General rps design guidelines – Nexen HGP25 969053 User Manual

Page 7

7

FORM NO. L-21277-B-1213

GENERAL RPS DESIGN GUIDELINES

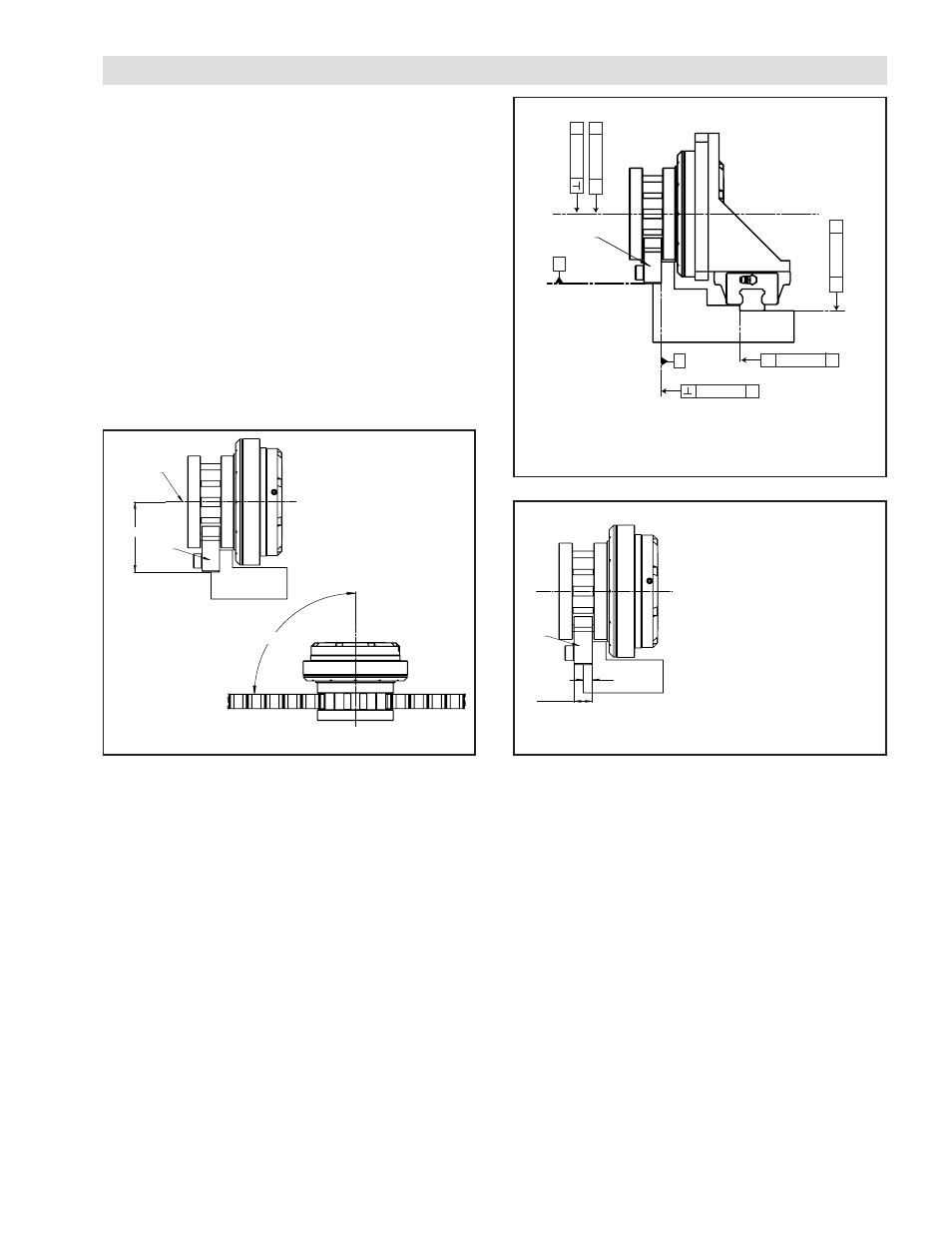

In order to minimize backlash , obtain the highest positional

accuracy, and minimize wear on the rack, the RPS must

be installed on rigid, straight, flat mounting surfaces with

the tolerances shown in Figures 3 and 4.

The following requirements must be met to ensure proper

RPS operation:

a) Mount a linear guide rail on a surface parallel to the

RPS rack mounting surface with the same flatness as

the rack mounting surface as shown in Figure 4.

b) The pinion shaft must be parallel (±0.03 mm [±0.001

in]) to the rack mounting surface opposite the rack

teeth and the angle between the pinion shaft and the

face of the rack must be 90° ±0.1° maximum as shown

in Figure 3.

Rack

0.03 mm

A

//

0.03 mm

B

0.03 mm

A

//

0.03 mm A

0.03 mm B

//

A

B

Figure 4 Tolerances

Additional dimensional detail can be found in Nexen’s

product drawings.

Parallel

HGP

Centerline

Rack

90.0° ±.1°

Figure 3 Pinion Alignment Requirements

This distance must

remain parallel within

±0.03 mm [±0.001 in].

The mounting surface for both the rack and the guiding

system must be parallel within the specifications shown

in Figure 4. This parallelism requirement is best achieved

by machining the mounting locations for both the guiding

system and rack in the same machining operation. (Refer

to SYSTEM ALIGNMENT VERIFICATION section later

in this manual.

The rack must sit on a step at

least one half the width of the

rack for proper support. The

rack should not be supported

by fasteners alone. Pinning the

rack to its mounting surface is

not recommended.

W

1/2 W

Rack

Figure 5 Rack Support Requirements

Nexen recommends orienting the rack teeth downward or

to the side so it minimizes the possibility of debris collecting

on the teeth and causing meshing interference. The rack

has 5 reference surfaces and includes all sides except the

side with the product number. The non-reference face

with the product number should not be placed against

the machine bed surfaces. Any rack ends that have been

cut must be located at the end of the run; the pinion must

not cross cut rack ends.