Notice, Caution – Metalfab Electric Chain Hoist ER and NER Series User Manual

Page 31

31

§ Change gear oil at least once every 5 years. The oil should be changed more frequently

depending on the hoist's usage and operating environment. Refer to

Section 6.1

.

§ Refer

to

Figure 3-1

and

Table 3-1

to change the gear oil, remove both fill and drain plugs and allow

the old oil drain completely. Replace the drain plug and refill the gear case with the correct quantity

of new oil or until the oil level is within the range shown in

Table 6-3

.

§

NOTICE

Dispose of the used oil in accordance with local regulations.

6.3 Motor Brake

6.3.1 To keep your hoist working in optimum condition and prevent possible down time, it is recommended to

check your motor brake lining and adjustment at regular intervals.

6.3.2 Motor Brake Unit Removal - Adjustment and inspection of the motor brake requires removal of the

motor brake unit from the hoist as an assembly.

1)

CAUTION

Before proceeding disconnect the power supply and make sure the hoist is

unloaded. To keep the load chain from moving secure it by tying together the load and no-load sides

directly under the hoist using a cord or wire.

2)

Refer to

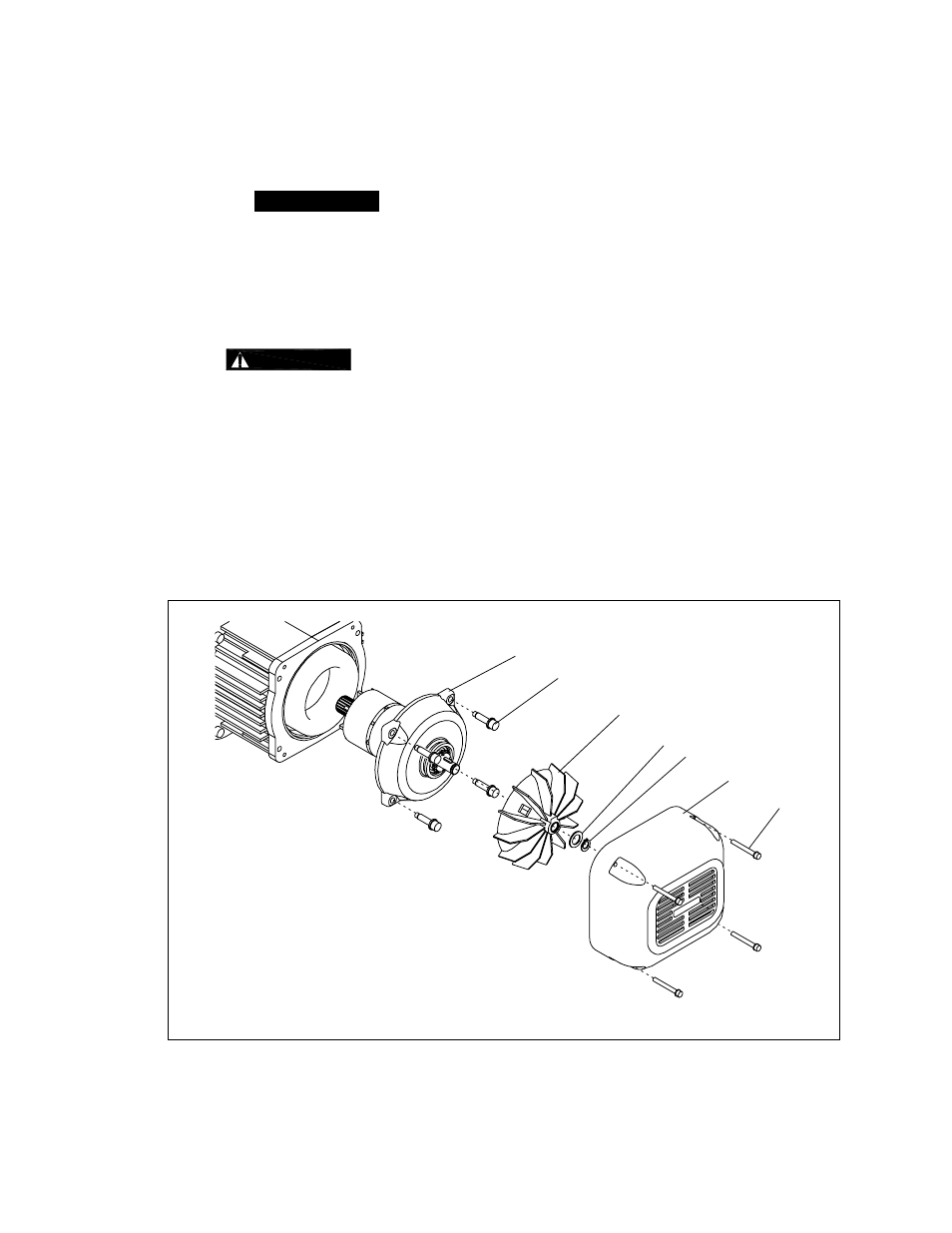

Figure 6-3

.

3)

Remove the four Fan Cover bolts (A), Fan Cover (B), Fan snap ring (C), and Fan washer (D).

4)

Pull the Fan (E) off the motor shaft using a wheel puller if necessary.

5)

Remove the four Motor Cover Assembly bolts (F) and carefully pull the motor brake unit (G) out of the

hoist.

A

B

C

D

E

F

G

Figure 6-3

Motor Brake

6.3.3 Brake Gap (G) - The Brake Gap should be measured between the Brake Drum and Pull Rotor.

Adjustment of the Brake Gap is accomplished by turning the Adjustment Nut in the center of the Motor

Cover as shown in the figure with

Table 6-4

. Do this as follows: