Nexen RPS4014G-B0192T/023-EP2U 966725 User Manual

Page 7

7

FORM NO. L-21198-A-1204

ROLLER PINION SETUP

NOTE: Refer to sales drawings for shaft details.

NOTE: Refer PROPER SYSTEM ALIGNMENT and Fig-

ures 6 & 7 for Roller Pinion mounting requirements.

NOTE: Pinion should be mounted as close to a bearing

as possible for optimal performance.

1.

Remove any debris from the shaft, roller pinion and

mechanical lock.

NOTE: The RPS is shipped with the mechanical lock

already inserted into the roller pinion bore.

2.

If the mechanical lock has been removed, insert the

cylindrical wedge into the roller pinion bore until it

rests against wall of the roller pinon.

3.

Insert the inner race of the mechanical lock into the

roller pinon bore with one screw hole in the 12 o-

clock position (See Figure 5).

NOTE: Ensure that the slots in the two components

that make up the mechanical lock are not aligned.

4.

Insert the shaft into the bore.

5.

Insert the lock bolts into the through holes

(threaded holes are for mechanical lock removal).

6.

Hand tighten the lock bolts.

7.

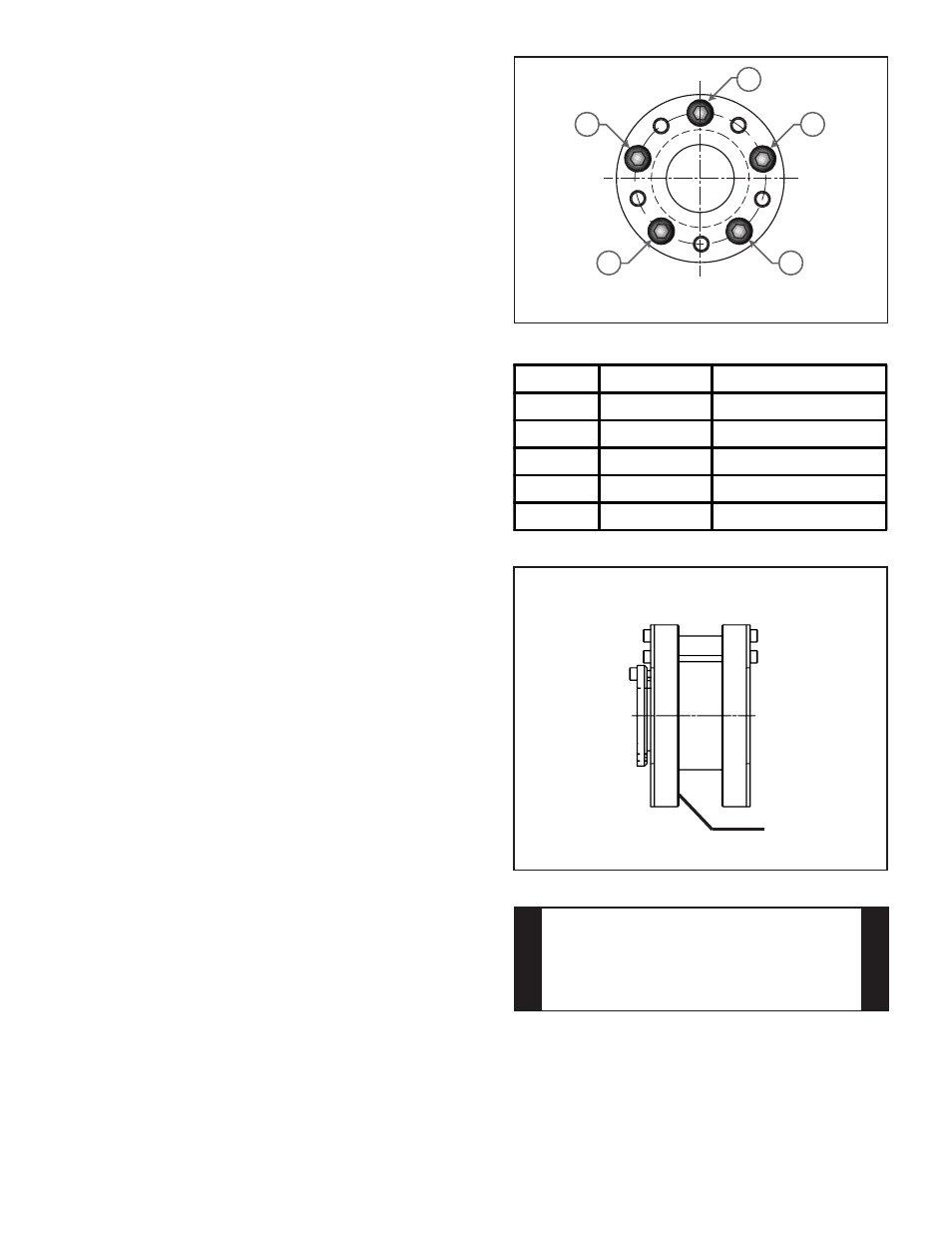

Equally tighten the lock bolts with 1/4 of the

recommended tightening torque. Start tightening at

the top bolt and alternate back and forth across the

face in a star pattern until all five bolts are

tightened (Refer to Figure 5 and Table 3).

8.

Finally, tighten the lock bolts at the predetermined

torque using a torque wrench.

Progressive tightening of the lock bolts is important

to prevent any misalignment of components while

installing the mechanical lock.

NOTE: Runout is minimized if a Dial Indicator is used

as the lock bolts are tightened. Place the contact tip of

the Dial Indicator on a smooth surface to measure

runout (See Figure 6). Runout on this surface must be

± 0.13 mm [±0.005 in] TIR when lock bolts are tightened.

NOTE: Allow pinion to travel along the rack, making

sure the sides of the rack do not contact the sides of

the pinion.

1

4

3

5

2

Figure 5

Mechanical Lock Front Face

Model

Bolt Type

Tightening Torque

RPS16

M4

3.5 Nm [30.98 in-lb]

RPS20

M5

7.0 Nm [61.96 in-lb]

RPS25

M6

12.0 Nm [106.21 in-lb]

RSP32

M6

12.0 Nm [106.21 in-lb]

RPS40

M6

12.0 Nm [106.21 in-lb]

Table 3

CAUTION

Preload must be applied before putting

Preload must be applied before putting

Preload must be applied before putting

Preload must be applied before putting

Preload must be applied before putting

your system into operation. Refer to

your system into operation. Refer to

your system into operation. Refer to

your system into operation. Refer to

your system into operation. Refer to

APPL

APPL

APPL

APPL

APPLYI

YI

YI

YI

YI N

N

N

N

N G PR

G PR

G PR

G PR

G PR E

E

E

E

E L

L

L

L

LO

O

O

O

OAD to properly set

AD to properly set

AD to properly set

AD to properly set

AD to properly set

preload for your R

preload for your R

preload for your R

preload for your R

preload for your RPS system.

PS system.

PS system.

PS system.

PS system.

Figure 6

Measure runout

on pinion face