Inflation system change and replacement, Specifications and standards – Welch Allyn DuraShock Integrated Aneroid Sphygmomanometer - User Manual User Manual

Page 4

4

Inflation System Change and Replacement

The Welch Allyn DuraShock integrated blood pressure gauge connects effortlessly to

the inflation system via a unique port connection. Therefore, only Welch Allyn

integrated blood pressure cuffs can be used with the Welch Allyn DuraShock

integrated blood pressure gauge.

1.

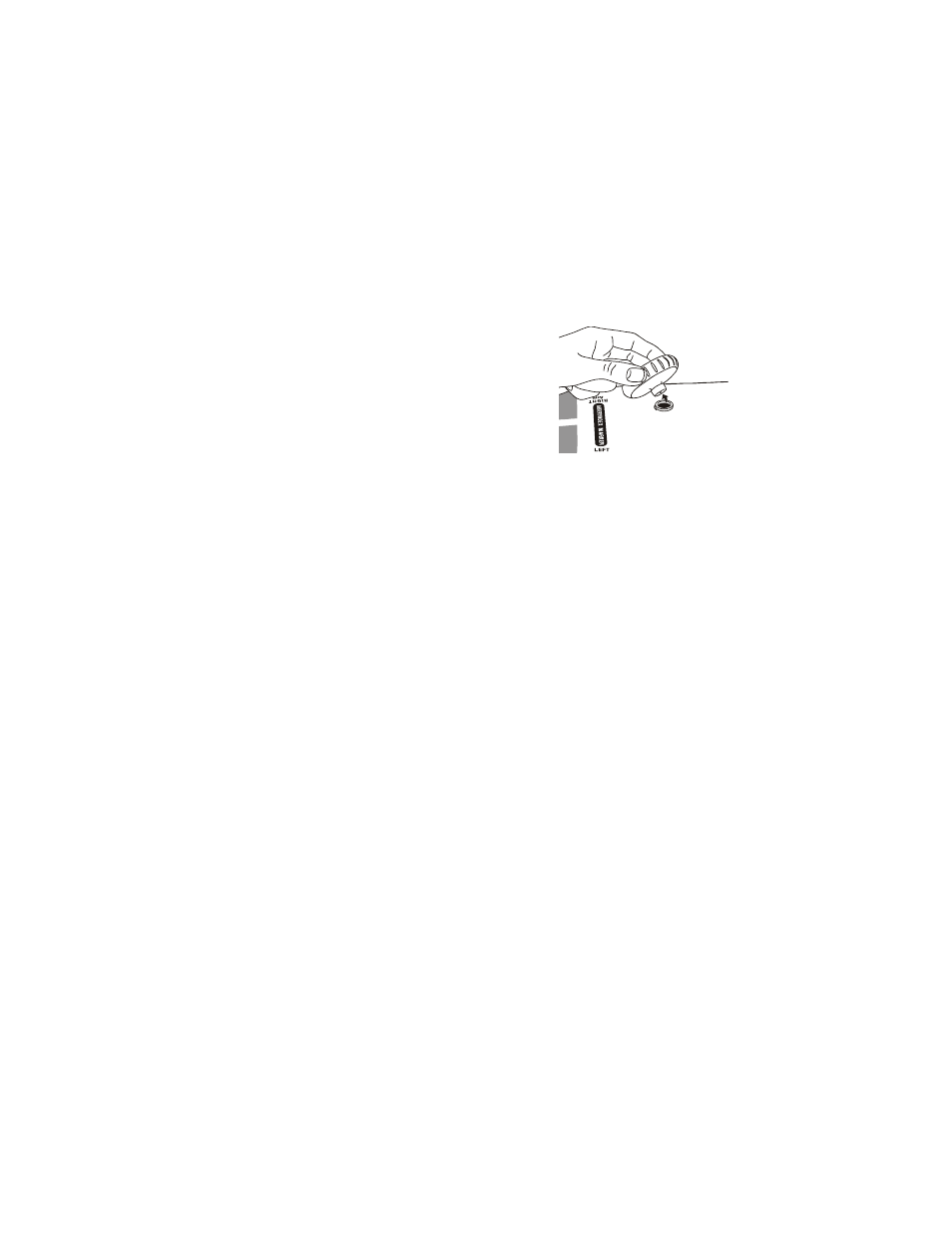

To remove the inflation system, simply grasp the

gauge and pull away from the cuff. Rotating the

gauge as it is being pulled away from the cuff will

make removal easier.

2.

To attach a new or different size blood pressure

cuff, simply press the gauge stem into the cuff port

until you feel it engage. Rotating the gauge as it is

being pressed into the cuff will make insertion

easier.

Specifications and Standards

The Welch Allyn DuraShock integrated aneroid sphygmomanometer is accurate to

±3 mm Hg and conforms to applicable sections of the following standards for aneroid

sphygmomanometers:

•

American National Standard ANSI/AAMI SP9-1994, Non-automated sphyg-

momanometers.

•

European Standard EN 1060-1: 1996, Non-invasive sphygmomanometers,

Part 1: General Requirements

•

European Standard EN 1060-2: 1996, Part 2: Supplementary requirements

for mechanical sphygmomanometers (excluding Section 7.4.3 for pointer

thickness).

•

INMETRO Technical Metrological Regulation Number 24 of February 26,

1996 (excluding Section 5.4 for pointer thickness).

This product will maintain the safety and performance characteristics specified at

temperatures ranging from 0°C (32°F) to 46°C (115°F) at a relative humidity level not

to exceed 85%.

Calibration Check of Aneroid Sphygmomanometer

Welch Allyn recommends that the calibration of aneroid sphygmomanometers be

checked using the following procedure on an annual basis.

1.

Connect gauge to a high-quality, known pressure standard

1

using a Y-connector

and the DuraShock Caliberation Connector accessor (part no. 5082-255).

2.

Pressurize gauge to slightly above 300 mm Hg.

3.

Bleed pressure down no faster than 10 mm Hg per second, stopping to check the

pressure at 300, 250, 200, 150, 60 and 0 mm Hg.