Nexen HGP25 969053 User Manual

Page 13

13

FORM NO. L-21277-B-1213

Table 4

Screw

Tightening Torque

Nm [in-lb]

Preloader Screw

All Models

--

1.7 [15] Max

Shoulder Screws (Mtg. Plate)

Preloader, HG17

M6 x 1.0

17.5 [155]

Preloader, HG25

M8 x 1.25

40 [354]

P

reloadinG

P

rocedure

(

continued

)

3. Verify that pinion alignment requirements are being

met, and the rack is centered between the pinion

bearing flanges as shown in Figure 3.

4. If your preload system utilizes lifting/jacking screws

to vary the amount of preload, rotate the adjustment

screws to separate the pinion from the rack, verifying

that clearance is initially present. Clearance can be

observed in the form of system backlash. Then rotate

the adjustment screws in the opposite direction to

begin seating the pinion into contact with the rack.

When a larger amount of resistance is felt, back the

adjustment screw(s) off approximately 1/8 of a turn.

This step is critical to prepare for the setting of actual

preload.

If your preload system utilizes eccentric slots or other

methods of adjustment, rotate or shift the adjusting

member as necessary to separate the pinion from

the rack, verifying that clearance is initially present.

Clearance can be observed in the form of system

backlash. Then rotate or shift the adjusting member

in the opposite direction to begin seating the pinion

into contact with the rack. When the pinion contacts

the rack, stop. This step is critical to prepare for the

setting of actual preload.

5. Place a magnetic base dial indicator on the movable

carriage, and locate its probe on the OD of the pinion

flange such that it measures in the direction of preload

travel.

6. Apply the preload of 0.010 - 0.015 mm [0.0004 -

0.0006 in] with the preload application screw(s) (or

either preload application device specific to your

preloading system) and then tighten the preload

lockdown fasteners to their recommended torques.

See Table 4 for Nexen Preloader System torque

values. Typically the preload will change slightly when

the preloader lockdown fasteners are tightened. If

tightening the preload fasteners causes the amount

of preload to fall outside of specifications, record

how much it changed when tightening the preloader

lock down fasteners, loosen the preloading system

and repeat the preloading procedure but adjust the

initial preload (more or less) by the recorded preload

deviation. This procedure will ensure that when

the preloader lockdown fasteners are tightened the

amount of preload will remain within specifications.

7. With the pinion preloaded to specifications manually

traverse the carriage down the run (if possible),

checking for smoothness and uniformity of resistance.

If manually applied motion is not possible, use the

servo motor to traverse the carriage along the run

slowly while looking and listening for resistance to

motion.

Proper roller to tooth meshing is critical and can be verified

by two methods depending on which you find easier to

interpret:

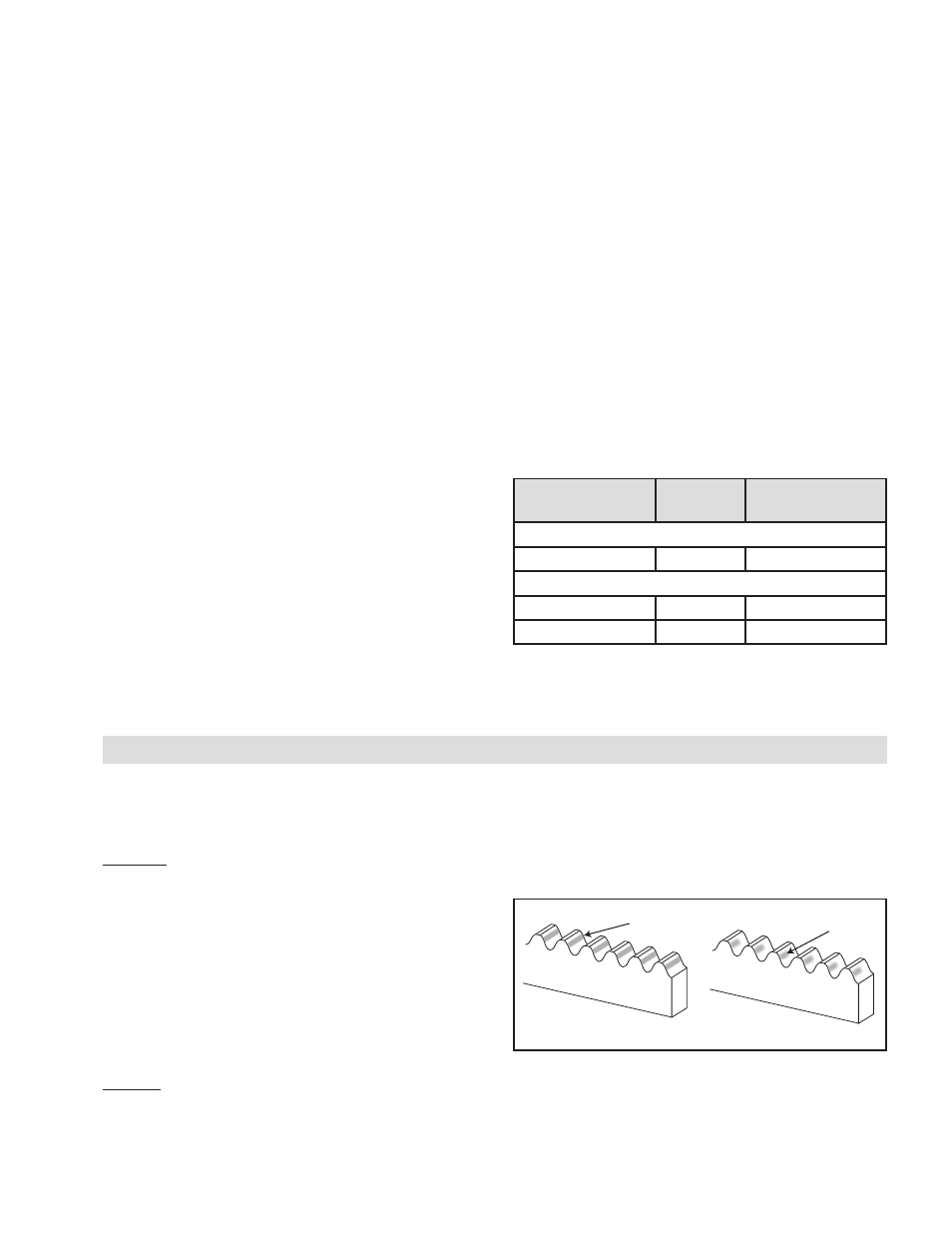

Option 1: Apply a slow drying machinists dye to the

pinion rollers and slowly move the RPS back and forth

over a short distance (about 1/2 meter). It is important the

dye remain wet so it transfers to the rack teeth and is not

depleted. Analyze the dye pattern transferred to the teeth.

If the meshing geometry is good the dye will be spread

evenly all the way across the tooth face over the middle

2/3 - 3/4 of the teeth with none at the top and bottom. If

this section is properly aligned clean off dye residue and

repeat as necessary to verify the RPS alignment over the

entire length of travel. See Figure 16.

Option 2: Apply a small amount of grease (see Lubrication

section) to each rack tooth face over 1/2 meter of rack.

Slowly move the RPS system back and forth over this

1/2 meter of travel. If the meshing geometry is good the

Good Alignment

Poor Alignment

Contact Pattern

Contact Pattern

Figure 16

grease will be completely wiped away all the way across

the tooth face over the middle 2/3 - 3/4 of the teeth with

some remaining at the top and bottom. If this section is

properly aligned clean off grease with a solvent and repeat

as necessary to verify the RPS alignment over the entire

length of travel as shown in Figure 16.

SYSTEM ALIGNMENT VERIFICATION

If the dye or grease contact pattern indicates a meshing

problem, diagnose the problem, correct it, and then

repeat the Applying Preload and System Alignment

Verification procedures.