Nexen HGP25 969053 User Manual

Page 14

FORM NO. L-21277-B-1213

14

DISENGAGING AND REMOVAL OF THE HGP

HGP OPERATION

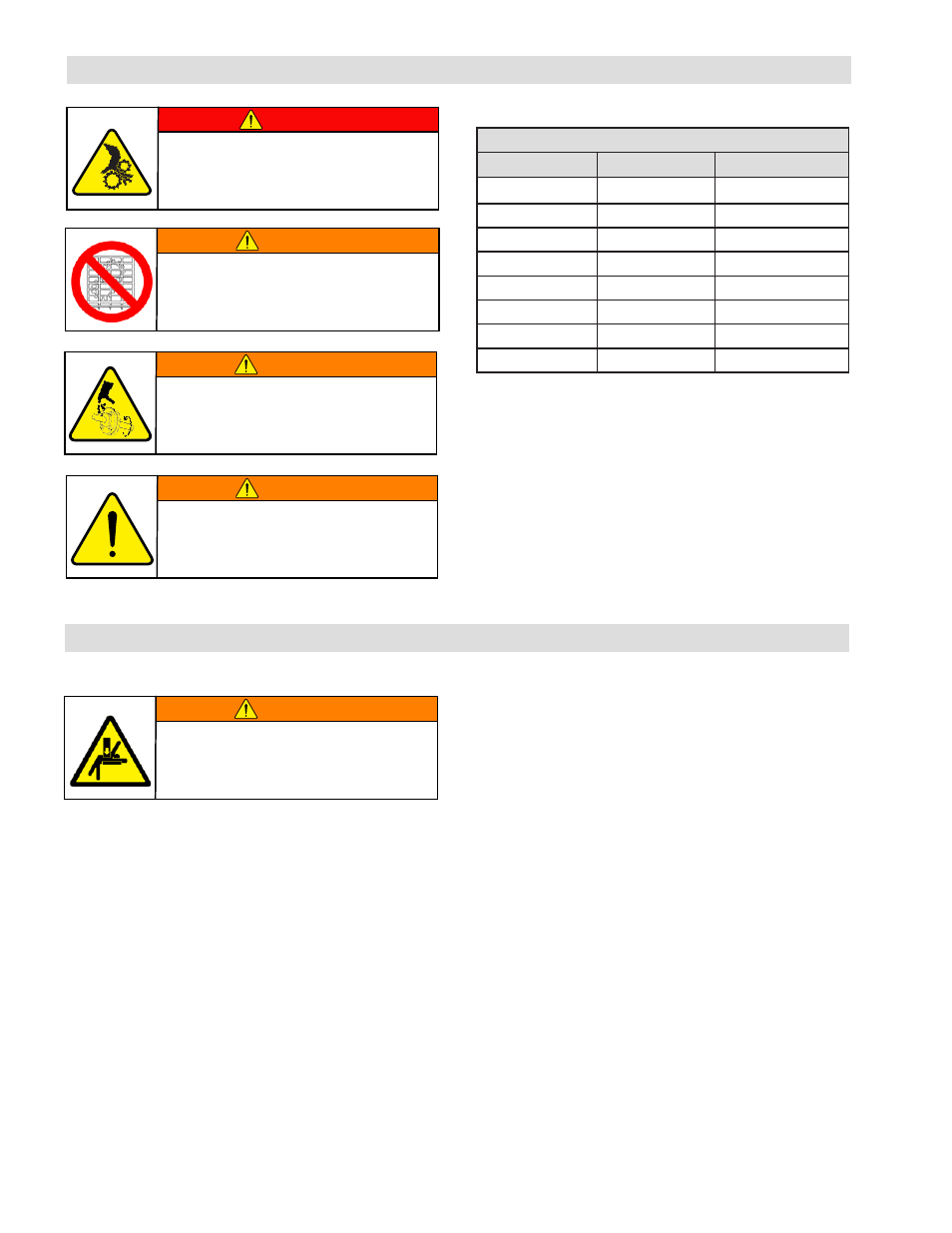

DANGER

This product has moving parts that

can crush or cut appendages. Provide

adequate spacing or guarding from any

operating product.

WARNING

Use appropriate guarding for rotating

components. Failure to guard could

result in serious bodily injury.

WARNING

Ensure proper guarding of the product is

used. Nexen recommends the machine builder

design guarding in compliance with OSHA 29

CFR 1910 “Occupational Safety and Health

Hazards”.

WARNING

Never exceed maximum operating

speeds listed for your product. (See

Table 5).

TABLE 5

Geared Pinion Maximum Speeds

Product / Ratio

Motor RPM

Pinion RPM

HGP17 / 50:1

7300

146

HGP17 / 80:1

7300

91

HGP17 / 100:1

7300

73

HGP17 / 120:1

7300

61

HGP25 / 50:1

5600

112

HGP25 / 80:1

5600

70

HGP25 / 100:1

5600

56

HGP25 / 120:1

5600

47

1. De-couple the load from the RPS carriage.

2. Disconnect the power source, ensuring that no torque

can be applied to the HGP.

3. Remove pinion preload by loosening the preload

mechanism lockdown fasteners slightly and then

turning the preload application screw(s) (or other

preload device specific to your preloading system)

to remove the pinion preload. At this time the pinion

should separate slightly from the rack teeth.

4. The HGP can then be completely disengaged from

the rack, following the reverse order of steps taken to

attain initial engagement as described in the GEARED

PINION INSTALLATION section.

5. The motor/HGP/preload mechanism assembly can

then be disassembled from the machine, following

the reverse order of assembly steps.

6. If the motor is to be disassembled from the HGP, it will

be necessary to direct a flashlight beam into the clamp

collar access hole in order to align the clamp collar

screw so that the hex key can easily be re-engaged to

loosen it. The HGP will need to be slowly backdriven

so that the input rotates to achieve this alignment.

WARNING

Failure to properly support the load

before disengaging the RPS could

cause serious harm to operators or

equipment.