Nexen HGP25 969053 User Manual

Page 11

11

FORM NO. L-21277-B-1213

The order in which the HGP is assembled to the

motor, preload adjustment system, machine, or initial

engagement with the RPS rack is not critical, and should

be done in whichever order provides for the least amount

of difficulty to the machine assembler.

i

nStallation

of

m

otor

to

HGP

1. Before installing the motor into the HGP:

a. Wipe the motor shaft, pilot, and mounting face

clean. Wipe the internal pilot and motor mounting

face of the HGP clean.

b. Ensure that the HGP’s clamp collar is positioned

over the slotted portion of the motor shaft bore

such that the slots do not line up.

c. Remove clamp collar access set screw.

d. Insert the long blade of a hex bit (included) through

the clamp collar screw access hole in the motor

adapter and engage with the clamp collar screw

head.

2. Apply a serviceable thread locking compound to the

threads of the motor face mounting screws and a thin

film of anti-sieze compound to the motor shaft.

3. Slowly and gently guide the motor into the input of the

HGP. During this part of the procedure, the weight

of the motor should be adequately supported. Never

allow the motor to be suspended from HGP until the

shaft and pilot diameter are fully inserted.

4. Once the motor shaft and pilot are fully seated within

the HGP input, tighten the motor face mounting

screws according to Table 3. After the motor face

screws are tightened the clamp collar screw can be

tighten, also according to Table 3.

NOTE: Once motor has been fully assembled to HGP,

remove the hex bit from the clamp collar access hole

and save for future disassembly needs.

5. Reinstall clamp collar access set screw.

i

nStallation

of

HGP

to

P

reloader

S

yStem

or

m

acHine

1. Before installing the HGP into the preloader system:

a. Wipe the HGP pilot and mounting face clean.

Wipe the internal pilot and HGP mounting face

of the adjusting member of the preloader system

clean.

b. Wipe clean and apply a light coating of oil to any

faces of the preloader system which will slide

against one another during adjustment.

c. Apply a serviceable thread locking compound to

the threads of the HGP mounting screws. If using

the Nexen Preloader System, these screws are

provided.

d. Gently guide the HGP into the adjusting member

of the preloader system. Install HGP mounting

screws, using a star pattern while tightening to

the torque values shown in Table 3. These screws

should be tightened to 25% of this value in the first

iteration of the star pattern, 50% in the second

iteration, and 100% in the final iteration.

2. If the HGP will be installed directly to the machine

frame, clean and all the piloting faces and install using

the torques described in Step 1.d above.

HGP e

nGaGement

witH

rPS r

ack

Initial engagement with the rack may be accomplished

using one or more of the following methods, as the

machine’s design allows:

• The HGP can be initially assembled to the machine.

Set the position of the preload system’s sliding

member for a small amount of clearance (backlash)

between the pinion rollers and rack teeth. The pinion

can then be rolled onto the end of a section of rack

which has been secured. Backdriving of the HGP is

permissible.

•

A section of rack within a run can be removed to allow

the pinion to roll onto an adjacent rack as described

above, and then reinstalled.

•

If sufficient travel within the preload system exists, the

HGP can be initially assembled to the machine. Adjust

the position of the preload system’s sliding member

until the pinion rollers clear the rack tooth tips. From

it’s end face, the rack can then be slid beneath the

pinion rollers and between the pinion’s bearing flanges

into position. The preloader’s position can then shift

to attain initial engagement of the pinion rollers and

rack teeth.

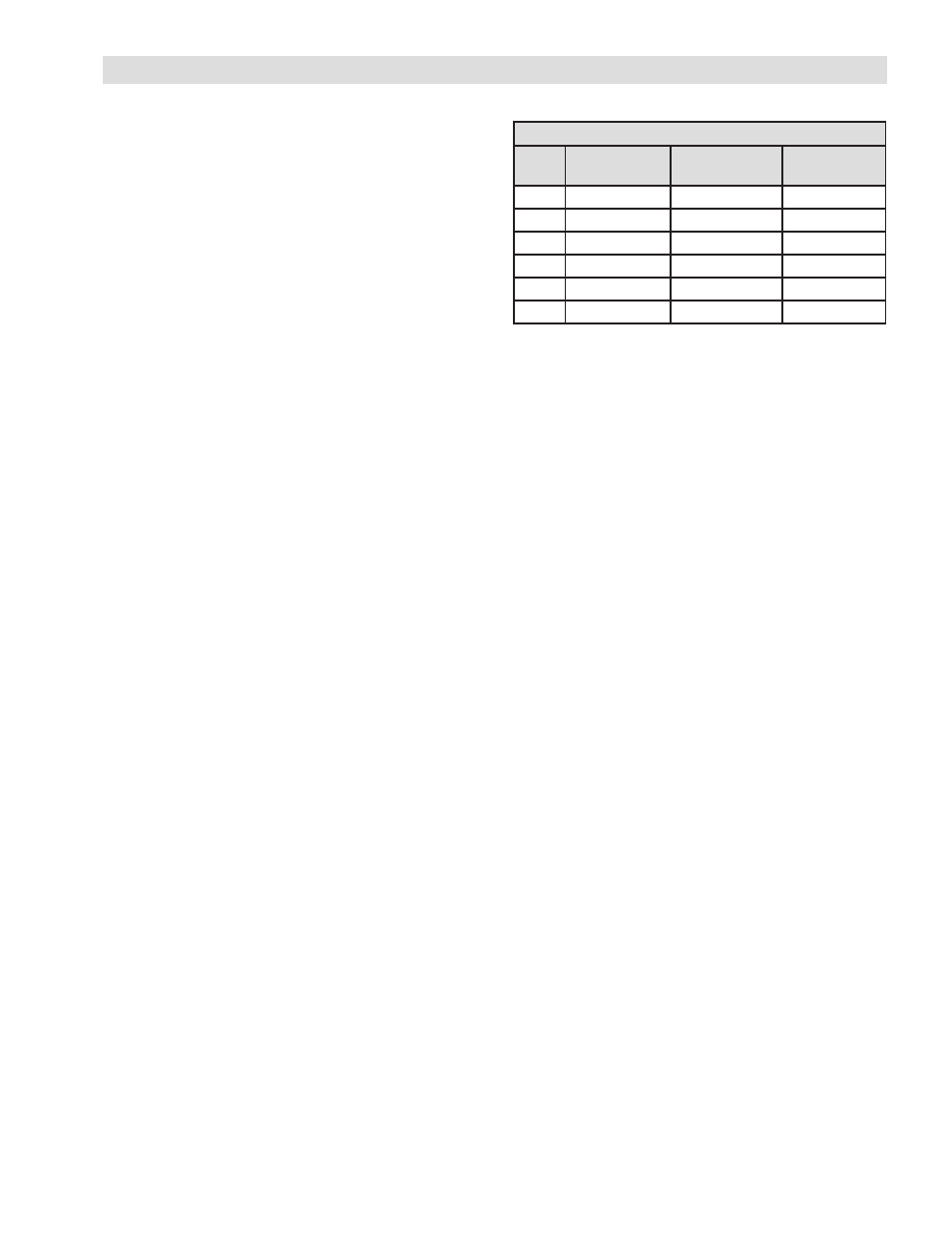

Motor Fasteners

Size

HGP Mounting

Screw Torque

Motor Mounting

Screw Torque

Clamp Collar

Screw Torque

17

32 in-lbs

28 in-lbs

18 in-lbs

25

32 in-lbs

28 in-lbs

18 in-lbs

Table 3

HGP INSTALLATION