Applying preload – Nexen HGP25 969053 User Manual

Page 12

FORM NO. L-21277-B-1213

12

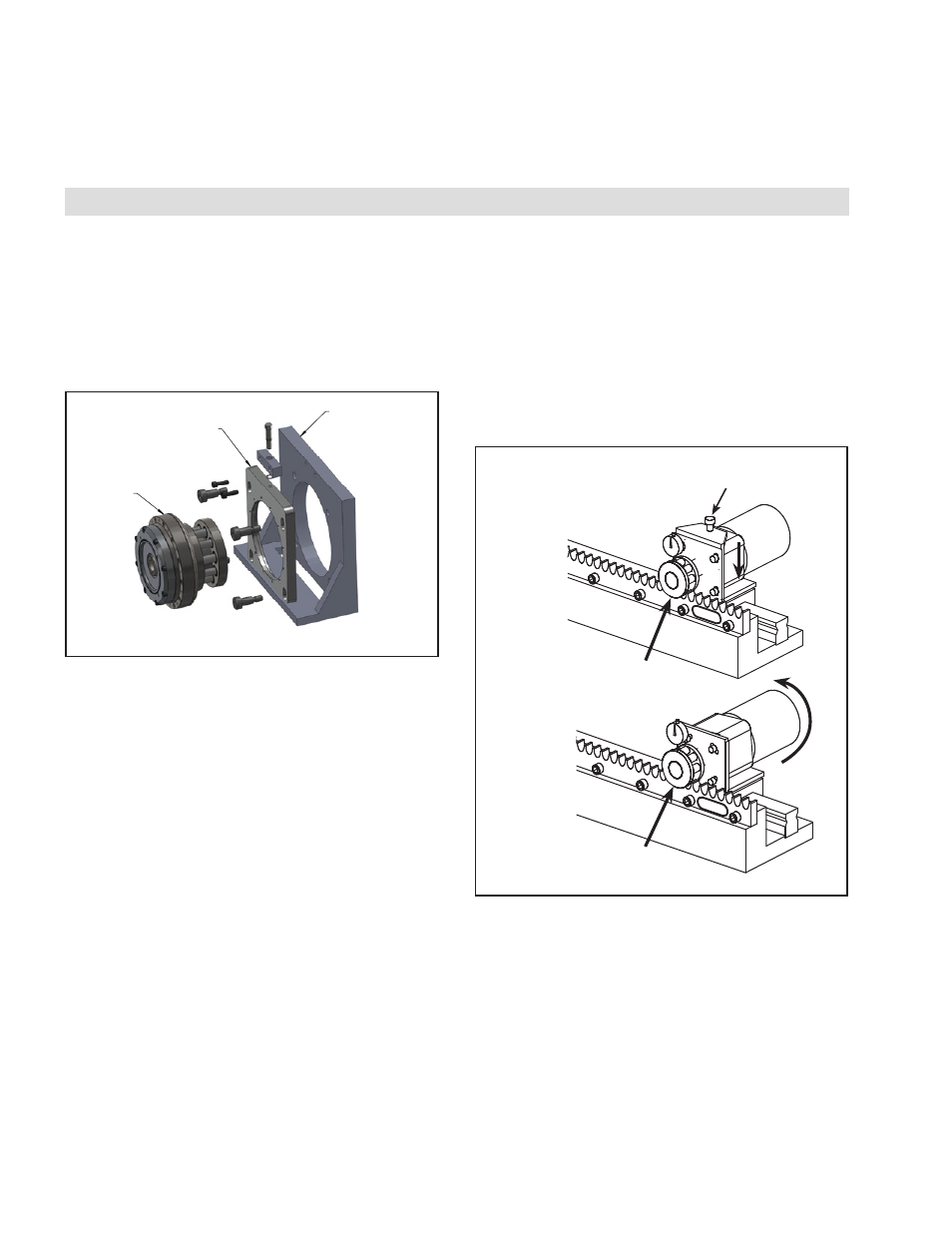

APPLYING PRELOAD

If the machine design does not already have provisions for a

preloading mechanism, Nexen offers a high precision lifting

and jacking screw style preloading system onto which the

HGP is fastened. It can simplify machine design and help

achieve the best possible system performance. A suitable

mounting surface and the correct mounting hole pattern

is required to add the Nexen preloading system to the

customer machine frame. See Figure 14.

P

reloadinG

P

rocedure

Note: Exercise care when engaging the HGP with the rack

to avoid damaging the rack teeth or pinion rollers.

1. With a dial indicator mounted on the movable carriage,

measure the height of the tooth peaks. Move the

carriage down the run taking frequent measurements

to locate the high spot in the run. This is where the

pinion preloading should be done to prevent excessive

preload from occurring elsewhere in the run.

2. Install the HGP onto the preload system’s sliding

member. Apply a serviceable threadlocking compound

to all fasteners which perform the function of locking

down the position of this sliding member. Assemble

the HGP assembly onto the machine, ensuring that

the preloader lockdown fasteners are left just loose

enough to allow the pinion rollers to be pulled in

and out of mesh with the rack teeth. For the Nexen

Preloader System, this is approximately 0.2 – 0.3

Nm [2-3 in-lbs]. If sufficient travel within the preload

system exists, the pinion can be initially engaged with

the rack by adjusting the pinion until the OD clears

the rack tooth tips.

Nexen precision preloader system product numbers

and dimensional information, and customer machine

frame mounting hole requirements can be found at

www.nexengroup.com on any of the HGP pages under

“Accessories” in the left-hand column.

To ensure optimal meshing of the pinion’s roller pins with

the rack teeth, the HGP must be preloaded to 0.010

– 0.015 mm [.0004 - .0006 in] beyond full roller/tooth

engagement.

NOTE: Do not apply excessive preload. Preloading

beyond 0.015 mm [0.0006 in] will decrease product

life, increase noise, and cause vibration. When the

RPS is properly preloaded, there will be no tangential

play between the rack and pinion when pinion rotation

is restrained and the carriage assembly is manually

forced back and forth in the direction of travel.

Refer to Figure 15 for other suggested preload methods.

Gearhead

Nexen Precision

Pinion Preloader

Customer

Machine Frame

Figure 14

Figure 15 Customer Designed Pinion Preloaders

Adjustment by Elongated Slots

(Preferred Method)

Adjustment by Eccentric Slots

Part #

Part #

Preload Adjustment

Screw

High Point In Rack Teeth

High Point In Rack Teeth

HGP e

nGaGement

witH

rPS r

ack

(

continued

)

•

If sufficient travel within the preload system exists, the

HGP can be initially assembled to the machine. Adjust

the position of the preload system’s sliding member

until the pinion OD clears the rack tooth tips.

From it’s side face, the rack can then be slid beneath

the pinion flanges and into position. The preload

adjuster’s position can then shift to attain initial

engagement of the pinion rollers and rack teeth.