Bradford White U-65T-55FR-3N User Manual

Page 18

Step 1.

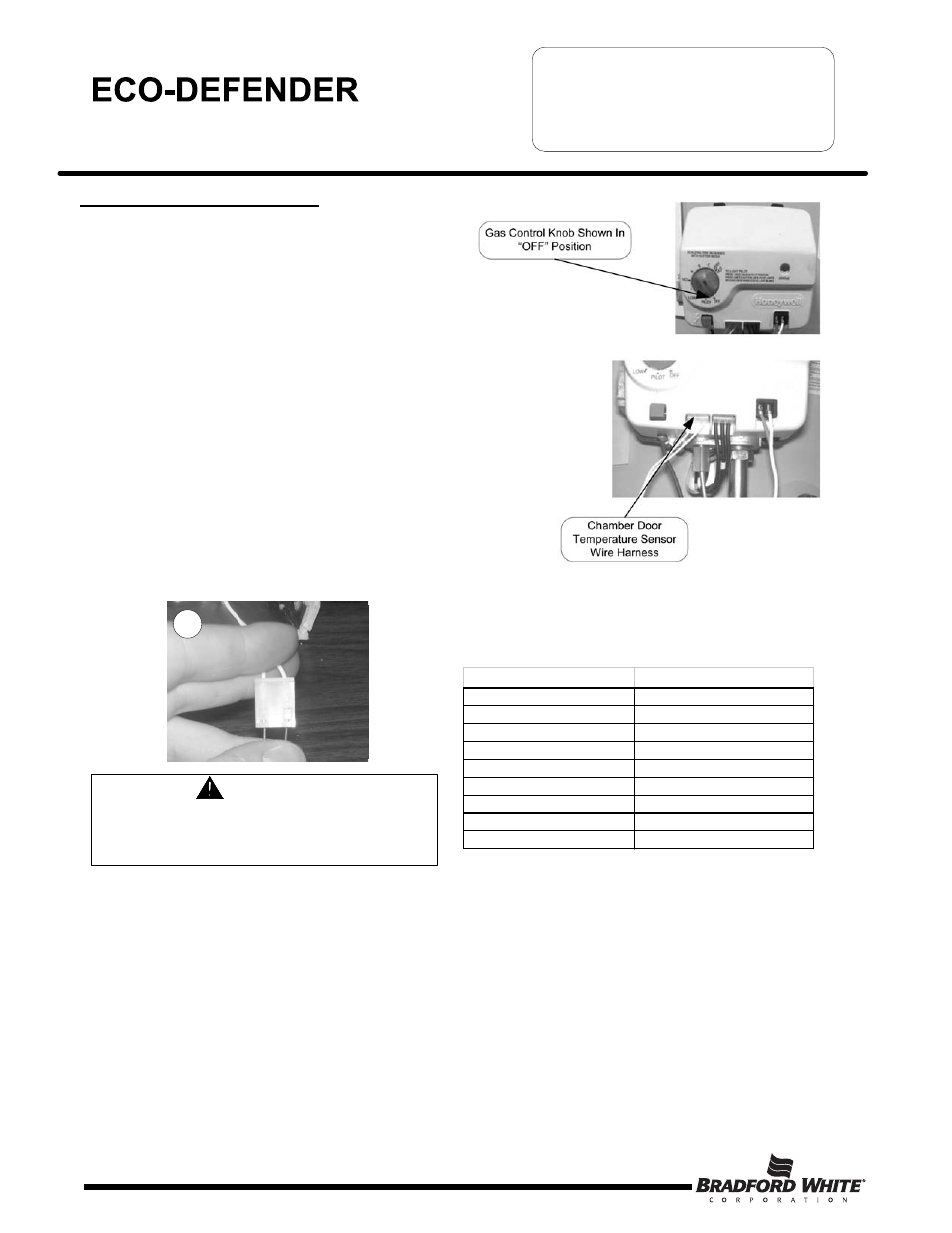

Turn the gas control knob to the “OFF” position

Step 2.

Disconnect the chamber sensor wire harness from

the gas valve.

Step 3.

Remove the chamber door temperature sensor

from the right side inner door (Phillips screw

driver).

Step 4.

Make sure that the ring terminal of the chamber

door temperature sensor is not touching any

surface. Using a multi-meter set to the ohms

setting, insert one meter probe (see caution) into

each of the wire positions (see photo 5).

Step 5.

Measure the ambient air temperature near the

sensor. Compare the ambient temperature

range to the expected resistance range on the

chart below. Note that resistance increases as

temperature decreases.

CHAMBER SENSOR TESTING

Page 18

Temperature Range (

o

F) Resistance Range (kOhms)

41-50

279-175

50-59

219-139

59-68

173-112

68-77

137-90

77-86

110-72

86-104

89-59

104-113

73-48

113-122

60-39

122-131

49-32

Sensor Resistance at Various Temperatures

SERVICE PROCEDURE ED-V

Gas Control Replacement Thermal

Well and Chamber Door Sensor

Testing and Replacement

CAUTION

DO NOT use standard multimeter probes for this test.

Doing so will damage connector. Use special pin type

electronic probes or small diameter wire pins inserted

into connector.

5

Step 6.

Replace the chamber door temperature sensor if it it out of specification.

Step 7.

Secure the chamber door temperature sensor to the right side inner door using the screw from step 3.

Step 8.

Connect the chamber door temperature sensor wire harness to the gas valve.

Step 9.

To resume operation, follow the instruction located on the lighting instruction label or the lighting

instruction located in the installation and operation manual.

Gas Control Knob Shown In

“OFF” Position

Chamber Door

Temperature Sensor

Wire Harness

18