Installation, Rack mounting dimensions – Nexen RPS4014G-B0192T/023-EP2U 966725 User Manual

Page 4

FORM NO. L-21198-A-1204

4

Rack

Model

rack

length

A

B

C

D

E

F

G

H

J

K

L

Through

Hole

Tapped Hole

Thread Depth

RPS16

half rack

80

[3.15]

32 [1.26]

24 [0.94]

8

[0.31]

24

[0.94]

8

[0.31]

9

[0.35]

M6

12

[0.47]

M8

M6 x 50

9

[0.35]

M8

full rack

32 [1.26]

24 [0.94]

RPS20

half rack

80

[3.15]

20 [0.79]

10 [0.39]

10

[0.39]

30

[1.18]

10

[0.39]

11

[0.43]

M8

16

[0.63]

M10 M6 x 60

11

[0.43]

M10

full rack

40 [1.57]

30 [1.18]

RPS25

half rack

100

[3.94]

100 [3.94] 62.5 [2.46] 37.5

[1.48]

36

[1.42]

12

[0.47]

14

[0.55]

M10

20

[0.79]

M12 M10 x 75

14

[0.55]

M12

full rack

100 [3.94] 62.5 [2.46]

RPS32

half rack

100

[3.94]

112 [4.41]

56 [2.20]

56

[2.20]

44

[1.73]

16

[0.63]

14

[0.55]

M10

20

[0.79]

M12 M10 x 95

14

[0.55]

M12

full rack

92 [3.62]

36 [1.41]

RSP40

half rack

160

[6.30]

40 [1.57]

20 [0.79]

20

[0.79]

54

[2.13]

21

[0.83]

14

[0.55]

M10

20

[0.79]

M12 M10 x 95

18

[0.71]

M16

full rack

40 [1.57]

20 [0.79]

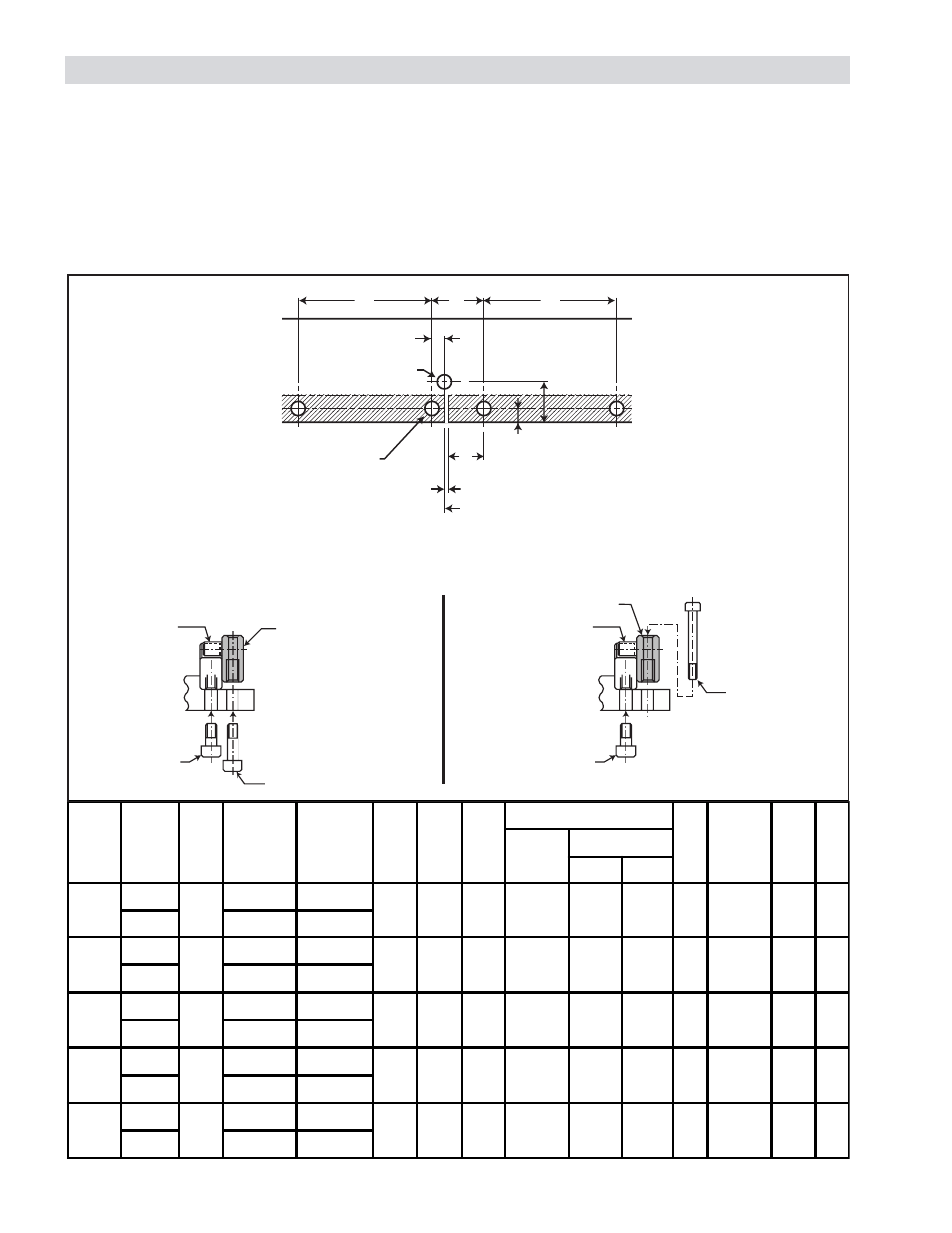

RACK MOUNTING DIMENSIONS

A

B

C

A

D

E

F

E

F

K

First Rack

Second Rack

clearance of 0.1 ~ 0.2mm

reference end surface of first rack

G*

Connecting Tool

Mounting Hole

Rack

Mounting

Hole

L

H

Rack

Mounting

Bolt

Alignment Tool

Mounting Bolt

Alignment Tool

Rack

*G

Tapped Hole Mounting of Connecting Tool

*G

Through Hole Mounting of Connecting Tool

L

J

Rack

Mounting

Bolt

Alignment Tool

Mounting Bolt

Alignment Tool

Rack

INSTALLATION

The mounting surface for both the rack and the guiding system must be parallel within the specifications shown in the

PROPER SYSTEM ALIGNMENT section. This parallelism requirement is best achieved by machining a common bed for

both the guiding system and rack in the same operation. (Refer to PROPER SYSTEM ALIGNMENT and Figures 7 & 8

for Possible Mounting Configurations.)

The system operates best when kept free from debris. Nexen recommends orienting the rack so it minimizes debris from

collecting on the teeth.

Figure 1