preloaded to 0.01 mm [0.0004

in] beyond full engagement.

NOTE: Do not apply excessive preload. Preloading

beyond 0.01 mm will decrease product life and increase

noise and vibration.

Refer to Figure 9 for suggested preload method.

NOTE: There will be no rotational movement of the pinion

when the assembly is stationary if the system is

Preloaded properly.