Nexen HGP25 969053 User Manual

Page 10

FORM NO. L-21277-B-1213

10

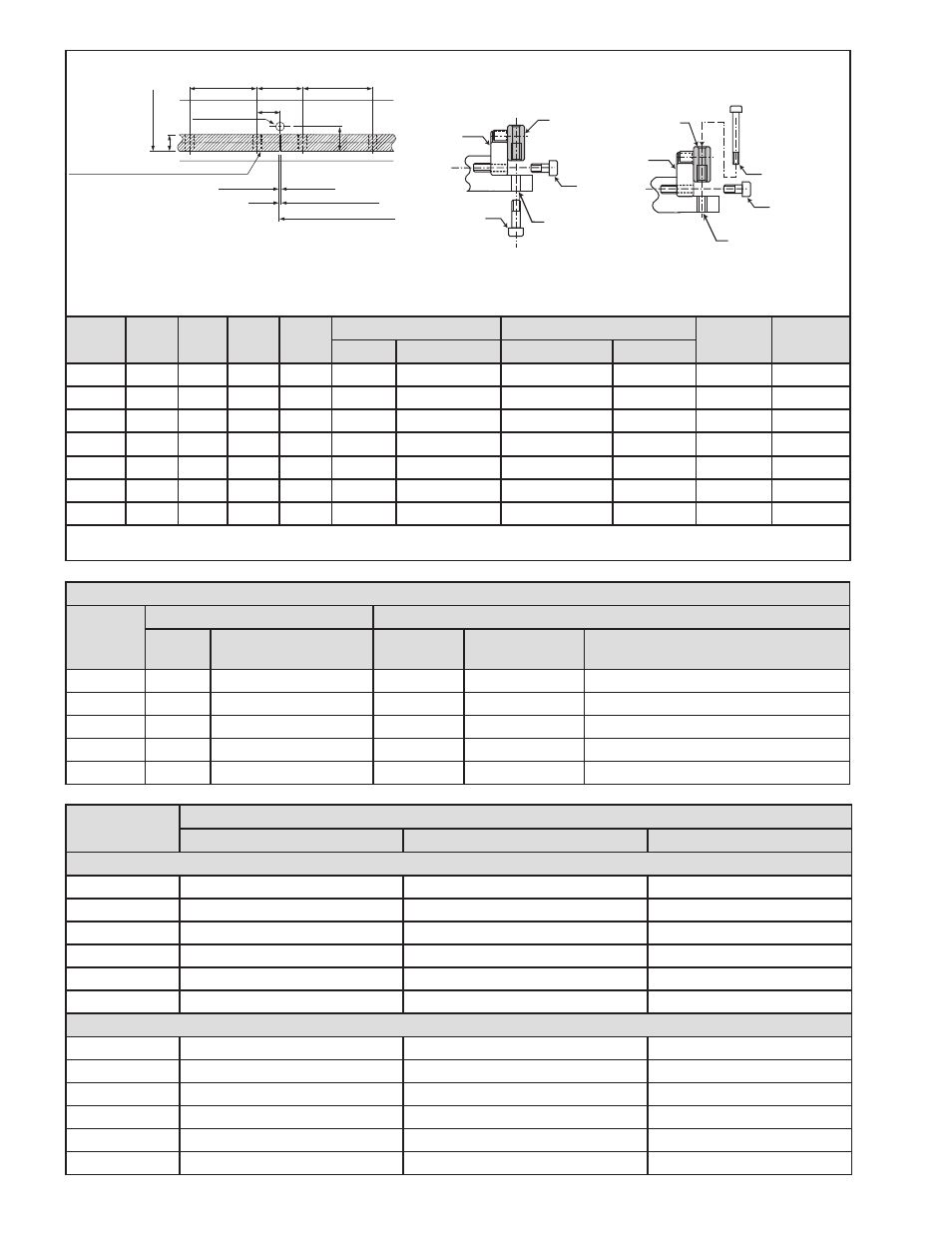

A

Second Rack

I Rack Mounting Through Hole (See Table 2)

E

Through Hole

G

Tapped Hole

First Rack

Clearance 0.1 - 0.2 mm

Second Rack Reference Level

B

A

C

E

D

Rack width

Rack Mounting Reference Surface

Positional view of the rack mounting holes (plan view)

F Alignment

Tool Mounting

Bolt

Alignment

Tool

Rack

Segment

Tapped Hole

Mounting of Alignment Tool

GEN A

Through Hole

Mounting of Alignment Tool

GEN A

H Alignment Tool

Mounting Bolt

Alignment Tool

Rack

Segment

J Rack

Mounting Bolt

J Rack

Mounting Bolt

G Tapped Hole

E Through Hole

Alignment Tool Mounting Bolt Specifications

RPS

Size

Through Hole

Tapped Hole

Bolt

Size

Tightening Torque

Initial/Final Nm [in-lb]

Thread

Depth

mm [in]

Tightening Torque

Initial/Final Nm [in-lb]

16

M6

1/5 [9/44]

M8

16 [0.63]

1/8 [7/71]

20

M8

1/8 [7/71]

M10

20 [0.79]

1/12 [9/106]

25 & 32

M10

2/28 [18/248]

M12

24 [0.94]

2/30 [18/266]

40 & 4014

M10

3/32 [27/283]

M12

24 [0.94]

3/35 [27/310]

50

M10

3/32 [27/283]

M12

24 [0.94]

3/35 [27/310]

Figure 13

Bolt Type

Mounting Material

Steel

Cast Iron

Aluminum

Rack Mounting Tightening Torque for Socket Head Cap Screws (Class 10.9 or better)

M5

8.2 Nm [73 in-lb]

5.4 Nm [48 in-lb]

4.0 Nm [35 in-lb]

M6

16 Nm [140 in-lb]

10 Nm [89 in-lb]

8 Nm [71 in-lb]

M8

31 Nm [275 in-lb]

20 Nm [177 in-lb]

15 Nm [128 in-lb]

M10

68 Nm [602 in-lb]

45 Nm [398 in-lb]

33 Nm [292 in-lb]

M12

120 Nm [1062 in-lb]

78 Nm [690 in-lb]

58 Nm [513 in-lb]

M16

196 Nm [1735 in-lb]

131 Nm [1160 in-lb]

98 Nm [867 in-lb]

Rack Mounting Tightening Torque for Stainless Steel Screws (Class 8.8 or better)

M5

5 Nm [44 in-lb]

5 Nm [44 in-lb]

4.0 Nm [35 in-lb]

M6

10 Nm [89 in-lb]

10 Nm [89 in-lb]

8 Nm [71 in-lb]

M8

19 Nm [168 in-lb]

19 Nm [168 in-lb]

15 Nm [128 in-lb]

M10

41 Nm [363 in-lb]

41 Nm [363 in-lb]

33 Nm [292 in-lb]

M12

70 Nm [620 in-lb]

70 Nm [620 in-lb]

58 Nm [513 in-lb]

M16

137 Nm [1213 in-lb]

131 Nm [1160 in-lb]

98 Nm [867 in-lb]

Table 2

Table 1

The dimensions below are nominal in mm and applicable only to standard catalog offerings. Refer to Nexen product

drawings and CAD files for your product numbers for precise dimensions. Special and cut sections of rack may not conform

to these dimensions. The RPS 10 & 12 alignment tools do not require fasteners so no data is listed for them below.

Dimensions apply to standard length rack sections. Cut lengths and customs could vary. Refer to drawings for your specific product

numbers. * Bolt length will vary based on machine design.

RPS

Size

A

B

C

D

Through Hole Mounting

Tapped Hole Mounting

I

J

E

F

G & H

H

16

96

32

16

19.5

9

M8 x 1.25

M6 x 1.00

M6-50

7

M6

20

100

100

50

25.5

11

M10 x 1.50

M8 x 1.25

M6-60

9

M8

25

100

100

50

30.5

14

M12 x 1.75

M10 x 1.50

M10-75

11

M10

32

96

32

16

36.5

14

M12 x 1.75

M10 x 1.50

M10-95

14

M12

40

120

160

80

43.5

14

M12 x 1.75

M10 x 1.50

M10-95

18

M16

4014

80

120

60

54.0

14

M12 x 1.75

M10 x 1.50

M10-95

18

M16

50

62.50 62.50 31.25

54.0

14

M12 x 1.75

M10 x 1.50

M10-95

18

M16