Warning – Metalfab Electric Chain Hoist ER and NER Series User Manual

Page 30

30

6.2 Lubrication

6.2.1

Load Chain

§ For longer life, the load chain should be lubricated.

§ The load chain lubrication should be accomplished after cleaning the load chain with an acid free

cleaning solution.

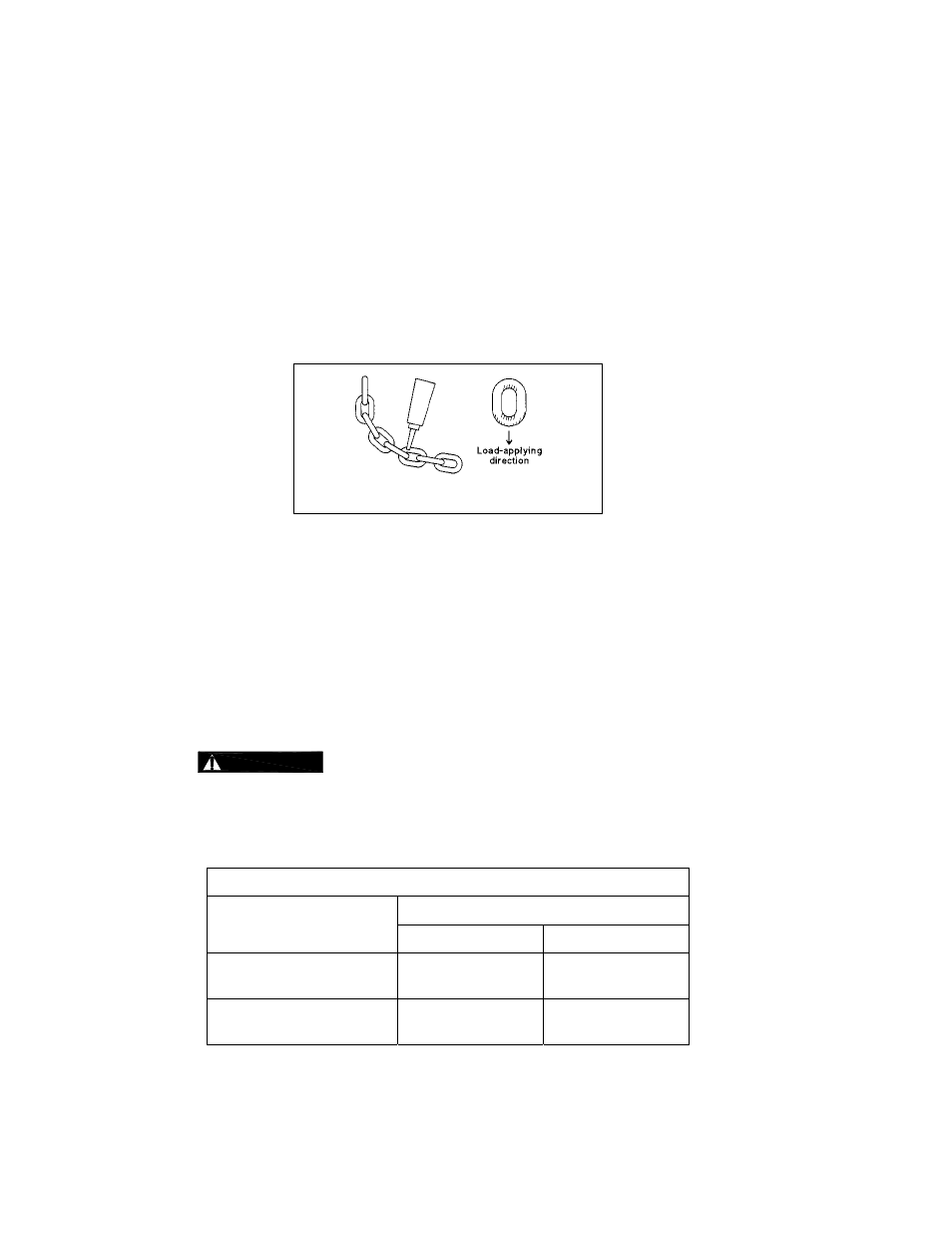

§ Apply Harrington lubricating grease (Part No. ER1BS1951) or an equivalent to industrial general

lithium grease, NLGI No. 0, to the bearing surfaces of the load chain links as indicated by the

shaded areas in

Figure 6-2

. Also apply the grease to the areas of the load chain (shaded areas in

Figure 6-2

) that contact the load sheave. Insure that the grease is applied to the contact areas in

the load sheave pockets.

§ Machine or gear oil (grade ISO VG 46 or 68 oil or equivalent) may be used as an alternative

lubricant but must be applied more frequently.

Figure 6-2

Chain Grease Application

§ The chain should be lubricated every 3 months (more frequently for heavier usage or severe

conditions).

§ For dusty environments, it is acceptable to substitute a dry lubricant.

6.2.2

Hooks and Suspension Components:

§ Hooks - Bearings should be cleaned and lubricated at least once per year for normal usage. Clean

and lubricate more frequently for heavier usage or severe conditions.

§ Suspension Pins - Lubricate at least twice per year for normal usage; more frequently for heavier

usage or severe conditions.

6.2.3 Gear

Box:

§

WARNING

Using an incorrect type/grade of gearbox oil or the wrong quantity of oil may

prevent the friction clutch from working properly and may affect the ability of the hoist to hold the

load. Refer to

Section 3.1

for the correct oil and quantity.

§ The oil level can be checked using the oil check hole on the side of the hoist body shown in

Figure

3-1

. The oil level should be in accordance with

Table 6-3

below.

Table 6-3

Criteria for Checking Hoist Gear Oil Level

Oil Level (Hoist at level position)

Capacity Code

Min

Max

Up to and including 010M

½ “ below bottom

edge of check hole

Even with bottom

edge of check hole.

010S and Up

1“ below bottom

edge of check hole

Even with bottom

edge of check hole.